Weldless pipe shoes, or non-welded pipe shoes, represent an innovative solution in industrial piping systems, addressing several key issues that have long plagued the industry, such as corrosion under pipe supports (CUPS), ease of installation, and long-term system reliability. Traditional pipe supports often require welding, which introduces potential points of failure through heat-affected zones and increases the risk of corrosion, particularly in challenging environments like offshore facilities or chemical processing plants. Line shutdowns and welding permits may also be required, which affects productivity and adds to cost. Weldless pipe shoes eliminate these risks by using clamping mechanisms such as pipe clamps, U-bolts, straps, or other fasteners, providing robust, secure support without the need for welding

What Are Non-Welded Pipe Shoes?

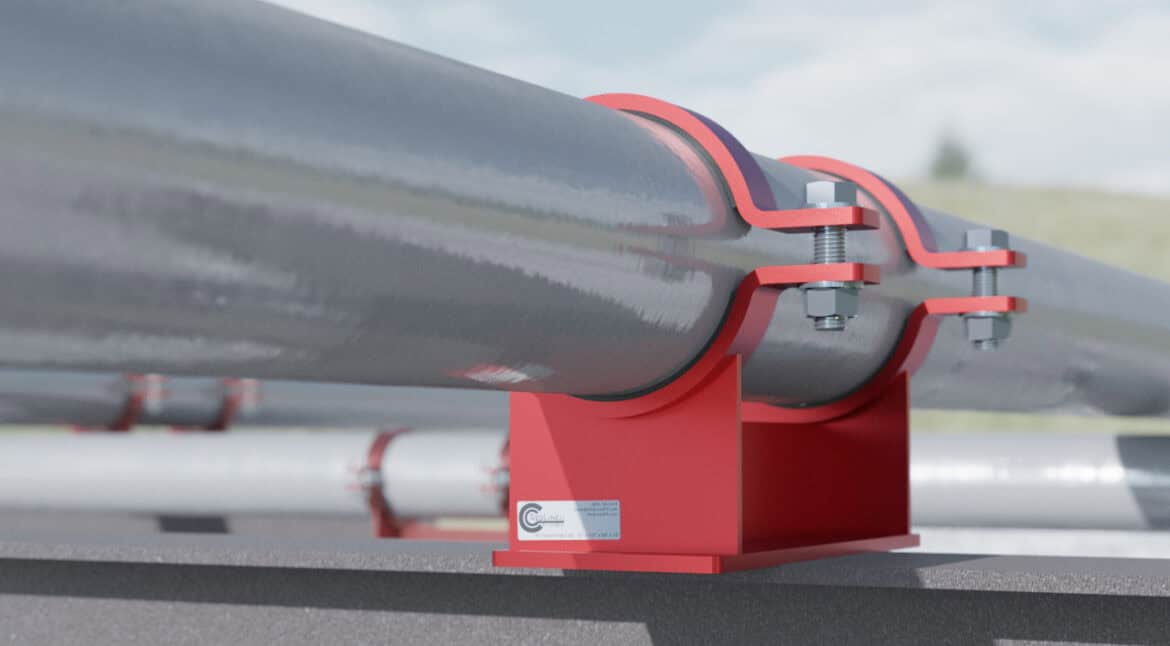

Non-welded, or weldless, pipe shoes are a type of pipe support that attaches to pipes using clamps, U-bolts, or mechanical fasteners instead of welding. This design allows for a secure, reliable connection without introducing the issues that welding can cause, such as heat-affected zones, which can weaken the pipe’s material or create points vulnerable to corrosion. The key advantage of weldless pipe shoes is their ability to maintain the structural integrity of the pipe while offering the same (or better) levels of support as traditional welded shoes.

Components of a Weldless Pipe Shoe

- Base Plate: The base of the pipe shoe is typically a flat or curved metal plate designed to distribute the load over a wider area, reducing stress on both the pipe and the underlying structure. In weldless designs, this base plate is usually bolted or fastened securely to the support structure. A slide plate may also be incorporated to allow controlled, smooth movement, protecting the piping system from stresses caused by factors such as thermal expansion or contraction. This is particularly useful in systems where temperature fluctuations are expected.

- Clamp Mechanism: Rather than welding the pipe to the shoe, a clamping system—typically consisting of U-bolts, clamps, or straps—securely holds the pipe in place. These clamps can be tightened around the pipe, providing a firm grip without damaging the surface.

- Isolation Liners (Optional): Many weldless pipe shoes, including those offered by RedLineIPS, can be fitted with non-metallic liners made of materials such as neoprene or PTFE to reduce friction, prevent metal-to-metal contact, and further minimize the risk of corrosion.

- Bolts and Fasteners: The entire assembly is often held together by bolts and fasteners, which allow for easy installation and adjustment. This is a significant benefit over welded shoes, which once installed, cannot be easily modified.

Types of Weldless Pipe Shoes

- Clamp-On Pipe Shoes: These are one of the most common types of weldless pipe shoes, using a clamp system to attach directly to the pipe. The shoe base can be bolted to structural supports, and the pipe is held in place by adjustable clamps.

- U-Bolt Pipe Shoes: These utilize U-bolts to fasten the pipe to the shoe. U-bolt shoes are particularly useful in systems where vibration is a concern, as the bolts can be tightened securely to prevent movement.

- Saddle-Type Shoes: These support the pipe like a saddle, using clamps or straps to secure the pipe to the support structure. They are typically used for larger pipes where additional support is required across a larger surface area.

Why Choose Weldless Pipe Shoes?

