Wear Pads & Flat Pads

- Home

- Non-Metallic Piping Products

- Wear Pads & Flat Pads

Non-Metallic Products

Photo Gallery

Brochure

For more information about our product, download our brochure.

Let’s Start Work

Together

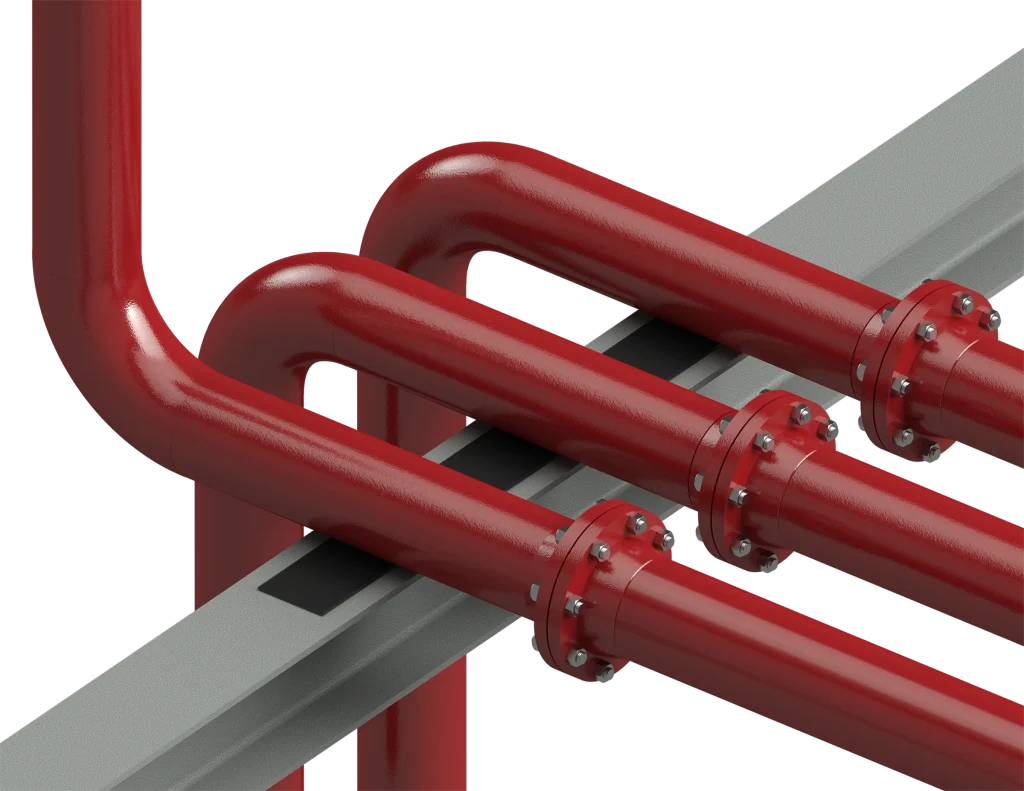

What are RedLineIPS FRP Wear Pads & Flat Pads?

RedLineIPS FRP Wear Pads

Purpose of RedLineIPS FRP Pads

- Protection of Paint Coating: The RedLineIPS FRP Wear Pads cradle the pipe’s underside, preserving its paint coating and allowing it to protect the pipe from corrosion throughout its life cycle.

- Prevention of Galvanic Corrosion: These composite, non-conductive FRP wear pads isolates the pipes from their supports, preventing metal-to-metal contact and eliminating the risk of galvanic corrosion.

- Prevention of Crevice Corrosion: Our pads protect against crevice corrosion by shielding the pipe at the support points, effectively preventing corrosion from forming.

- Moisture Prevention: Applying either VHB double-sided tape or a perimeter bead of epoxy around the FRP wear pad edges prevents moisture from becoming trapped, inhibiting conditions that promote corrosion.

