Pipe Fittings

- Home

- Metallic Piping Accessories

- Pipe Fittings

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

What are Pipe Fittings?

RedLineIPS Pipe Fittings

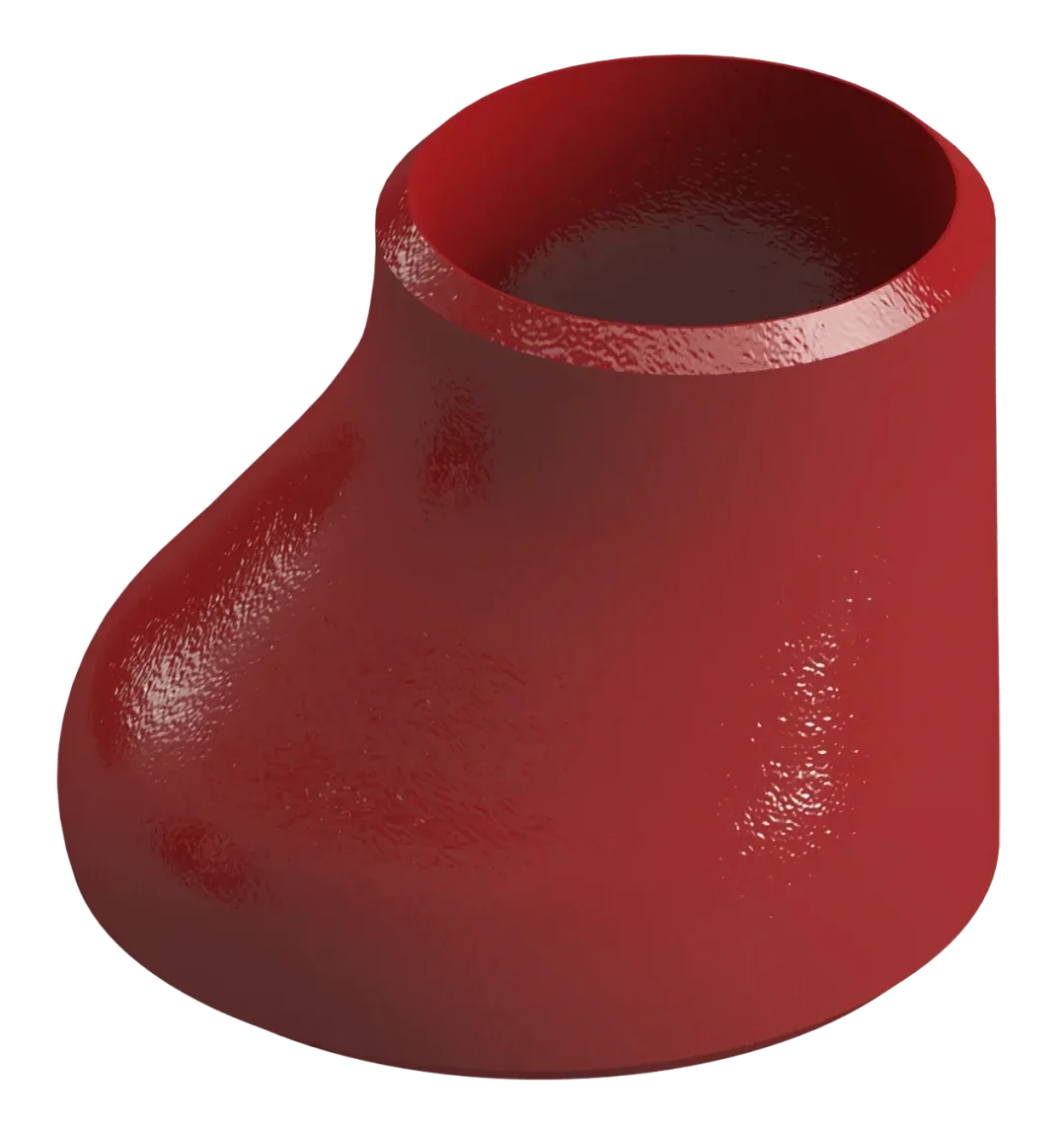

RedLineIPS Pipe Reducers

Eccentric Reducers

In eccentric reducers, an offset exists between the centerlines of the larger and smaller ends. The eccentricity, determined by the equation (Bigger end ID – Smaller end ID) / 2, allows for orientation with a flat side either up or down. Horizontal lines benefit from this flexibility, especially in scenarios like pump suction lines handling slurry or requiring gravity flow.

Reducer Orientation Considerations

Eccentric reducers’ orientation matters. When the flat side is down, it’s preferred for sleepers, pipe racks, and pump suction lines dealing with slurry. When the flat side is up, it’s ideal for pump suction lines (excluding those with slurry), aiding in initial venting through pump casing and preventing cavitation.

Types of Reducers

- Butt-welded Reducers: Follow the same standards as butt welding elbows in terms of pressure rating, dimensions, and materials.

- Socket Welded Reducers: Available in concentric type, resembling a coupling with one end socket to fit a larger diameter pipe and another to fit a smaller one.

