Pipe Strainers

- Home

- Metallic Piping Accessories

- Pipe Strainers

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

What is a Pipe Strainer?

Types of RedLineIPS Piping Strainers

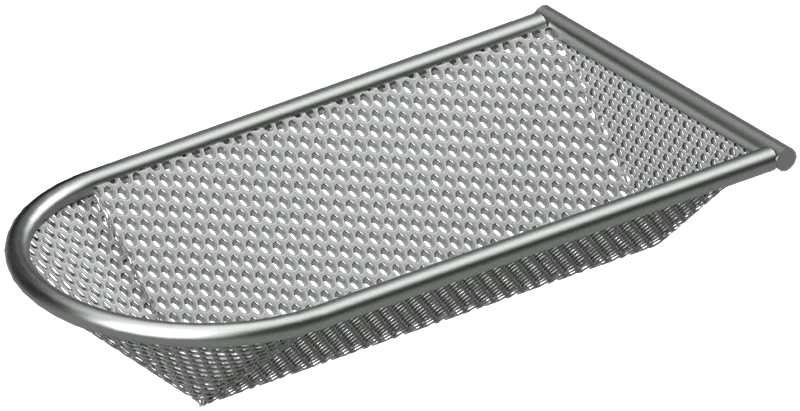

RedLineIPS Basket Strainers

- Application: Ideal for larger particle applications.

- Design: Features a removable basket for easy maintenance.

- Technical Details: Customizable perforations or mesh size based on particle size requirements.

- Purpose: Suitable for systems where periodic cleaning is feasible.

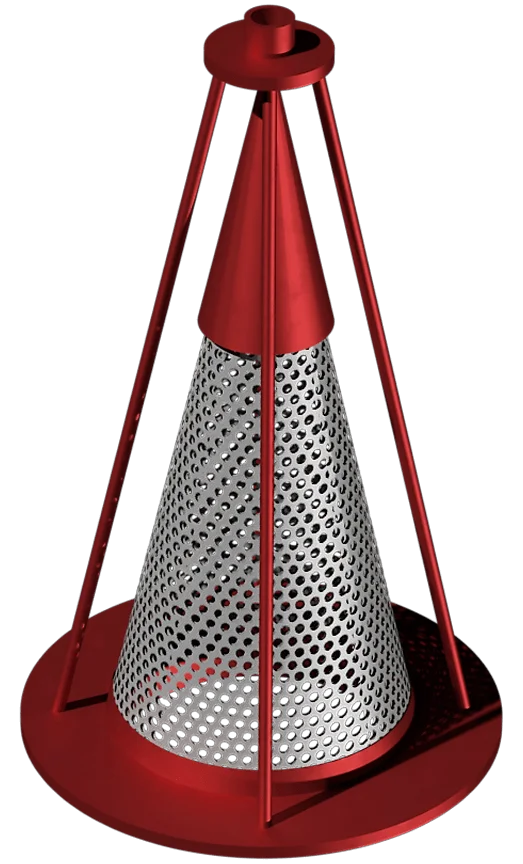

RedLineIPS Cone Strainers (Witch’s Hat)

- Application: Well-suited for processes with varying particle sizes.

- Design: Conical shape facilitates effective removal of particles.

- Technical Details: Large filtration area, efficient for fluctuating particle sizes.

- Purpose: Excels in situations where fluid viscosity may vary.