FRP Pads Installation Methods

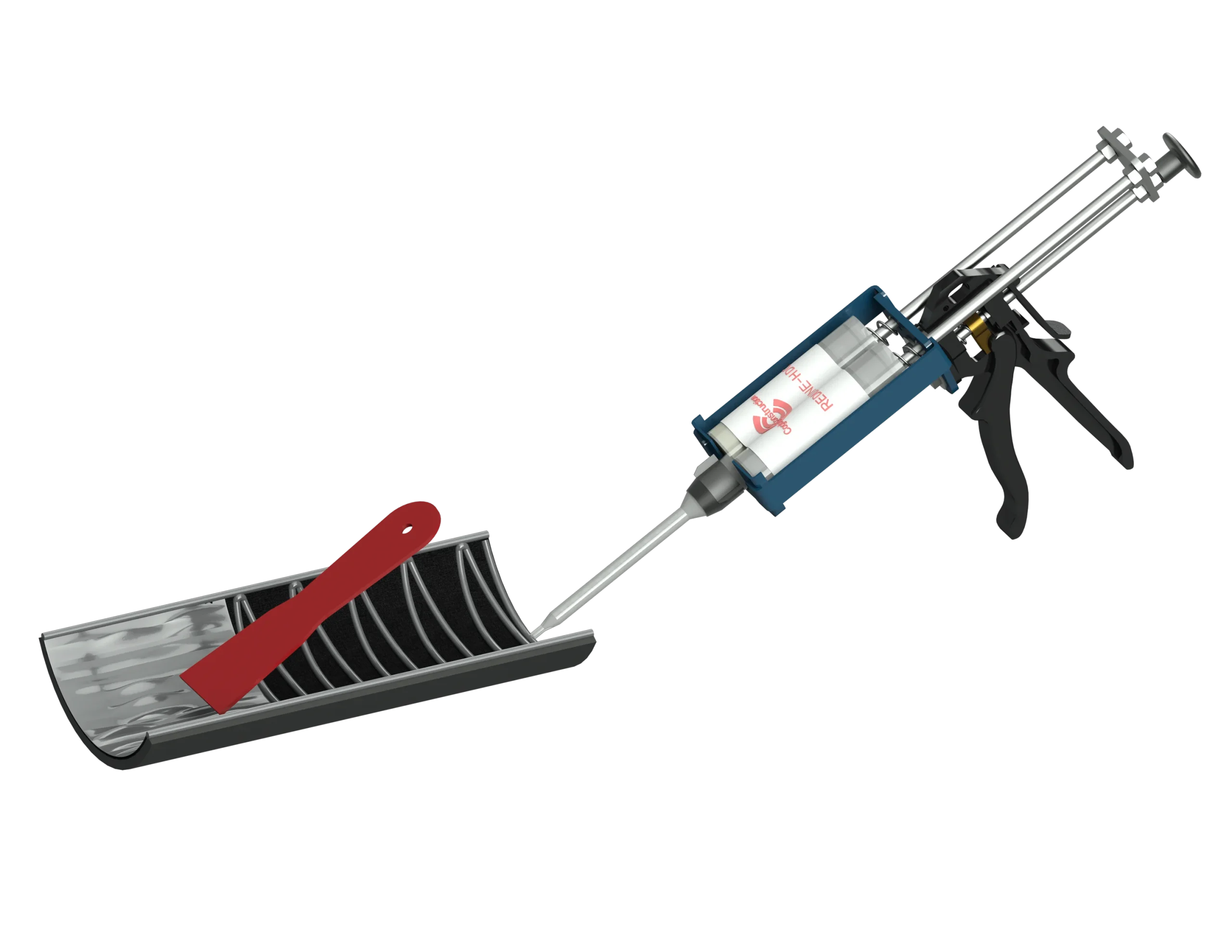

RedLineIPS Wear Pads with Two-Part Epoxy

RedLineIPS FRP Wear Pads, when used with our two-part epoxy, deliver high shear and compressive strength, as verified through independent lab testing*. Each pad also features a textured interior profile finish covered by a protective film to enhance adhesion, and prove authenticity.

