Reinforcement Pads

- Home

- Metallic Piping Accessories

- Reinforcement Pads

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

What is a Reinforcement Pad?

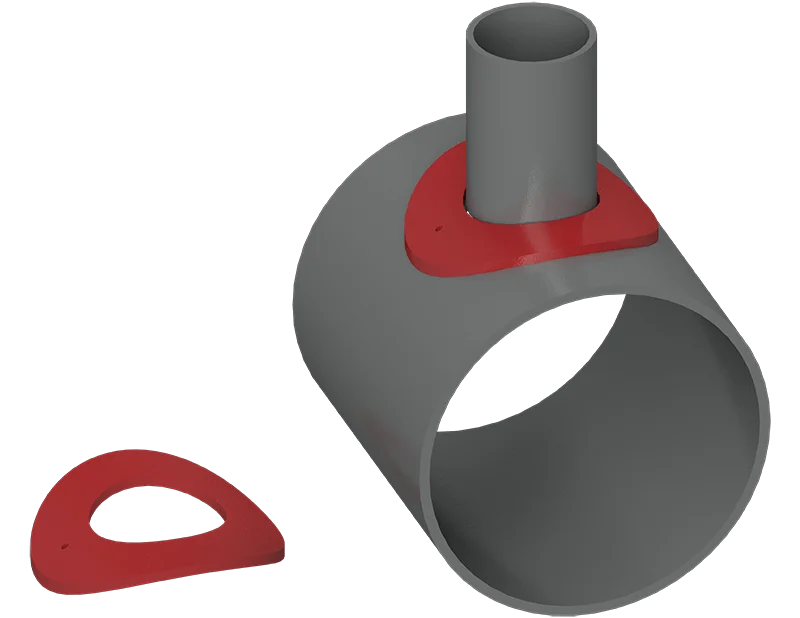

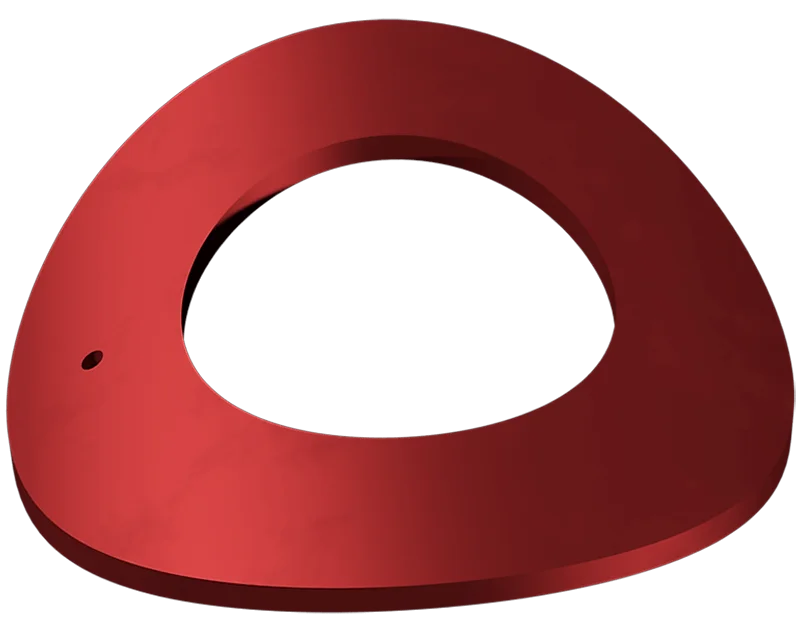

A Repad is a reinforcing, doughnut-shaped, rolled plate designed to allow a branch to be welded to a main pipe or vessel by “replacing perimeter of the area” of the main pipe or vessel that was cut out. The dimensional data (size and thickness) of the Repad is determined by engineering calculations. Repads are a cost-effective solution that eliminates the need for a three-way pipe fitting (Tee) with multiple weld requirements.

As such, Cogbill’s RedLineIPS heavy-duty Reinforcement Pads, Reinforcing Pads, or Repads for short, stand as integral components in the world of industrial piping systems and vessel connections in the petrochemical and gas industries. These doughnut-shaped rolled plates serve in the following manners:

- Reinforcing the structural integrity of pipe-to-pipe or vessel-to-pipe connections.