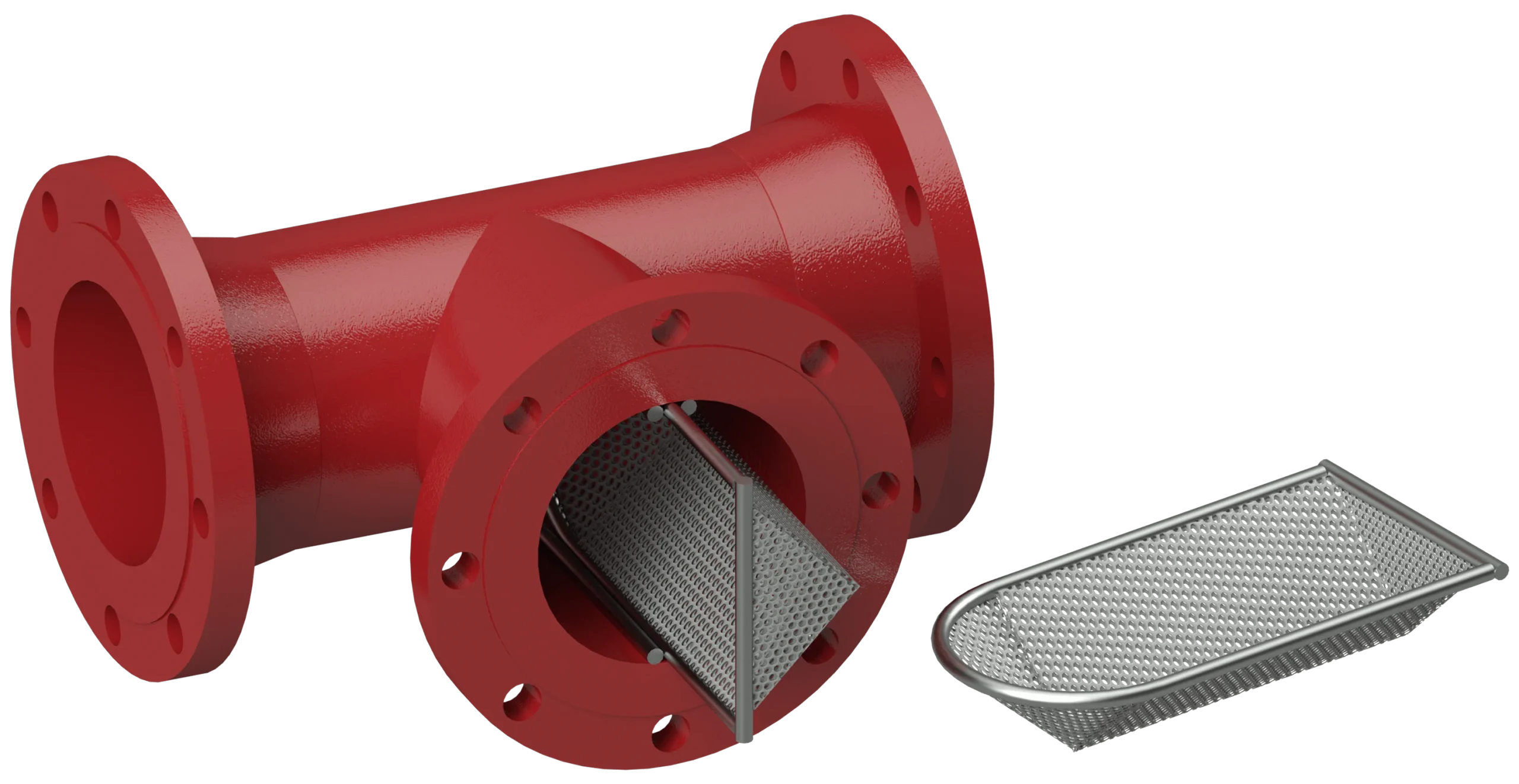

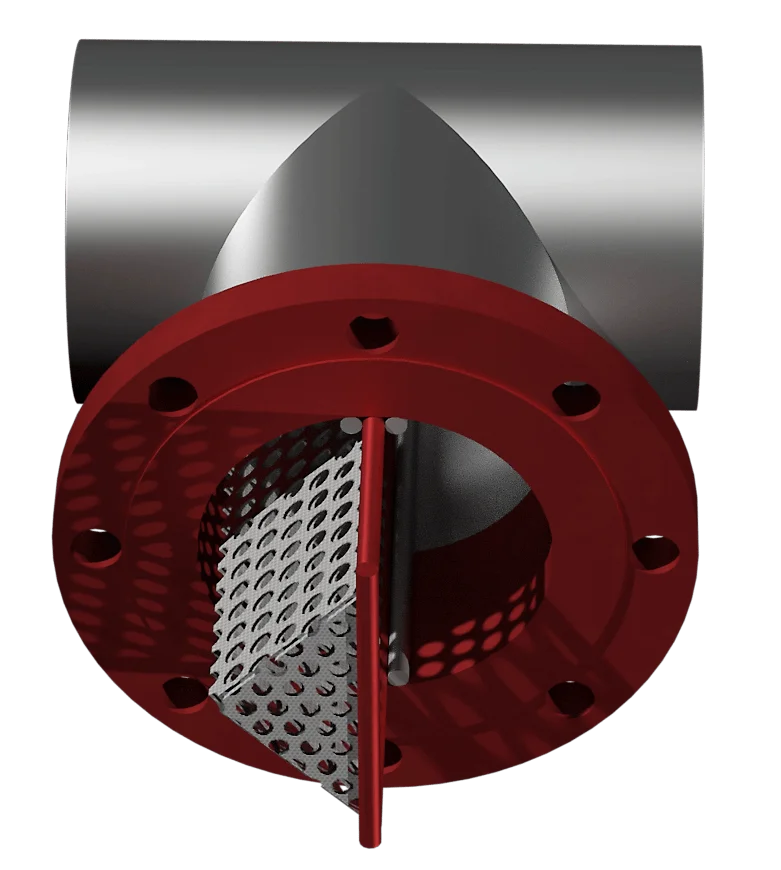

RedLineIPS Tee Strainers

- Application: Suited for high-flow applications where efficiency is crucial.

- Design: Fit in pipe Tees, hence the name, and captures particles effectively.

- Technical Details: Minimal impact on fluid flow, suitable for large-diameter pipes.