*Verified by independent lab testing, contact us for details

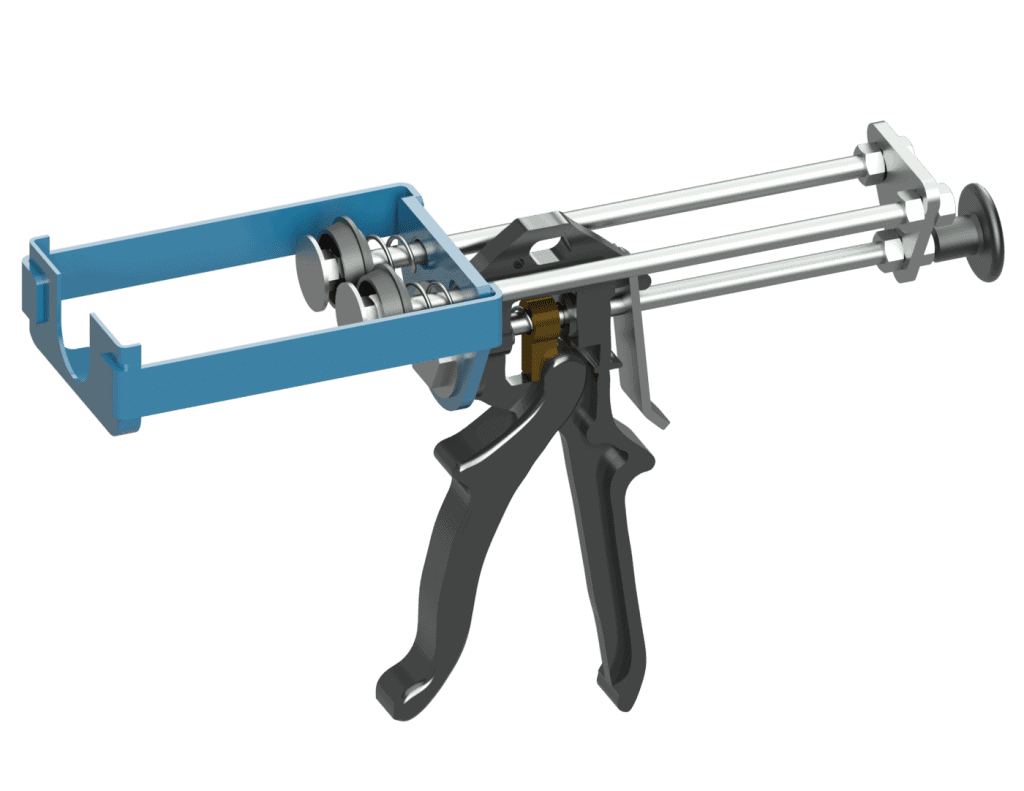

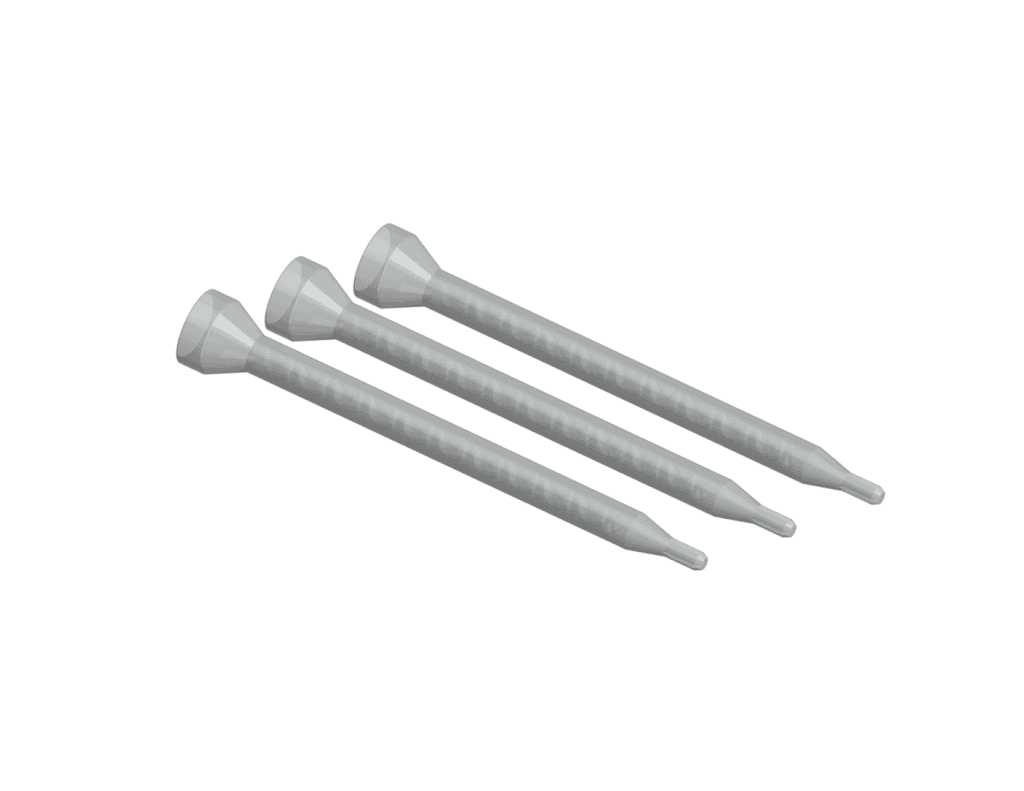

RedLineIPS offers a comprehensive Composite Wear Pad System that includes: Composite Wear Pad, Two-Part Epoxy, Epoxy Applicator Gun, Applicator Mixing Nozzle, and preparation and cleaning solutions. Additionally, full installation and training guides and services are provided to ensure proper application and optimal performance.

