SmartPad System

- Home

- Non-Metallic Piping Products

- SmartPad System

Non-Metallic Products

Photo Gallery

Brochure

For more information about our product, download our brochure.

Let’s Start Work

Together

What is the SmartPad System?

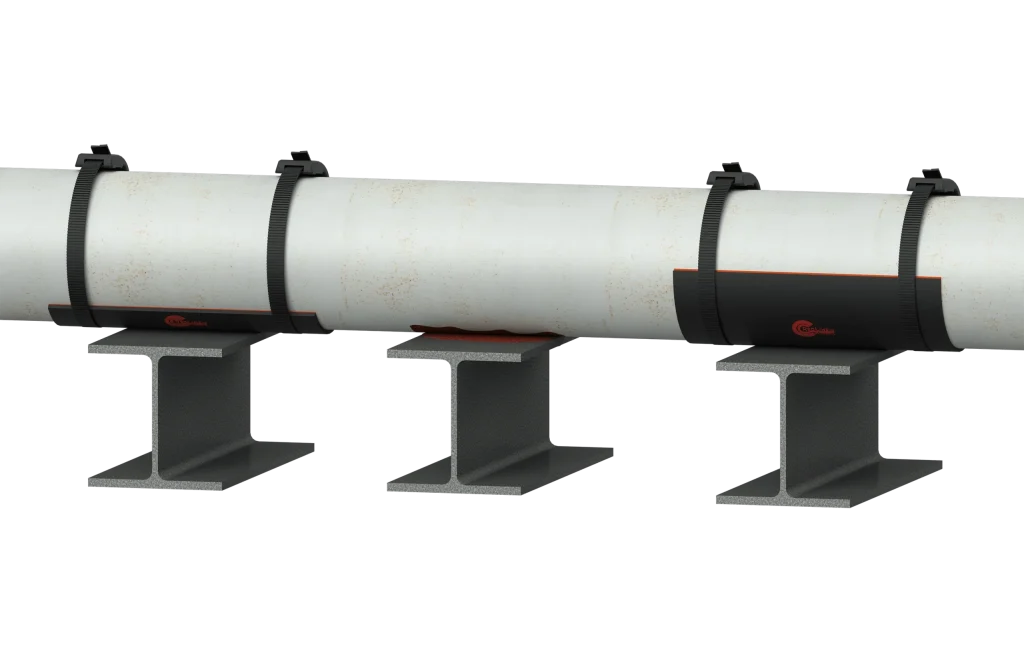

The RedLineIPS SmartPad System from Cogbill, patent-pending, is a pioneering fiber-reinforced plastic (FRP) Wear Pad System designed to protect above-ground piping systems from external corrosion at the pipe support points. The SmartPads neither require epoxy nor welding for installation, enabling swift installation, removal, and reinstallation in minutes. This drastically reduces installation, corrosion inspection, and maintenance costs, hence significantly reducing total cost of ownership.

This image is interactive. Click on any red marker for more information.

1 of 8 FRP Buckles 2 of 8 FRP Buckles 3 of 8 Hydroseal Gasket 4 of 8 FRP Wear Pad 5 of 8 FRP SmartBands 6 of 8 FRP SmartBands 7 of 8Manual SmartTool

8 of 8How the SmartPad System Works

The RedLineIPS SmartPads, constructed entirely from FRP material just like traditional composite wear pads, feature unique design enhancements and incorporate a Hydroseal watertight gasket, rated at a NEMA-4 watertight seal. The RedLineIPS SmartPads achieve the following key functions:

- Eliminate metal-to-metal contact, preventing the formation of galvanic corrosion.

- Safeguard the pipe's section that creates a crevice with the support structure, thereby eliminating crevice corrosion.

- The saddle shape of the SmartPads protects the pipe's paint coating from friction, preserving its corrosion-fighting capabilities.

- The use of easily installable and removable FRP straps enables visual corrosion inspection at a fraction of the cost compared to methods involving ultrasound, radiography, and similar techniques.

SmartPad System Components

Fiber-Reinforced Plastic (FRP) Exoskeleton

SmartBand and Buckles

Heavy-duty, non-corrosive, continuous-strand fiber-reinforced polymer straps securely fasten the SmartPads to a pipe, providing exceptional strength and retention force. Made to last and retain tension for 30 years, potentially longer. Allow the pads to be installed and removed in mere minutes, allowing quick pipe inspection.

SmartTool

Specifically designed for tightening the SmartBands to the pipe. Constructed from high-grade composite materials and metallic materials to generate sufficient force to compress the Hydroseal gasket. The ergonomic design ensures user convenience and efficient operation. Available in alternative variations for functionality.

SmartPad System Benefits

Quick SmartPad Installation Process

The challenge of corrosion under pipe supports (CUPS) poses a substantial financial burden on industries globally, costing billions of dollars each year. Various solutions have been introduced over the past few decades to combat this issue, each with its own effectiveness. In general, these solutions exhibit strengths and weaknesses, and the optimal choice may depend on various factors. The following is a comparison between some notable solutions and how they compare to the RedLineIPS SmartPad System. And for more in-depth discussion and comparison between all available solutions, visit our comparison page here.

