Clambrace

- Home

- Metallic Piping Supports

- Clambrace

Metallic Piping Supports

Photo Gallery

Brochure

For more information about our product, download our catalog.

Let’s Start Work

Together

The No-Weld, No-Drill Pipe Support Solution

Revolutionizing Pipe Support Installation

No Welding | No Drilling | No Epoxy | Fully Movable

Why Choose Clambrace?

- Non-Welded & Non-Drilled Installation: Avoids structural damage to beams

- Corrosion-Resistant: Fully hot-dip galvanized for harsh environments

- Rapid, Simple Installation: Requires only basic tools, no specialized labor

- Adjustable & Reusable: Easily reposition or remove as needed

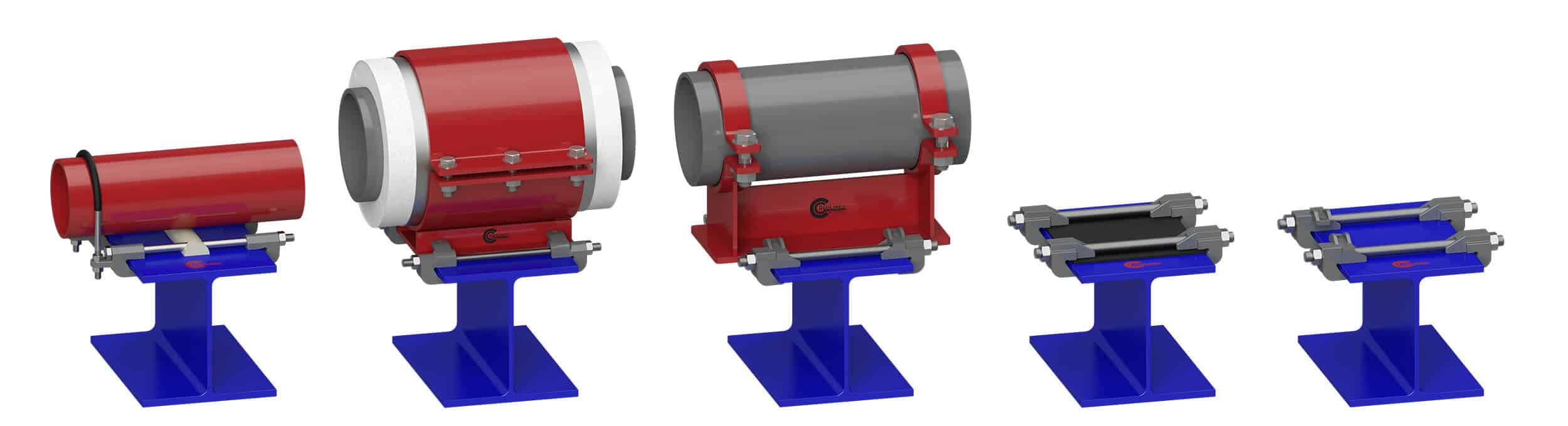

- Compatible with Various Pipe Supports: Pipe shoes, clamps, slide plates, and more

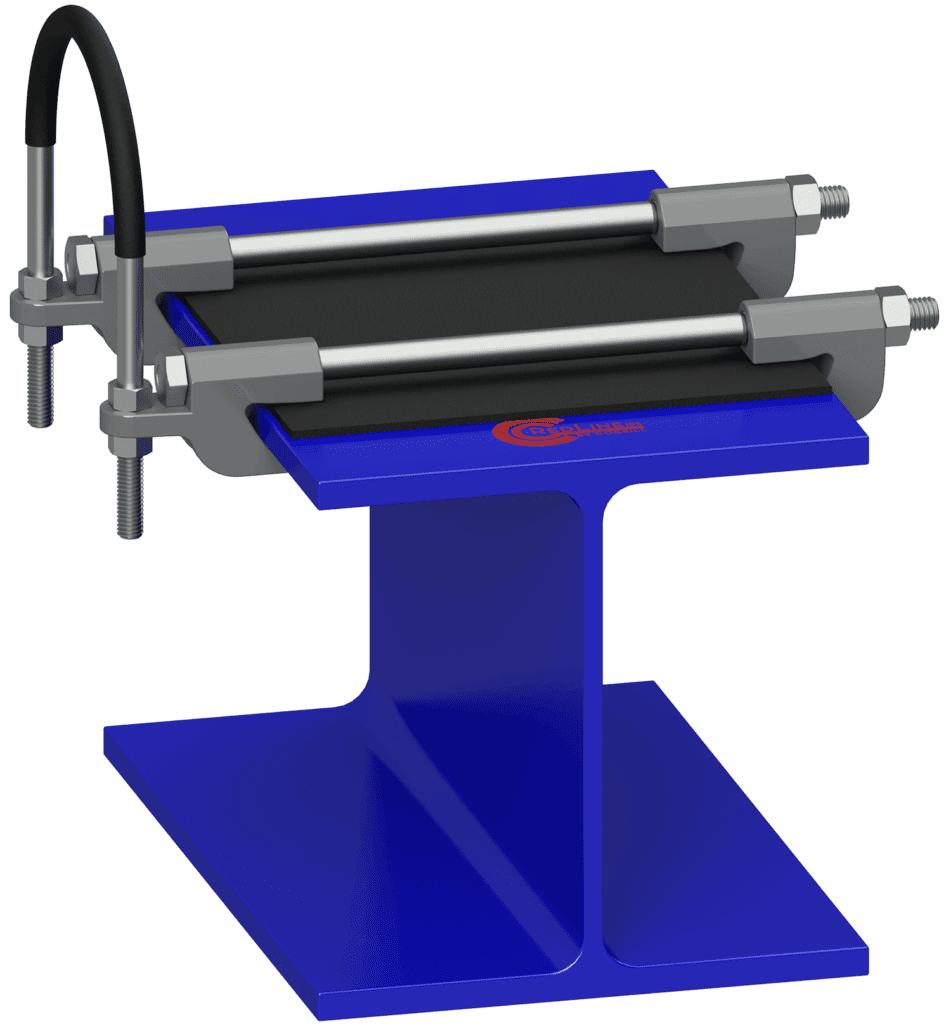

How Clambrace Works

Simple, Secure, and Strong – Installed in Minutes

- Clamp Positioning: Two Clambrace corner sets are placed on opposite sides of the beam.