- Purpose: Effective in applications where compact design and minimal pressure drop are essential.

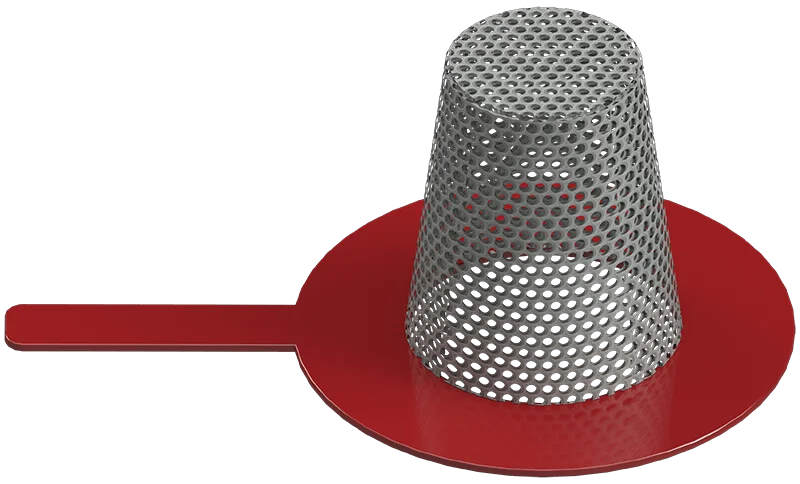

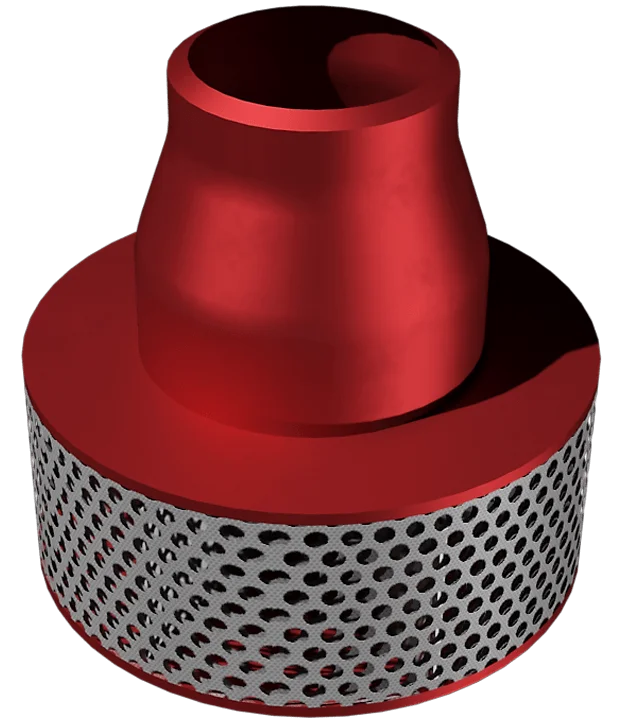

RedLineIPS Sump Suction Strainers

- Application: Specifically designed for pump applications.