RedLineIPS Wear Pad System Benefits

Outstanding Corrosion Protection

Fire Retardant

Accommodate any pipe size

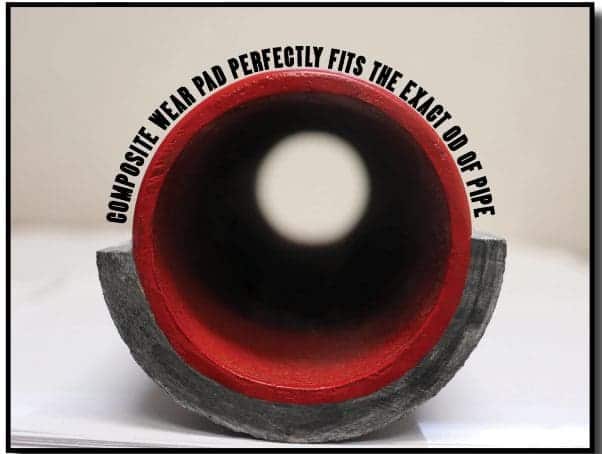

Manufacturing process precisely matches pipe’s outside diameter

Welding and hot work permits not required

Install on live lines, system shutdowns not required

Maintenance-free performance

Specifications

Composition: RedLineIPS Composite

Max Compressive Strength: 90,000 lbs.