- Screwed Reducers: Only available in the concentric type, these couplings, complying with ASME B16.11, suit larger and smaller pipes.

- Flanged Reducers: Share pressure rating, material, and dimensional standards with flanged elbows. Face-to-face dimensions adhere to the larger pipe size.

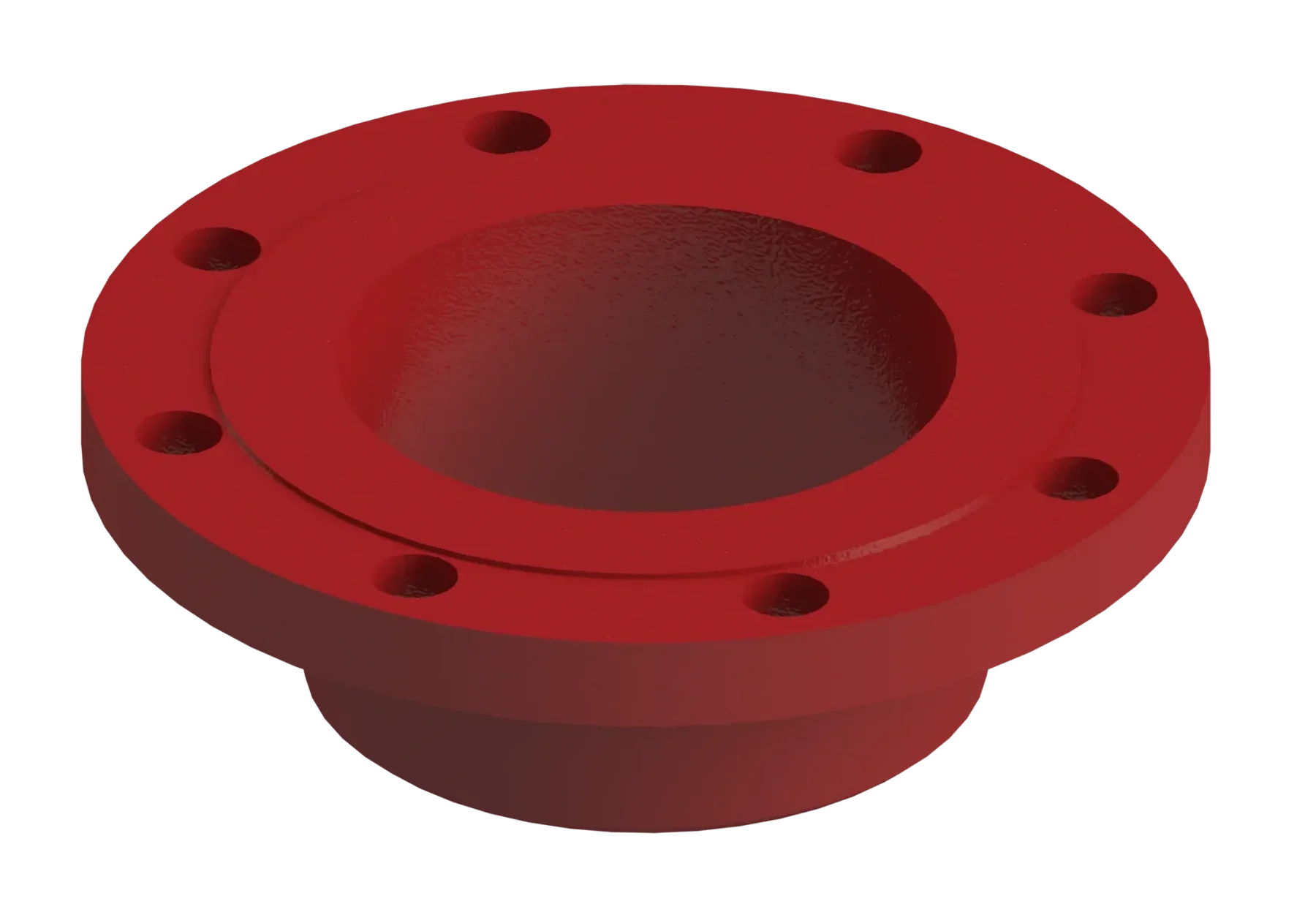

RedLineIPS Pipe Flanges

Flange Types and Features

- Weld Neck Flanges: Known for high structural integrity, they are welded to the pipe, minimizing stress concentration.

- Slip-On Flanges: Easily align and position, slipped over the pipe and then welded in place.

- Socket Weld Flanges: With a socket for welding, providing good strength and flow characteristics.

- Threaded Flanges: Ideal for low-pressure applications, facilitating easy installation without welding.

Flange Benefits

- Flexibility: Allows quick and efficient modifications to piping systems, accommodating changes in flow, direction, or equipment.

- Accessibility: The ability to dismantle and reassemble piping sections enhances accessibility for inspection, cleaning, and repairs.

- Versatility: With various types available, flanges cater to a wide range of applications, from high-pressure systems to those requiring frequent modifications.