RedLineIPS SmartPad System vs. Alternative Solutions

| Metallic Wear Pads | Metal Round Bar | Plastic Round Bar | Rubber / Plastic Liners | Epoxied-On FRP Wear Pads | SmartPad System | |

|---|---|---|---|---|---|---|

| Eliminates Crevice Corrosion? | Yes | Yes | Yes | Yes* | Yes | Yes |

| Eliminates Galvanic Corrosion? | No | No | Yes | Yes* | Yes | Yes |

| Prevents Metal-to-Metal Contact? | No | No | Yes | Yes* | Yes | Yes |

| Saddle Shape Cradles Pipe to Alleviate Stress? | Yes | No | No | No | Yes | Yes |

| Eliminates Point-Loaded Stress? | Yes | No | No | Yes | Yes | Yes |

| Strong Structural Resilency? | Yes | Yes | No | No | Yes | Yes |

| Works with Pipes Previously Treated for Corrosion? | Yes | Yes | Yes | Yes | No | Yes |

| Minimal Installation Training Needed? | No | No | Yes | No | No | Yes |

| Minimal Possibility of Faulty Installation? | No | No | No | No | No | Yes |

| Welding or Welding Permits Not Required? | No | No | Yes | Yes | Yes | Yes |

| Epoxy Not Required? | Yes | Yes | Yes | Yes | No | Yes |

| Eliminates Line Shutdown Requirement? | No | No | Yes | Yes | Yes | Yes |

| Eliminates Need for Paint Touchup? | No | No | No | No | Yes | Yes |

| Minimal Corrosion Inspection Cost? | No | Yes | Yes | No | No | Yes |

| Average Installation Time? (Minutes) | 60 | 30 | 5 | 5 | 15 | 2 |

| * Yes, for a limited time, until torn or shifts out of position | ||||||

SmartPad System Benefits

- Heavy-duty, all-composite material

- Eliminates metal-to-metal contact

- Prevents external corrosion in piping systems (CUPS)

- Epoxyless, installs in seconds

- Weldless, requiring no welding or line shutdown

- Installs on live lines

- Quick removal and reinstallation

- Allows visual inspections for external corrosion in seconds

- 100% install success rate

- Reusable: Cost-effective and green solution

- Wide range of gasket materials to suit specific applications

- Corrosive chemicals options available

- Dampens vibration and noise

- -60°F to 400°F (-51C to 204C) operating temperatures

RedLineIPS SmartPad System: Effective Solution for CUPS

Dive into the next era of piping support with the RedLineIPS SmartPad System, a groundbreaking leap in the domain of pipe supports. Imagined and crafted from the ground up, the SmartPad elevates the conventional FRP wear pads to an unprecedented level. Engineered for efficiency, our SmartPads are installed in mere minutes and can be swiftly removed to facilitate external corrosion inspections, then reinstalled just as quickly. This innovation eradicates the need for costly corrosion inspection methods like Ultrasonic Testing (UT), Radiographic Testing (RT), Electromagnetic Acoustic Transducer (EMAT), and Magnetic Flux Leakage (MFL). With a weld-less and epoxy-less design, pipe maintenance no longer necessitates paint touch-ups post-installation. The adoption of our system by industry giants such as Chevron, Formosa Plastics, and Nutrien speaks volumes about its effectiveness and reliability. For a deeper dive into the RedLineIPS SmartPad System, we invite you to visit our dedicated SmartPad System website.

FAQ's

Typical Queries and Information

What is the SmartPad System?

The SmartPad System is a patent-pending, all non-metallic pipe-support interface from Cogbill (sold under the RedLineIPS brand) designed to protect above-ground piping from external corrosion at support points. It installs without welding, drilling, or epoxy, and it’s built to be opened and re-secured quickly for visual corrosion inspection.

How does the SmartPad System reduce CUPS risk at pipe supports?

It targets the common “CUPS recipe” (corrosion under pipr supports) at support locations: coating damage from micro-motion, moisture retention in the crevice, and metal-to-metal continuity. The contoured FRP saddle protects the coating and spreads load, the sealed gasket helps block moisture from the pipe-to-pad interface, and the non-metallic load path helps break galvanic continuity at the contact region.

What components make up a SmartPad assembly?

The system is built around four core elements: an FRP saddle (exoskeleton), a bonded closed-cell Hydroseal gasket, non-metallic SmartBands with buckles, and a dedicated tensioning tool (SmartTool) to apply consistent band preload, with built-in cutter to trim excess banding material.

What does the Hydroseal gasket actually do?

The Hydroseal is a closed-cell gasket bonded to the saddle that compresses against the pipe to establish a watertight seal at the interface (marketed as a NEMA-4-rated seal when compressed). The goal is to keep moisture and salts from living in the tight crevice where CUPS typically starts and hides.

Does SmartPad require shutdowns or hot work to install?

No. It’s intended for cold installation on live lines—no hot-work permits, no weld repairs, and no epoxy use or cure time—so crews can install quickly while avoiding burned coatings and permit-driven delays.

How fast is installation, and what does inspection look like later?

Field installs are designed to be quick (often minutes per support). For inspection, crews can release the bands, lift/open the interface to visually check the hotspot directly, then re-band and re-seal—without destroying the support or cutting anything off the pipe.

What environments and temperatures is the SmartPad System intended for?

It’s positioned for onshore plants, offshore platforms, and FPSOs—especially where salt air, humidity, splash/washdown, and tight pipe racks make CUPS more aggressive and harder to inspect. The published service window is approximately −60°F to 400°F (−51°C to 204°C).

How is SmartPad different from traditional FRP wear pads or thermoplastic rods?

Traditional wear pads/rods can reduce metal-to-metal contact, but they often rely on adhesives or create interfaces that are harder to “open up” for direct visual inspection. SmartPad adds a gasketed, reopenable interface secured by non-metallic banding so inspection and re-sealing can be done quickly at the same support point.