1- Elimination of Corrosion Under Pipe Supports (CUPS)

One of the most significant advantages of weldless pipe shoes is the reduction or elimination of corrosion under pipe supports (CUPS). In traditional systems, welding creates heat-affected zones that can weaken the metal and create points where corrosion is more likely to occur, especially in environments exposed to moisture, chemicals, or saltwater. CUPS occurs when moisture or corrosive agents accumulate at the pipe support points, leading to rapid degradation of the pipe. Weldless pipe shoes mitigate this by:

- Avoiding Welding: No heat is applied to the pipe, meaning no heat-affected zones that are more prone to corrosion.

- Using Liners: RedLineIPS weldless pipe shoes can be equipped with corrosion-resistant liners that separate the pipe from the shoe, preventing metal-to-metal contact. This reduces the risk of galvanic corrosion, particularly in harsh environments like offshore platforms.

- Improved Drainage: Eccentric or saddle designs can be used to prevent moisture accumulation at the bottom of the pipe, further reducing the risk of corrosion.

2- Ease of Installation and Maintenance

Another major advantage of weldless pipe shoes is their ease of installation. Traditional welded shoes require specialized labor, careful preparation, and downtime for cooling and inspection. Non-welded designs, by contrast, can be installed quickly using basic tools.

- Fast Installation: Weldless pipe shoes are typically installed using mechanical fasteners, clamps, or U-bolts. This makes the installation process faster, reducing downtime and labor costs.

- Adjustability: Many weldless pipe shoes, including adjustable-height models from RedLineIPS, allow for height adjustment after installation. This is especially useful in complex systems where precise alignment is needed.

- Reduced Maintenance: Since there is no welding involved, weldless pipe shoes don’t require regular inspection of weld seams, saving time and reducing maintenance costs. Additionally, their modular nature allows for easy replacement of components without disturbing the entire system.

3- Flexibility in Design and Application

Non-welded pipe shoes offer more flexibility in terms of design and application than traditional welded supports. They can be used in a wide range of environments and are adaptable to various piping configurations.

- Modular Systems: Weldless designs allow for modularity, meaning components can be easily replaced or upgraded as needed. If a system needs to be retrofitted or reconfigured, weldless pipe shoes offer a significant advantage since they can be easily removed or adjusted.

- Custom Solutions: RedLineIPS offers custom fabrication of weldless pipe shoes, allowing for solutions tailored to specific industrial needs. This includes special linings, adjustable designs, and shoes made from materials suited to corrosive or high-temperature environments.

- Non-Metallic Applications: Weldless pipe shoes can also be adapted for non-metallic piping systems, such as those made from FRP (Fiber Reinforced Plastic). Non-metallic pipe shoes require different clamping mechanisms and materials, and RedLineIPS provides solutions for these systems, offering shoes with non-corrosive liners and fastening mechanisms that don’t damage the pipe.

4- Thermal Expansion and Vibration Control

Managing thermal expansion is crucial in systems exposed to temperature fluctuations. Welded pipe shoes can sometimes cause stress concentration at the welded points, particularly if the system undergoes significant thermal expansion. Weldless pipe shoes, on the other hand, distribute stress more evenly and allow for better management of thermal movement.

- Vibration Control: In systems where vibration is a concern, such as pipelines near compressors or turbines, weldless pipe shoes with U-bolts or other clamping systems offer a more secure grip, reducing vibration-induced wear and tear. Additionally, RedLineIPS pipe shoes can be equipped with vibration-dampening liners, such as neoprene or PTFE, to further mitigate the effects of vibration.

- Thermal Expansion: Adjustable weldless pipe shoes can accommodate expansion and contraction of the piping system by allowing movement without exerting undue stress on the pipe or the supports. This is especially important in high-temperature systems such as steam lines or process piping.

5- Material Selection and Durability

Weldless pipe shoes must be constructed from materials that are compatible with the pipe and the environment in which they are installed. RedLineIPS offers a range of material options to ensure that weldless pipe shoes perform optimally in various industrial environments.

- Carbon Steel: Ideal for high-strength, high-pressure systems, carbon steel weldless shoes provide durability and long-term reliability. They are often used in oil and gas pipelines, power plants, and other heavy industrial applications.

- Stainless Steel: For environments that are highly corrosive or where hygiene is critical (e.g., food processing, pharmaceuticals), stainless steel weldless shoes provide excellent corrosion resistance and longevity.

- FRP (Fiber Reinforced Plastic): FRP weldless pipe shoes are designed for non-metallic piping systems and offer superior corrosion resistance, making them ideal for water treatment plants, chemical processing facilities, and other corrosive environments.

Applications of Non-Welded Pipe Shoes

- Offshore Platforms Challenge: Corrosive saltwater environments are notorious for causing rapid deterioration of welded joints. Solution: Weldless pipe shoes prevent corrosion under pipe supports and offer quick installation, which is crucial for minimizing downtime during offshore operations.

- Chemical Processing Plants Challenge: Chemical processing plants often deal with aggressive, corrosive substances that can degrade pipe supports. Solution: Weldless pipe shoes with corrosion-resistant liners or made from stainless steel or FRP are ideal for handling these environments.

- Power Generation Challenge: Power plants require systems that can handle high temperatures and vibrations from heavy equipment. Solution: RedLineIPS weldless pipe shoes with vibration-dampening features and thermal expansion control provide the stability and durability needed for such applications.

- Food and Beverage Processing Challenge: Hygiene and corrosion resistance are critical in food and beverage production. Solution: Stainless steel weldless pipe shoes eliminate the risk of contamination while providing long-term corrosion resistance in washdown environments.