Flange Material Composition

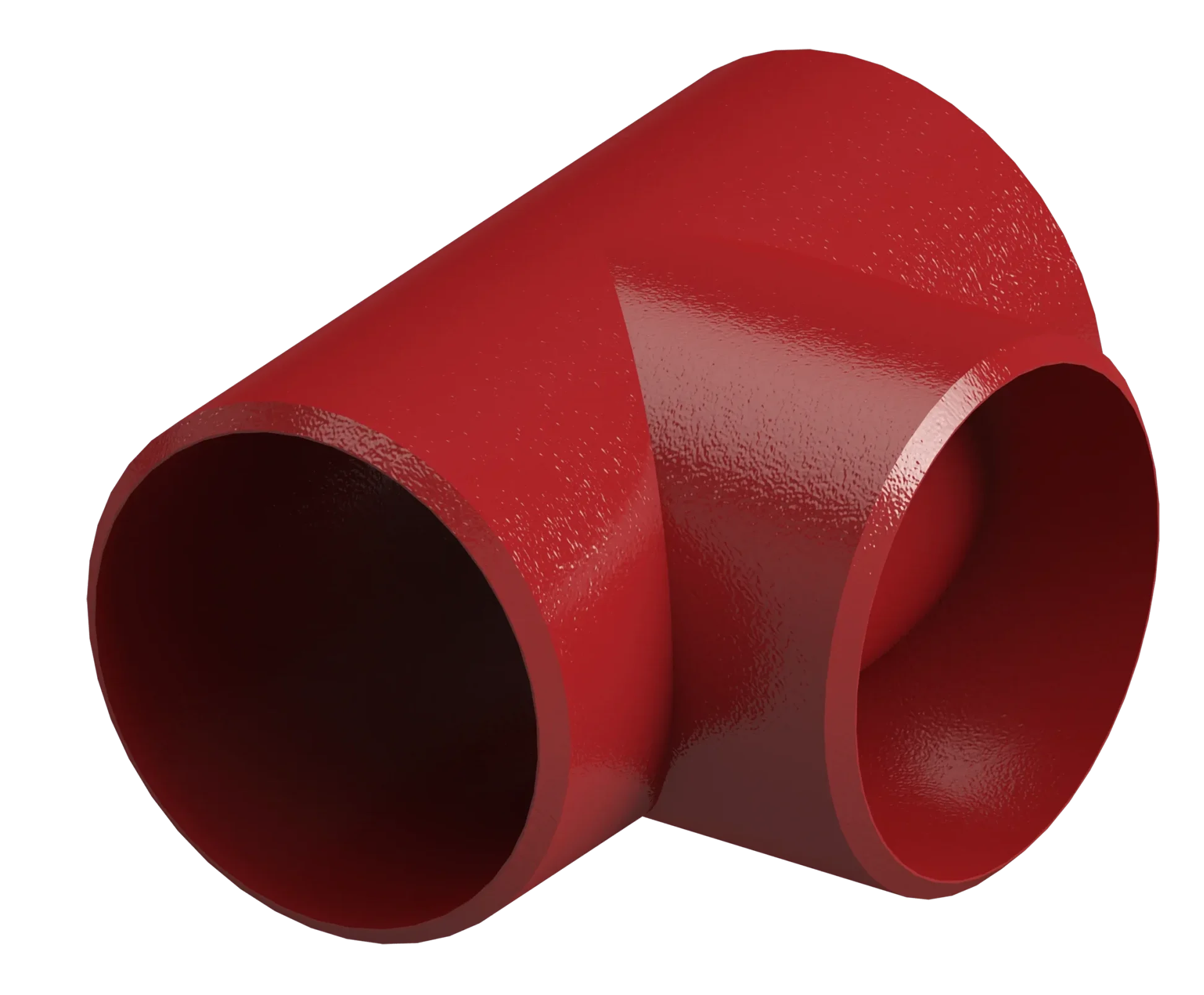

RedLineIPS Pipe Fittings

- Elbows: These fittings, available in different angles, facilitate directional changes in the pipeline, optimizing flow and navigation within confined spaces.

- Tees: Shaped like the letter "T," tees enable the creation of branch lines, splitting the flow of fluids in multiple directions.

- Caps: Placed at the end of pipes, caps seal the pipeline, preventing the escape of fluids and serving as a protective barrier.

- Crosses: Similar to tees but with an additional outlet, crosses allow for more complex piping configurations, accommodating multiple branch lines.

Benefits of Pipe Fittings

- Versatility: Pipe fittings offer flexibility in designing and adapting piping systems to meet specific requirements.

- Efficiency: Properly chosen fittings enhance the efficiency of fluid transport by minimizing friction and optimizing flow dynamics.

- Customization: With a variety of types and sizes, fittings allow for the customization of piping layouts to suit diverse industrial applications.

Why Choose RedLineIPS Pipe Fittings?

Cogbill’s RedLineIPS brand offers heavy-duty pipe fittings specifically designed for the demanding conditions of onshore and offshore petrochemical and gas installations. Proudly manufactured in the U.S.A., our products are engineered to resist abrasive chemicals, corrosion, vibration, UV light, and more, ensuring durability and reliability in harsh environments. For more information about our industrial-grade RedLineIPS pipe fittings, contact us today.