Isolation Liners

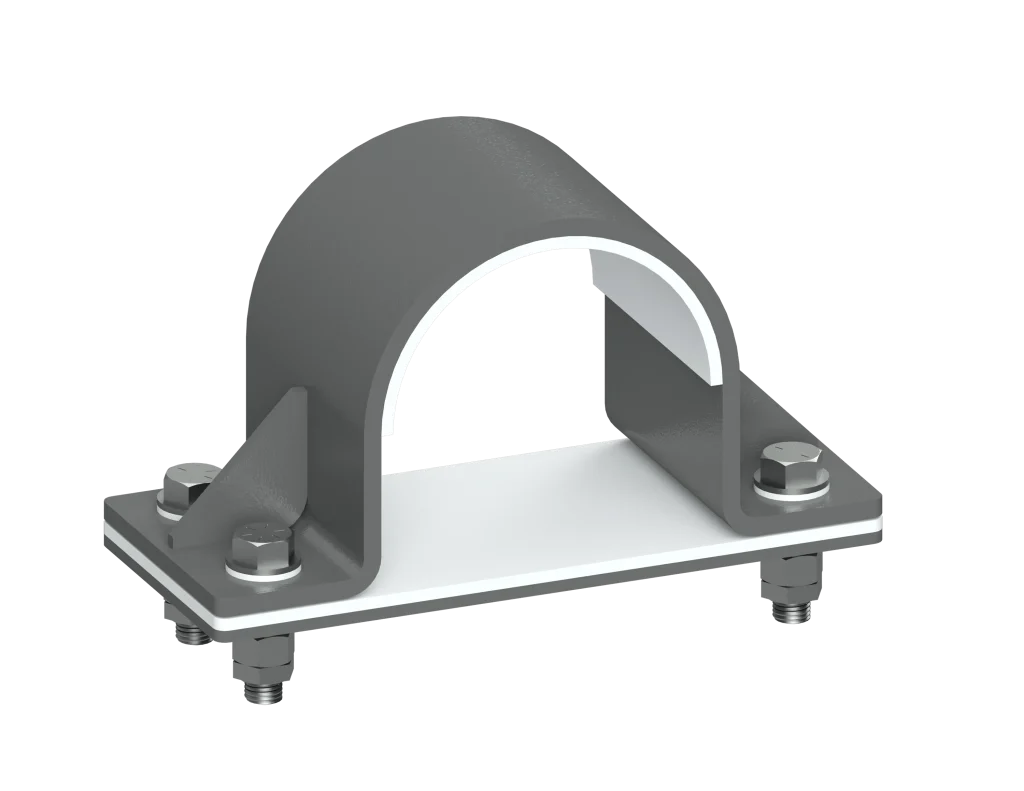

Isolation liners are protective barriers that fit onto various pipe supports to shield industrial piping systems from mechanical wear, corrosion, vibration, and noise, thus enhancing longevity and maintaining system integrity. These liners are tailored to fit different support structures and pipe dimensions.