- Design: Tailored for pump protection in fluid-intensive processes.

- Technical Details: Features a suction pipe extending into the sump, preventing large debris from entering the pump.

- Purpose: Crucial for protecting pumps from damage caused by large particles.

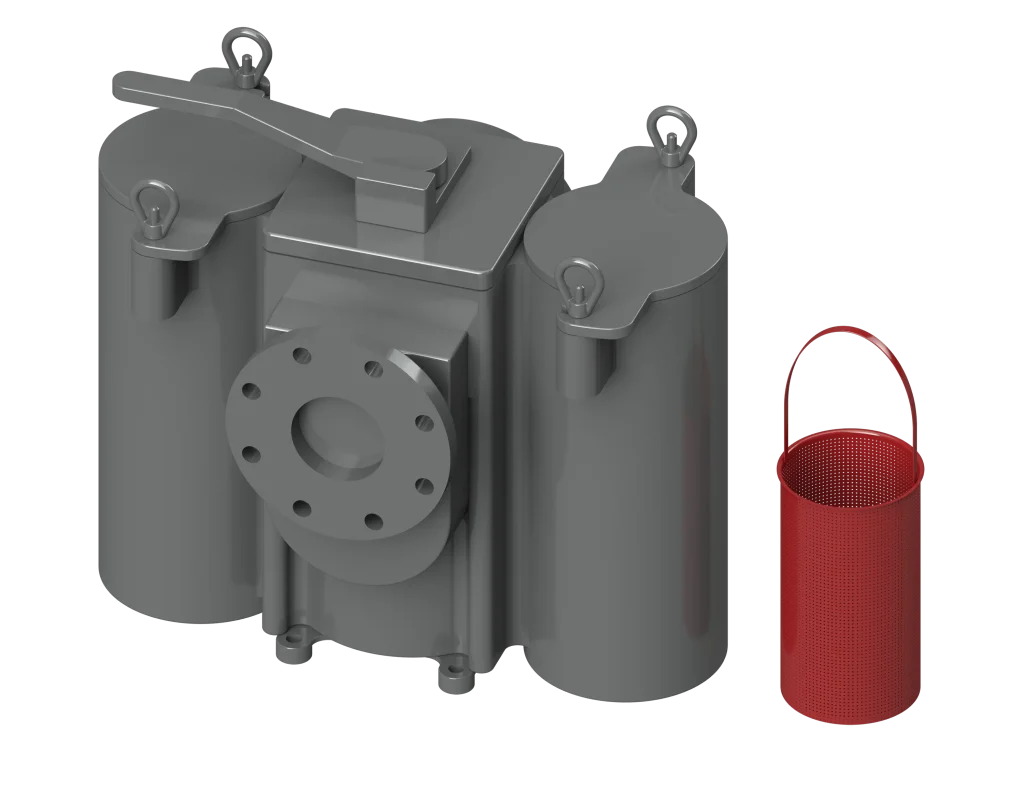

RedLineIPS Duplex Strainers

- Application: Offers continuous filtration without flow interruption.

- Design: Dual strainer baskets for seamless switching during maintenance.

- Technical Details: Two parallel strainer baskets for continuous filtration during maintenance.

- Purpose: Employed in processes where uninterrupted fluid flow is critical.