Temperature Range: -320°F to +400°F

Installation: RedLineIPS Epoxy System

Required Accessories: Epoxy, static mixing nozzle, dual epoxy applicator

Custom Manufacturing: Available in any thickness, coverage angle and length

Wear Pad System & Installation

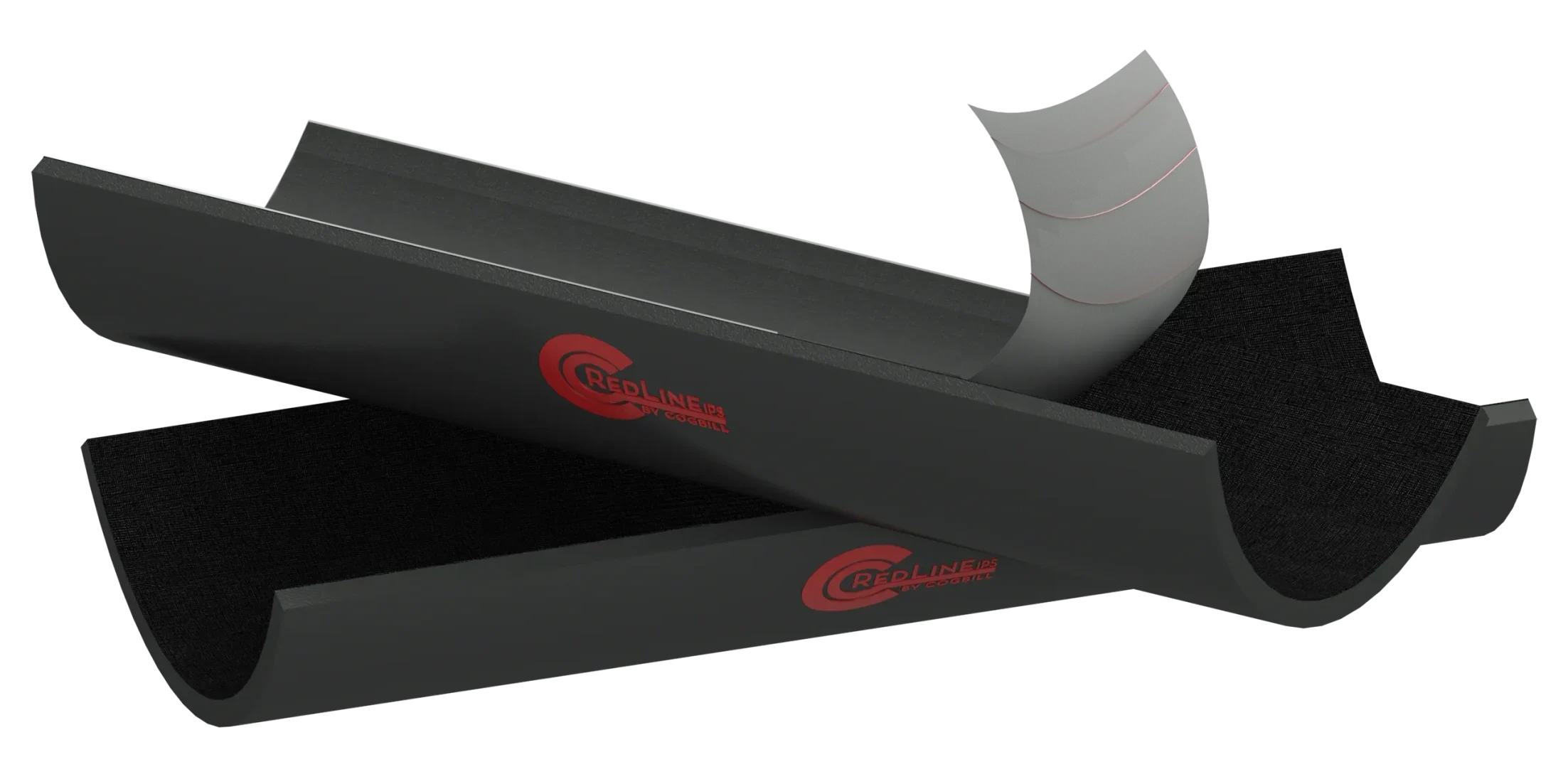

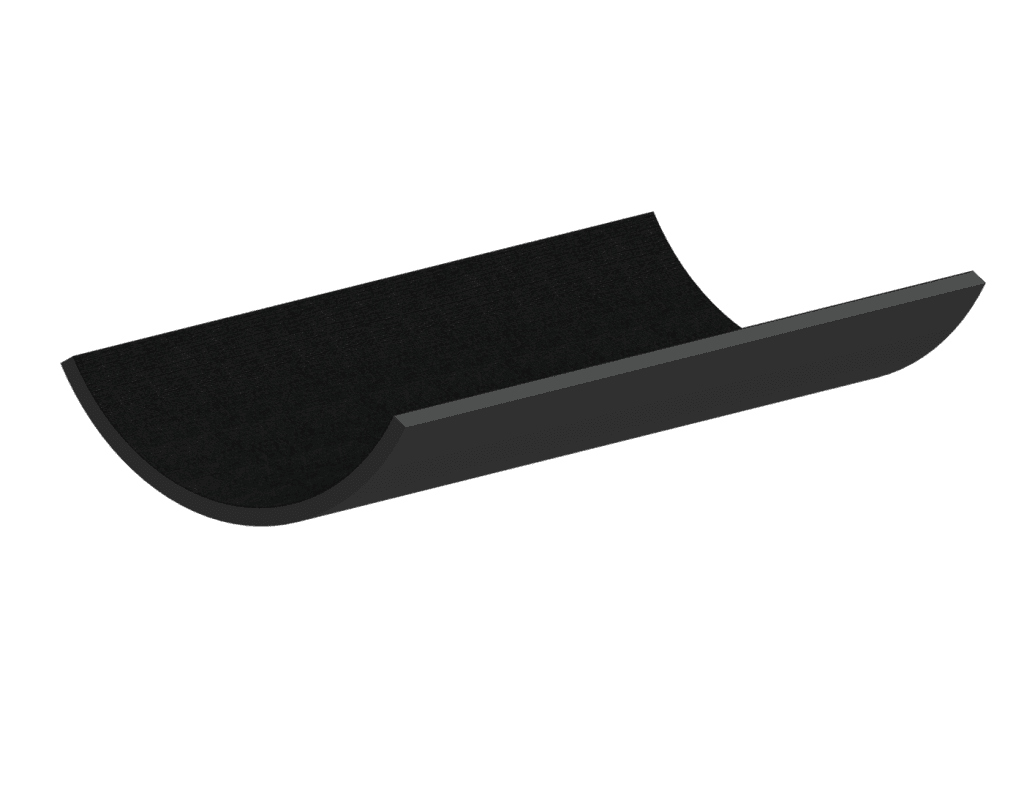

Composite Wear Pad

Textured Profile Finish On Inner Surface, Perfect For Adhesion. Custom Lengths, Thicknesses, And Degrees Of Coverage

