RIBS System

- Home

- Non-Metallic Piping Products

- RIBS System

Non-Metallic Products

RIBS BENEFITS

- MINIMIZES POINT- LOADING BY INCREASING LOAD DISTRIBUTION BY UP TO 500%

- MODULAR SYSTEM CAN BE SUPPLIED IN PRE-CUT LENGTHS, OR FIELD-ADJUSTED FOR MAXIMUM PRECISION

- RIBS PROVIDES POSITIVE ENGAGEMENT OF THERMOPLASTIC BARS TO ELIMINATE THE RISK OF FAILURE

- COMPATIBLE WITH MOST THERMOPLASTIC BARS FOR EASY RETROFITS

- EASY INSTALLATION, CAN BE BONDED, OR DRILLED AND BOLTED

- ELIMINATES THE NEED TO DRILL HOLES IN BEAMS, IN RODS, OR BOTH

- MAINTENANCE-FREE PERFORMANCE

- SAFER, STRONGER, LASTS LONGER

- NO SKILLED WELDERS OR HOT WORK PERMITS REQUIRED

- INSTALL ON LIVE LINES, SYSTEM SHUTDOWN NOT REQUIRED

- ACCOMMODATE ANY PIPE SIZE

Brochure

For more information about our product, download our brochure.

Let’s Start Work

Together

RedLineIPS RIBS System

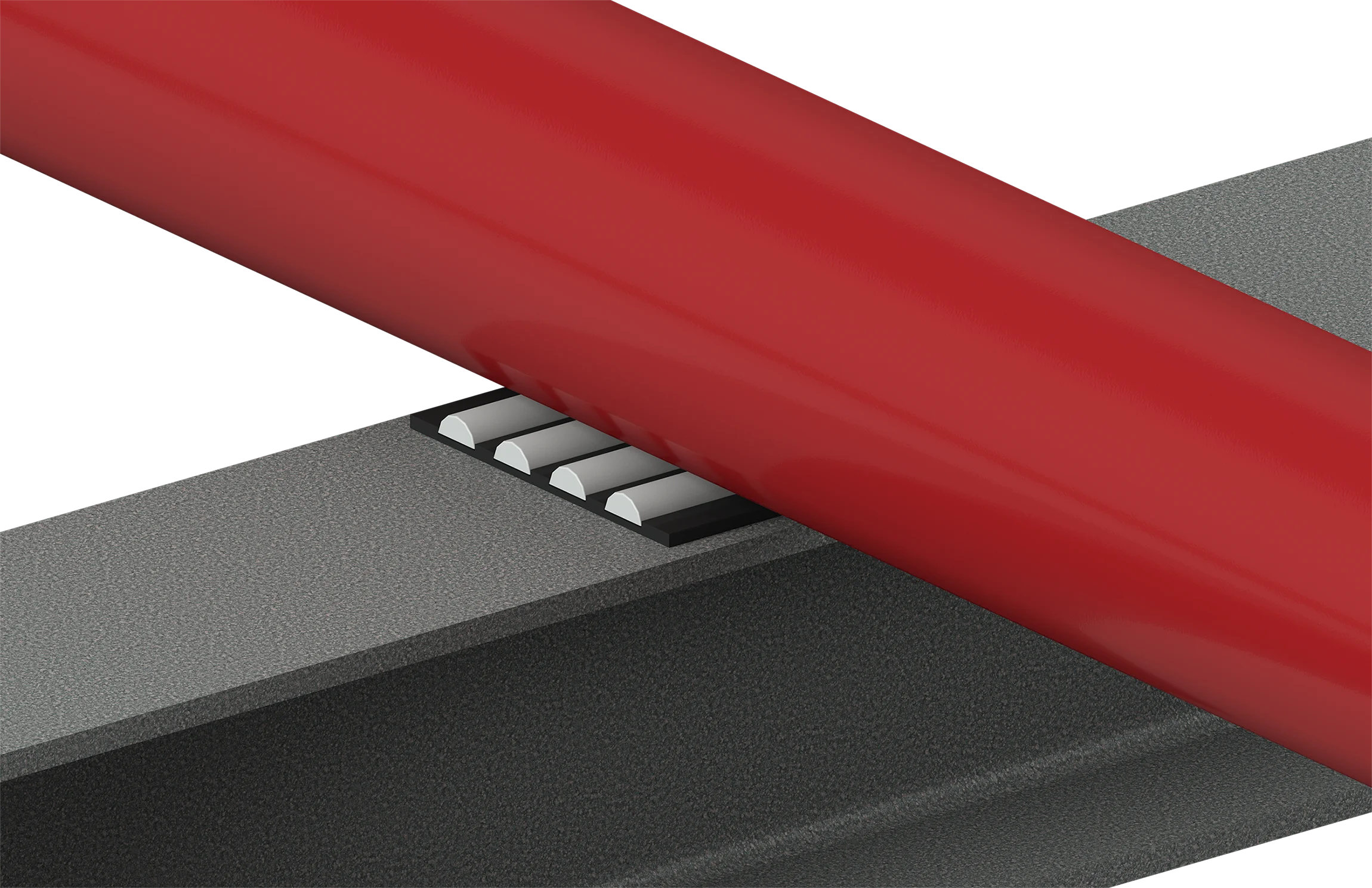

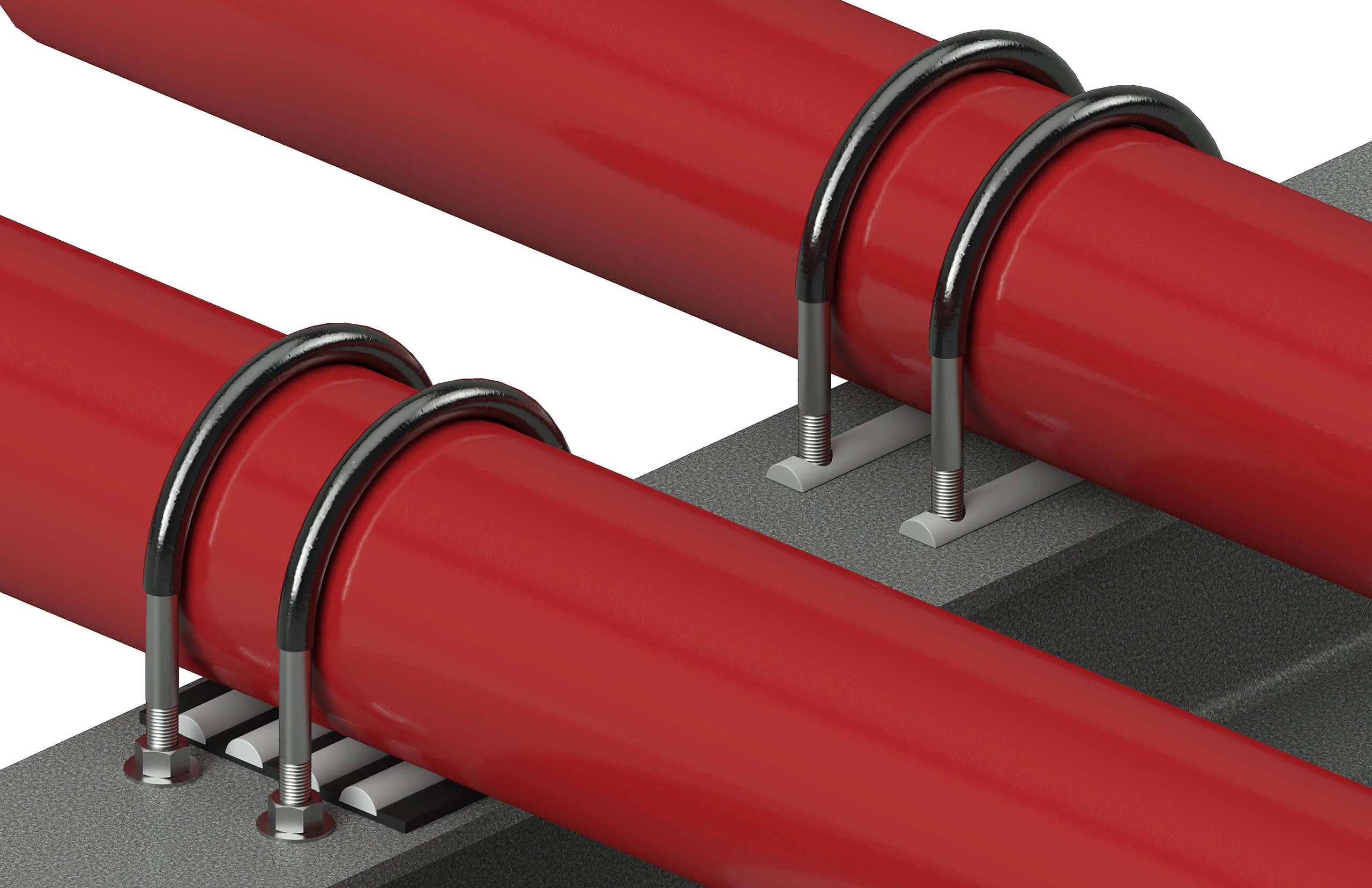

Additionally, the system’s tray feature offers a streamlined method to secure the rods without the need for U-Bolts, which typically require drilling into the rods—a process that could weaken their structural integrity by removing material and possibly introducing cracks. Utilizing our tray system alongside a bonding agent, such as a two-part epoxy or VHB tape, also negates the need to drill into the support beams. This method not only fortifies the installation with up to 2,500 psi of shear strength but also expedites the installation process considerably.