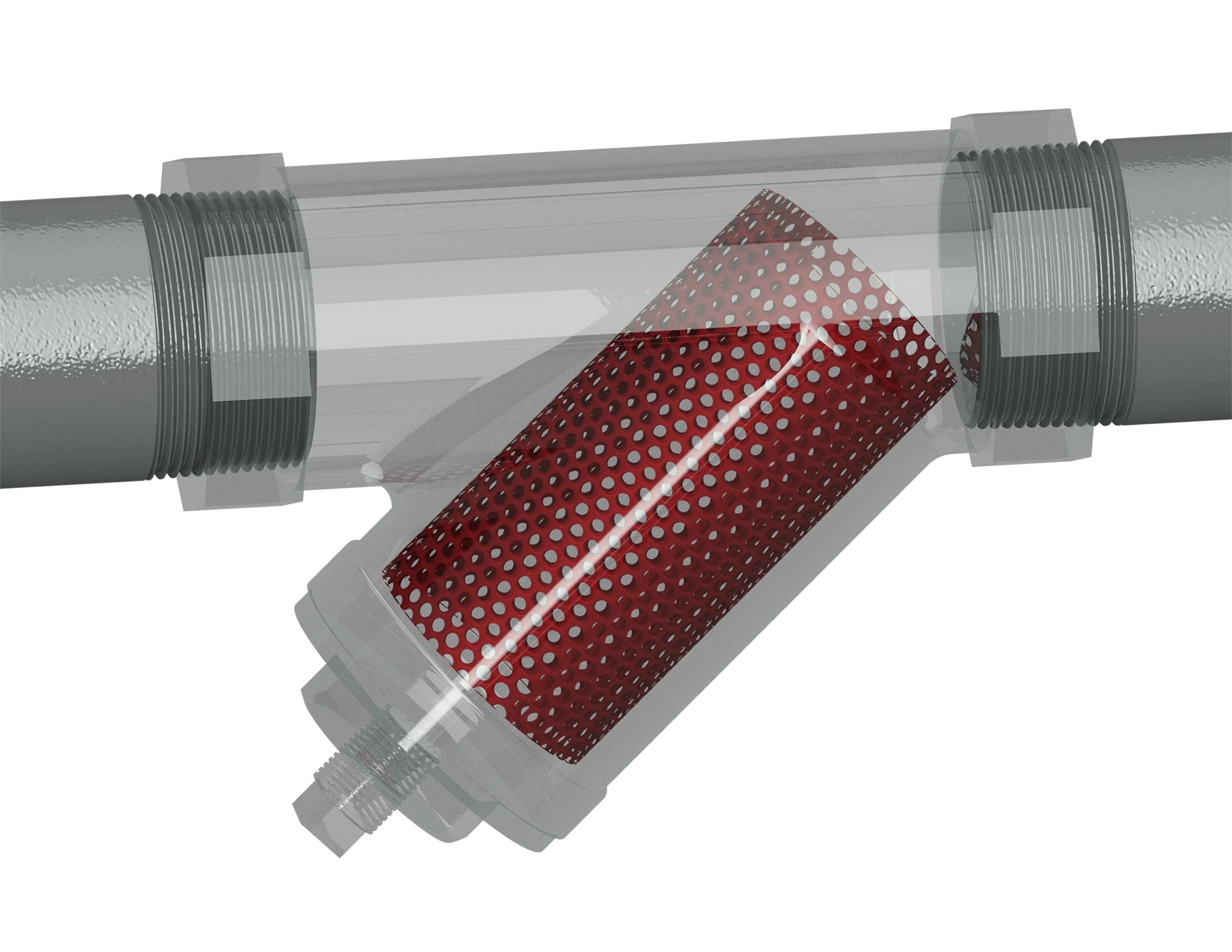

RedLineIPS Y-Type Strainers

Y-type strainers find their place in high-pressure pipelines, where the risk of damage from unwanted particles surpasses 6000 PSI. The choice between horizontal and vertical installation adds a layer of adaptability, aligning with the specific needs of diverse applications. While excelling in the filtration of small granules, regular maintenance becomes paramount, underscoring the importance of a cleaning regimen to prevent blockages and uphold peak performance. In essence, the Y-type strainer emerges not just as a component in a piping system but as a vital guardian, contributing to sustained efficiency and longevity of downstream equipment.

- Application: Well-suited for applications with smaller-sized particles.

- Design: Resembles the letter "Y" and effectively captures particles.