Two-Part Epoxy

High Shear & Peel Strength. Resistant To Shock, Extreme Temperatures, Chemicals & Crystallization

Applicator Gun

Removes Human Error & Delivers Consistent & Reliable Application

Static Mixer

16 Internal Mixing Elements Efficiently Mix Two-part Epoxy In A Perfect 1:1 Ratio

Emery Cloth

Creates A Roughened Profile For Better Epoxy Adherence

Contact Cleaner

Ensures A Clean Surface For An Effective & Long Lasting Bond

RedLineIPS Wear Pads with VHB Tape

The application of 3M’s VHB double-sided tape in installing FRP components is particularly advantageous in settings where corrosion resistance and durability are paramount.

The tape’s ability to distribute stress uniformly across the bond area enhances the protective capabilities of FRP wear pads and flat plates, preventing weak points that could lead to wear or corrosion. Moreover, this method eliminates the need for drilling or welding, preserving the integrity of the protected surfaces and reducing the risk of introducing corrosion points. The ease of use and clean, aesthetically pleasing installation make 3M VHB tape an ideal choice for securing FRP wear pads and flat plates in various industrial applications, from piping systems in chemical plants to infrastructure projects where long-term reliability is critical.

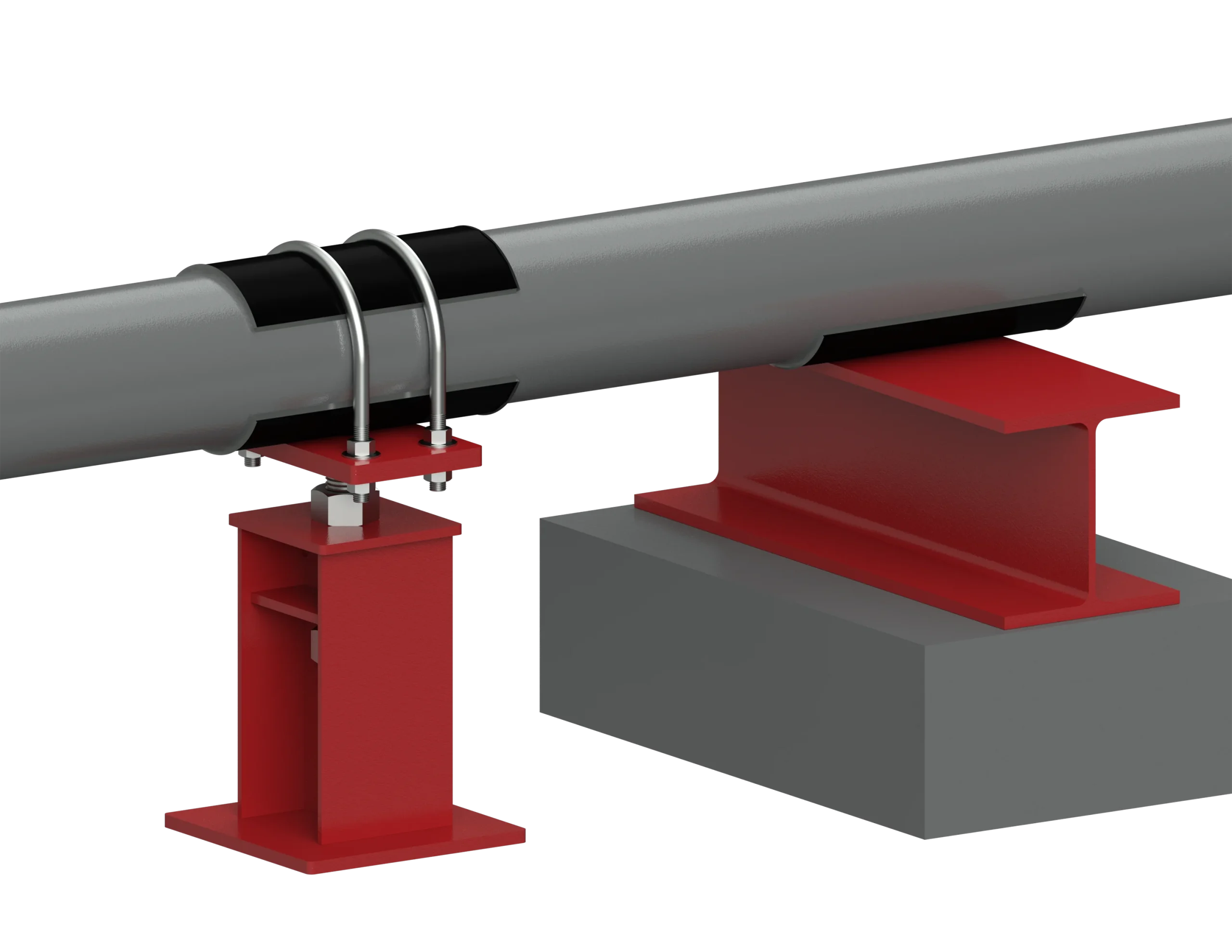

FRP Flat Pads

Cogbill’s RedLineIPS FRP Flat Pads

Cogbill’s RedLineIPS FRP Flat Pads can serve as a cost-effective alternative to FRP wear pads by acting as separators between pipes and their supporting structures. These pads can be affixed to supporting beams using either a resilient two-part epoxy or double-sided 3M VHB tape for quick installation.

Expertise in FRP Materials

Cogbill boasts extensive expertise in FRP (Fiber Reinforced Polymer) materials, positioning us as a leading authority in the manufacture and supply of various FRP products, especially those intended to protect above-ground piping from corrosion at the pipe support points. Leveraging our in-depth knowledge and years of experience, we deliver solutions that enhance the durability and longevity of industrial piping systems. If you’re grappling with corrosion issues or seeking reliable pipe support solutions, Cogbill is ready to assist with its comprehensive line of RedLineIPS heavy-duty FRP products. Contact us today to explore how our FRP products can address your specific needs and transform the way you manage corrosion.