RIBS System Components

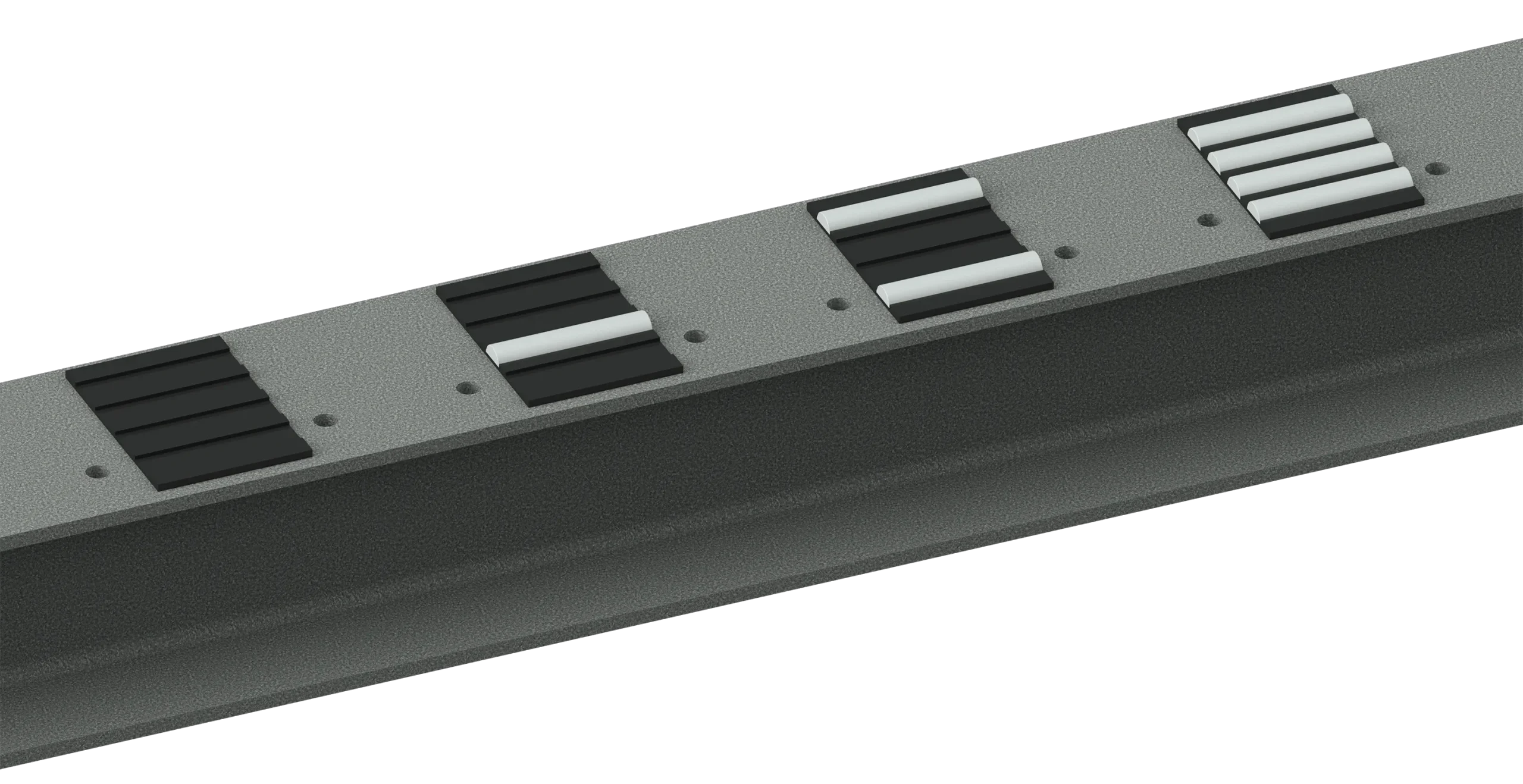

Fiber-Reinforced Plastic (FRP) Tray

The RIBS trays are crafted from the same FRP material used to manufacture our FRP Wear Pads and the SmartPads. They feature layers of continuous strand mat, infused with high-quality vinyl ester resin, making them UV stable and suitable for demanding environments, such as coastal and offshore installations. They can be manufactured to any size, and multiple trays can be stacked next to each other to create larger trays. These trays have been load-tested to accommodate pipes of any size and weight, offering custom sizes.