- Technical Details: Compact design, often used in applications where space is limited.

- Purpose: Effective in applications where the removal of smaller-sized particles is a primary concern.

Materials for Diverse Requirements

Properties: Resistant to corrosion, ideal for corrosive fluid applications.

Application: Commonly used in chemical and offshore applications.

Properties: Robust and cost-effective, suitable for general-purpose applications.

Application: Versatile, finding applications in various industrial processes.

Properties: Corrosion-resistant, often used in marine and offshore settings.

Application: Employed in marine and offshore applications due to resistance to corrosion in saltwater environments.

Properties: Lightweight and corrosion-resistant, cost-effective for various applications.

Application: Used where weight is a consideration, and resistance to corrosion is essential.

| Strainer Type | Design | Application | Pressure Range | Filtration Area | Maintenance | Pros | Cons |

|---|---|---|---|---|---|---|---|

| Y-Type | Y-shaped | High-pressure systems (>6000 PSI) | >6000 PSI | Moderate | Regular cleaning required | Efficient removal of small particles, Suitable for liquid filtration | Not ideal for significant dirt or particle loads, Frequent cleaning needed |

| Basket | Basket-shaped | Larger-sized particle removal | Up to 1500 PSI | Larger straining area | Frequent cleaning, parallel pipe installation | Efficient for larger particles, Less frequent cleaning | Lower pressure capacity |

| Cone | Conical-shaped | High-level filtration | Varies | Large filtration area | Moderate | Effective for high-level filtration, Reduced cleaning frequency | Limited to specific applications |

| Sump Suction | Specialized for industrial piping systems | Industrial | Varies | Varies | Moderate | Specifically designed for industrial systems | Limited versatility outside industrial settings |

| Tee | T-shaped | Low-flow applications | Low pressure | Moderate | Frequent cleaning needed | Compact size, Suitable for basic filtration in tight spaces | Not ideal for high debris applications, Requires frequent maintenance |

| Duplex | Dual-baskets | Higher-flow applications | Up to 1500 PSI | Larger straining area | Continuous operation during maintenance | Continuous operation, Suitable for higher flow rates | Regular maintenance crucial, Potential for clogging if neglected |

Why Choose RedLineIPS Pipe Strainers?

RedLineIPS pipe strainers are designed to meet the rigorous demands of industrial applications, ensuring your systems remain efficient and protected. Proudly made in the U.S.A., our strainers are custom-built to your specifications and shipped nationwide. For more information about our durable and reliable pipe strainers, contact us today.

FAQ's

Typical Queries and Information

What does a pipe strainer do in an industrial piping system?

A pipe strainer removes solid particles like rust, sand, scale, and debris from the flow stream before they reach pumps, valves, meters, and heat exchangers. This helps prevent equipment damage, unplanned downtime, and loss of efficiency.

What types of pipe strainers are available from Cogbill under the RedLineIPS brand?

Cogbill manufactures several common strainer configurations under the RedLineIPS brand, including basket strainers, cone (witch’s hat) strainers, tee strainers, sump/suction strainers, duplex strainers, and Y-strainers.

How do I choose between basket, Y-type, cone, tee, sump, and duplex strainers?

Selection depends on service conditions and how you plan to maintain the strainer. Basket strainers are often chosen for higher debris-holding capacity and easier cleanout. Y-strainers are common in tighter layouts and higher-pressure services. Cone strainers provide a high open area in-line. Tee strainers fit compact side-pocket layouts. Sump/suction strainers protect pump suction from reservoirs or pits. Duplex strainers are used when you need continuous filtration while cleaning one side.

What materials are available for RedLineIPS pipe strainers?

Strainers are commonly supplied in stainless steel, with other materials available as required by your piping specification and service environment. Body and screen materials can be matched to corrosion requirements, and screen/mesh selection is supplied to your filtration needs.

What information do I need to request a quote for pipe strainers?

Provide line size, end connection type, pressure class (or design conditions), operating temperature, fluid type, preferred strainer style, screen opening (mesh/perforation), material requirements for body and screen, quantity, and any project requirements for finish, tagging, or documentation.