FAQ's

Typical Queries and Information

What are RedLineIPS FRP wear pads and flat pads used for?

They are non-metallic separators used at pipe support points to reduce metal-to-metal contact, protect coatings, and lower the risk of external corrosion at pipe supports (CUPS). Wear pads cradle the pipe; flat pads sit on the support surface to provide a composite bearing interface.

What is the difference between an FRP wear pad and an FRP flat pad?

An FRP wear pad is saddle-shaped and rolled to match a specific pipe OD so the pad is bonded to the pipe and carries on the support. An FRP flat pad is a plate-style separator bonded to the beam or support steel to create a non-metallic bearing surface where a flat interface is acceptable.

How do FRP wear pads and flat pads help reduce CUPS risk?

They provide a dielectric barrier between the pipe and steel, preventing galvanic corrosion, and help protect the pipe’s coating from abrasion at the contact point. When installed correctly—especially with good surface prep and sealed edges where specified—they reduce crevice conditions and moisture retention that commonly drive CUPS at supports.

How are FRP wear pads installed?

Wear pads are typically bonded directly to the pipe using a two-part epoxy or high-bond double-sided tape systems (VHB) where permitted by the project. Epoxy installations often include an edge seal to help keep moisture out. Installation quality depends heavily on surface preparation, correct adhesive use, and proper cure/handling.

How are FRP flat pads installed?

Flat pads are commonly bonded to structural steel using epoxy or high-bond double-sided tape systems (VHB), then used as the bearing interface between the pipe (or shoe) and the support. They can be supplied in standard sizes or cut to match the required bearing area and thickness.

Can wear pads and flat pads be supplied as a complete installation kit?

Yes. Cogbill can supply the pads along with installation consumables and accessories—such as epoxy, mixing nozzles, surface-prep materials, and basic installation guidance—so field crews have what they need for consistent bonding.

When should I choose tape vs. epoxy for installation?

Tape is often chosen when speed and simplicity are critical and the project allows it, while epoxy is typically preferred when you want the most robust bonded interface and the ability to seal the perimeter for moisture control in demanding environments.