FRP Tray Features

- Durability and Construction: Fabricated using continuous strand mat, enhanced with vinyl ester resin lamination for superior durability.

- Environmental Resilience: Features UV resistance and has undergone rigorous load testing, ensuring peak performance in demanding environments such as coastal and offshore locations.

- Vibration and Impact Mitigation: Crafted to absorb vibrations and improve impact resistance, promoting both stability and extended service life.

- Customization Options: Offers customizable dimensions (length, width, and thickness) to precisely align with specific project needs.

- Temperature Adaptability: Capable of enduring extreme temperature fluctuations, from -60°F to 400°F (-51°C to 204°C), making it versatile for diverse operational scenarios.

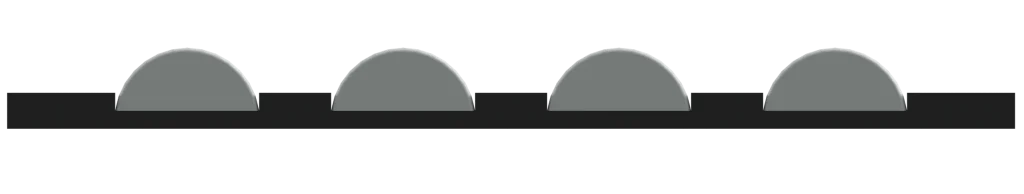

RedLineIPS Plastic Half-Round Rods

RIBS Rods Features

- Thermoplastic Material: Crafted from a robust thermoplastic, offering longevity and resilience.

- High Corrosion Resistance: Exceptionally resistant to chemical and environmental degradation.

- Temperature Range: Effective across a broad temperature spectrum of -67° to 230°F (-55°C to 110°C), maintaining integrity in extreme conditions.

- Load Capacity: Engineered to support heavy loads without compromising structural integrity.

- Impact and Compression Strength: High resistance to impacts and compressive forces, ensuring durability under stress.

- Flexural Strength: Maintains shape and support even when bent or flexed.

- UV Stability: Resistant to ultraviolet light, preventing material breakdown over time.

- Low Moisture Absorption: Minimizes swelling and deterioration in wet environments.

- Electrical Insulation: Excellent insulator, reducing the risk of electrical interference.

- Abrasion Resistance: Withstands wear and tear, ensuring long-term performance.

Why Choose RedLineIPS RIBS?

- Superior Corrosion Resistance: Our high-grade, corrosion-resistant polymer rods ensure your piping systems are well-protected against moisture, chemicals, and environmental stressors.

- Innovative Design: The unique minimal contact design reduces the risk of moisture entrapment and promotes optimal airflow around piping surfaces, extending the lifespan of your infrastructure.

- Unique Tray Design: Allows for quick installation of the rods without compromising their structural integrity.

- Versatile Applications: Suitable for a wide range of industries, our system is designed to withstand extreme temperatures and harsh chemical exposures, offering robust performance in any setting.

- Ease of Installation: Our streamlined installation process using our unique tray system minimizes downtime and simplifies maintenance, making RedLineIPS RIBS a cost-effective choice for modern businesses.

- Sustainable Solution: Embracing sustainability, our durable and recyclable rods support your eco-conscious business values, offering a long service life.

Ready for RIBS?

Elevate your corrosion prevention strategy with RedLineIPS RIBS system. Contact us today to explore our products and discover how we can contribute to the success of your business. Our team is ready to provide you with the necessary information and support, helping you make the most informed decision for your piping systems.

FAQ's

Typical Queries and Information

What is the RedLineIPS RIBS System?

RIBS (RedLineIPS Integrated Bar System) is an FRP tray-and-rod support interface that captures thermoplastic half-round rods in guided grooves so the pipe rides on multiple rods instead of on steel, reducing metal-to-metal contact at support points while also reducing point-loading caused by using a single rod.

How does the RIBS System help with CUPS and external corrosion?

RIBS lifts the pipe off the steel contact surface and removes the tight crevice that forms when a pipe sits directly on a beam. By creating a non-metallic interface at the support point, it reduces common conditions that drive corrosion under pipe supports (CUPS), especially in wet or washdown environments. The use of multiple rods spreads pipe load over multiple rods, reducing point-loading and thus protecting the pipe’s protective paint coating.