- Threaded Rod Connection: Galvanized threaded rods link the corner pieces.

- Secure Fastening: Bolts are tightened, locking Clambrace into place.

- Pipe shoes

- Cryogenic shoes

- PTFE & FRP slide plates

- FRP wear pads

- Thermoplastic D-Rods

- Much more

No welding, no drilling, no adhesives—just a strong, corrosion-resistant connection.

Clambrace vs. Traditional Pipe Support Methods

| Feature | Clambrace | Traditional (Welded/Drilled) |

|---|---|---|

| Quick Installation | YES | Time-consuming & labor-heavy |

| Hot Work Permits NOT Required | YES | Required for welding |

| No Specialized Labor | YES | Requires certified welders |

| Installs in all conditions | YES | Requires dry conditions for welding |

| Protects Beam Structural Integrity | YES | Weakened by holes/welding |

| Corrosion Resistance & Protection | YES | Prone to corrosion over time |

| Pre Hot-dip galvanized | YES | Requires galvanizing |

| Adjustable & Reusable | YES | Fixed, permanent installation |

Technical Specifications

- Materials: Hot-dip galvanized forged steel corners, threaded rods, and bolts

- Beam Compatibility: Fits W4x13 to W12x40 standard American I-beams

- Threaded Rods: ASTM A307 Grade A galvanized steel

- Load Capacity: Supports heavy-duty industrial piping (specs available on request)

-

Temperature Tolerance:

- GS-52 Material: 5°F to 662°F (-15°C to 350°C)

- GS-20Mn5 Material: -40°F to 662°F (-40°C to 350°C)

- Reusability: Easily loosen, reposition, and reinstall

Industries & Applications

Clambrace is ideal for industries where welding or drilling is impractical:

- Oil & Gas Pipelines – Secure pipe supports without damaging infrastructure

- Refineries & Petrochemical Plants – Flexible and corrosion-resistant installations

- Power Generation Facilities – Safe, adjustable pipe support solutions

- Water/Wastewater Treatment – Ideal for high-moisture environments

- Industrial Manufacturing – Adaptable for dynamic production needs

Seamless Integration with RedLineIPS Solutions

Get Clambrace Today!

Upgrade your piping support system with Clambrace by Clambrace, Belgium, available exclusively through RedLineIPS in North America.

FAQ's

Typical Queries and Information

What is Clambrace?

Clambrace is a no-weld, no-drill, hot-dip galvanized metallic beam clamp system that creates a secure mounting point for pipe supports and accessories without welding, cutting, drilling, or damaging the structural beam. It preserves beam integrity, speeds installation significantly, and supports broader corrosion-control strategies by keeping coatings intact and avoiding new welds or holes in the steel.

How does Clambrace install on the beam?

Clambrace uses four forged corner pieces that clamp onto the beam flange. Two corner sets are placed on opposite sides of the beam, then connected with galvanized threaded rods. Once the nuts are tightened, the assembly grips the flange and forms a strong, fully mechanical attachment point for pipe shoes, clamps, U-Bolts, slide plates, thermoplastic half-round rods, and other support hardware—no welding, drilling, or epoxy required.

What types of pipe supports can be mounted on Clambrace?

Clambrace is designed as a mounting platform for many RedLineIPS support configurations. It can carry clamp-on pipe shoes (including cryogenic shoes), PTFE and FRP slide plates, FRP wear pads, thermoplastic half-round rods, and other metallic and non-metallic RedLineIPS supports, allowing you to build a complete, weld-free pipe support system on existing beams.

How does Clambrace compare to welded or drilled beam connections?

Traditional welded lugs and drilled connections permanently alter the beam, can damage coatings, and typically require hot-work permits and access for welding or drilling. Clambrace installs with simple hand tools, requires no hot work or beam penetration, and can be loosened, repositioned, or removed later as layouts change. That reduces permit requirements, installation time, and long-term corrosion risk while keeping structural steel intact.

Is Clambrace reusable and what temperature range can it handle?

Yes. Clambrace is fully mechanical, so it can be loosened, moved to a new location, and re-tightened or reused on other projects as long as components remain within their service limits. Standard Clambrace components are hot-dip galvanized forged steels and galvanized hardware, with typical application temperatures from about −40°F to 662°F (−40°C to 350°C), depending on the specific clamp size and material grade shown in the catalogue.

Where can I buy Clambrace in North America?

Clambrace (Clambrace / Hanwel (Belgium)) is available exclusively in North America through Cogbill Construction LLC (RedLineIPS), serving the United States, Canada, and Mexico. Contact us at:

Cogbill Construction LLC (RedLineIPS)

2325 S. Main St., Vidor, TX 77662, USA

Sales@RedLineIPS.com

(409) 768-1419