- Home

- Non-Metallic Piping Products

- Isolation Liners

Non-Metallic Products

Photo Gallery

Let’s Start Work

Together

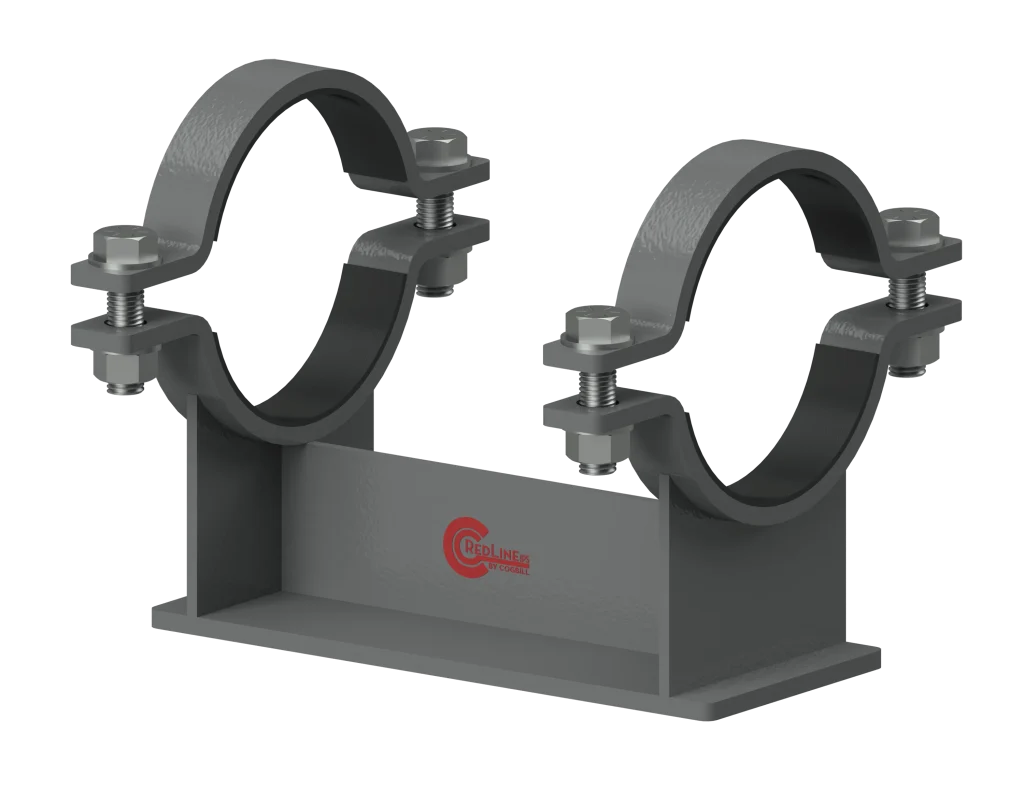

RedLineIPS Isolation Liners

Isolation liners in pipe supports offer an essential layer of protection and functionality in industrial and construction settings. Their use spans across various applications, ensuring the longevity and integrity of piping systems. One of the most significant benefits of isolation liners is their ability to dampen vibration and reduce noise. This is crucial in environments where machinery and fluid flow generate significant vibration, potentially compromising the structural integrity of the piping system and creating a noisy, disruptive atmosphere. isolation liners effectively absorb these vibrations, protecting both the pipe and its supports from wear and damage, while also contributing to a quieter and more pleasant working environment.

Additionally, isolation liners play a pivotal role in preventing corrosion—a common challenge in many industrial settings. By providing a non-conductive barrier between the pipe and its support structure, these liners mitigate the risks associated with electrochemical reactions, moisture, and other corrosive agents. This prolongs the life of both the pipes and the support infrastructure, reducing maintenance costs and downtime. Furthermore, the versatility of rubber materials allows for liners to be tailored to specific environmental conditions, including variations in temperature, exposure to chemicals, or physical abrasions.

The following is some of the liner material available for order to complement Cogbill’s RedLineIPS heavy-duty metallic supports, noting that other materials can also be made available for custom requests.

PTFE (Polytetrafluoroethylene)

PTFE is a popular choice for liners in pipe clamps, saddles, and shim block assemblies, among others, due to its excellent chemical resistance, low friction properties, and resistance to corrosion. It is highly effective in preventing metal-to-metal contact and reducing friction. PTFE is known for its non-stick properties, making it suitable for applications involving chemicals and corrosive substances.

Neoprene

Fabreeka

Cotton Duck Pad

A “Cotton Duck Pad” is typically crafted from a robust, tightly woven cotton fabric known as cotton duck. Primarily composed of cotton fibers, it offers excellent strength and durability. It is available in different weights and thicknesses, with heavier weights being thicker and more resilient. In some cases, it may be coated with materials like PVC for added water resistance or fire-retardant coatings for enhanced safety. As a liner for pipe supports, it provides protection, cushioning, and insulation.

UHMW (Ultra-High-Molecular-Weight Polyethylene)

UHMW is a type of polyethylene known for its extremely low coefficient of friction, making it an excellent choice for reducing friction and preventing wear in shim block assemblies. It provides good protection against corrosion.