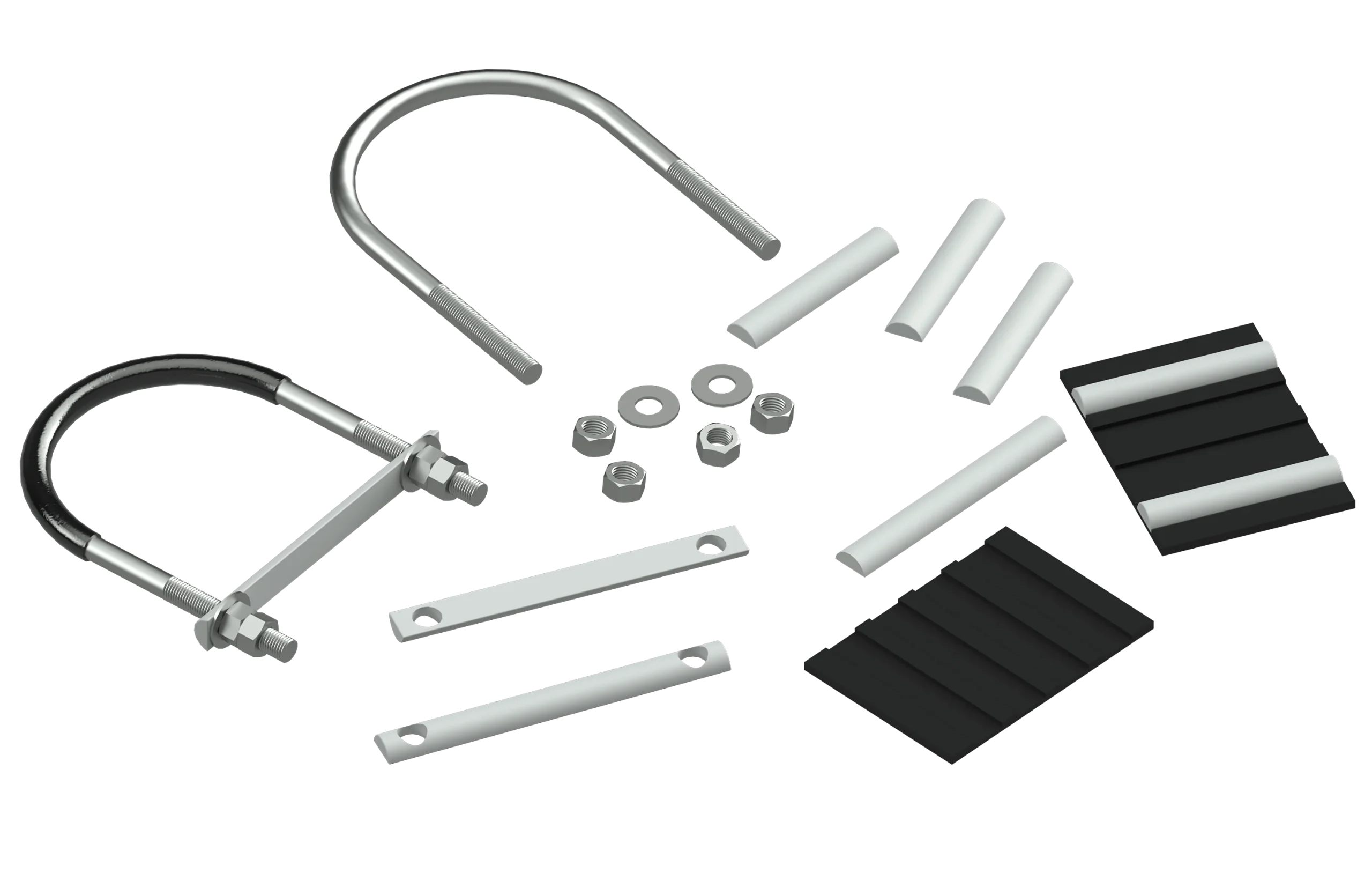

What are the main components of the RIBS System?

The system has two parts: an FRP tray with formed rod pathways, and thermoplastic half-round rods that insert into those grooves. The tray keeps the rods aligned and captured, and the rods become the bearing surface.

How is RIBS installed on existing supports?

The FRP tray is attached to the top of the beam or support steel using two-part epoxy, double-sided VHB tape, or mechanical fastening through the tray when required. The rods are then inserted into the tray grooves and the pipe is set down onto the rods—without drilling through the rods, which usually weakens their structural integrity.

Why use a tray instead of loose thermoplastic rods?

The tray prevents rods from rolling or walking, allows attachment without drilling through the rods, and lets you use multiple rods to spread pipe load. Sharing the load across multiple rods reduces point loading and helps minimize wear and coating damage at the support.