EPDM (Ethylene Propylene Diene Monomer)

PVC (Polyvinyl Chloride)

Nitrile Rubber (NBR)

Comparison Between Different Types of Isolation Liners

Each type of isolation liners has its own chemical and physical properties and characteristics, making some suitable for certain applications while others may be suitable for a wide range of uses. Their capability to handle certain temperatures or mitigate noise or corrosion, for example, can make choosing the right liner for your application can be daunting. To assist you in doing this, the following table summarizes the most important aspects of each liner. If you need more help, do not hesitate to contact us.

| Rubber Liner Type | Durability | Chemical Resistance | Temperature Resistance | Corrosion Prevention | Vibration & Noise Damping | Wear & Impact Resistance | Typical Applications |

|---|---|---|---|---|---|---|---|

| Cotton Duck Pad | Moderate | Low | Moderate (-20 to 80°C) | Low | High | Moderate | Light to moderate loads, vibration isolation |

| UHMW | High | High | High (-260 to 80°C) | High | Moderate | Very High | Heavy-duty, low-friction surfaces, impact resistance |

| EPDM | High | Good | High (-50 to 150°C) | Good | High | Moderate | Outdoor, water/steam resistant applications, weather sealing |

| Nitrile Rubber | High | Excellent | Moderate (-30 to 100°C) | Moderate | High | High | Oil, fuel handling, automotive applications |

| PTFE | Very High | Excellent | Very High (-200 to 260°C) | Excellent | Low | Moderate | Chemical processing, high-temp applications, corrosion-resistant seals |

| PVC | Moderate | Good | Low to Moderate (-10 to 60°C) | Good | Moderate | Moderate | General industrial, construction, corrosion-resistant applications |

| Neoprene | High | Good | Moderate to High (-40 to 120°C) | Good | High | High | Weather resistant, sealing, cushioning, marine applications |

| Fabreeka® | Very High | Moderate to Good | Moderate to High (-50 to 120°C) | Moderate to Good | Very High | High | Shock absorption, heavy machinery, vibration and noise damping |

Choosing a RedLineIPS Isolation Liner Material

The choice of liner material depends on factors such as the specific application, the type of chemicals or substances the shim block assembly will be exposed to, and the environmental conditions. It’s important to select a liner material that offers the right balance of corrosion resistance, vibration damping, and noise reduction to meet the requirements of the piping system and the surrounding environment.

For more information on all RedLineIPS liners and their suitability for your specific needs for pipe supports, contact us today.

FAQ's

Typical Queries and Information

What are isolation liners and why are they used in pipe supports?

Isolation liners are non-metallic pads or sheets installed on pipe supports (clamps, saddles, shoes, shim blocks, guides, etc.) to separate the pipe from steel, reduce friction, damp vibration and noise, protect coatings, and reduce wear at the pipe-support interface.

How do isolation liners help with CUPS (corrosion under pipe supports)?

By breaking metal-to-metal contact and protecting the pipe coating from abrasion, liners reduce galvanic effects and slow the formation of corrosion cells at the support interface. They also help reduce the crevice-style “trap” conditions that allow moisture and salts to stay concentrated at the support point.

How do I choose between PTFE/UHMW (low friction) and rubber/Fabreeka/cotton duck (damping)?

If sliding is the priority (thermal movement, long travel, controlled slip), PTFE or UHMW are typically used for low friction and wear resistance. If vibration and noise control is the priority, elastomers like neoprene/EPDM/NBR, along with Fabreeka and cotton duck pads, are often selected because they absorb energy and reduce transmitted vibration. In many real installations, the best solution is a combination—damping where you need isolation and a low-friction surface where you need movement.

What temperature ranges can isolation liners handle?

Temperature capability depends on the liner material. PTFE is commonly used for higher-temperature sliding applications, UHMW is used for low-friction wear in moderate-temperature service, and elastomers (EPDM, neoprene, NBR) are selected based on their specific temperature and fluid exposure limits. For critical temperature services, the project spec and liner grade should be confirmed so the liner compound matches the actual operating conditions at the support.

How do I select/specify the right isolation liner for my project?

Provide the support type (clamp/shoe/saddle/shim block), pipe size, expected movement (none/limited sliding/high travel), load level, operating temperature at the interface, and the environment (outdoor/coastal/washdown/chemical/oily). With that, Cogbill can suggest the liner material—or layered combination—to the service requirements and the support detail on your drawings.