- Securely linking pipes to pipes and vessels.

The Purpose of Repads

Reinforcement Pads serve a dual purpose in the realm of piping systems and vessel connections. They are designed to offer reinforcement in two primary scenarios:

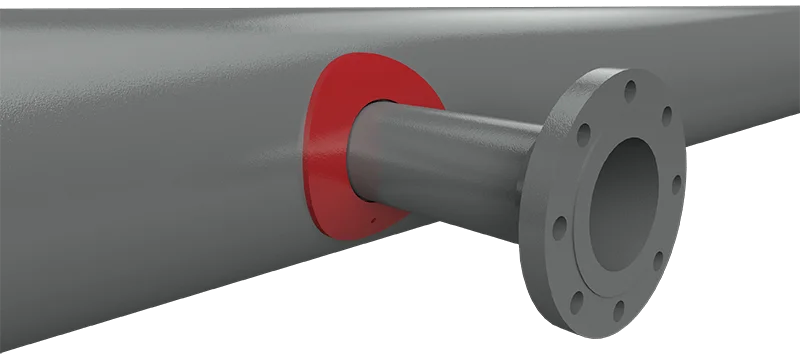

Branching Pipes

- The Challenge: In numerous situations, the need arises to branch off from a main pipe to create additional connections. Cutting a hole in the main pipe to facilitate this branching, however, creates a high-stress region at the cut location.

- The Solution: A Reinforcement Pad becomes essential when engineers validate that the joint requires additional reinforcement. This doughnut-shaped rolled plate effectively replaces the perimeter of the material that was cut out of the main pipe, allowing the secure attachment of a branch pipe. This not only reinforces the structural integrity of the joint but also simplifies the connection process, eliminating the need for complex fittings such as three-way pipe fittings (Tees).

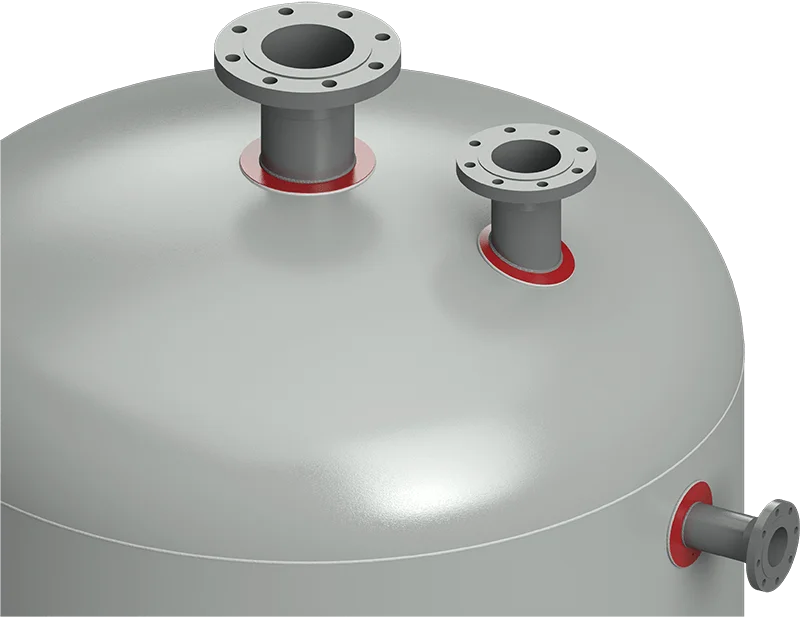

Connecting Pipes to Vessels

- The Challenge: Connecting pipes to vessels, such as tanks or containers, presents a unique set of challenges. Just as the case with branching off a pipe, cutting a hole in the vessel to facilitate this branching creates a high-stress region at the cut location of the vessel. This will require a remedy, since such connections must withstand varying pressures, loads, and materials without compromising the vessel's integrity.

- The Solution: In such cases, Reinforcement Pads, or Repads, play a critical role in providing a stable platform for welding the pipe to the vessel. The dimensions of the Repads are meticulously determined through engineering calculations, ensuring that the connection is tailored to the specific requirements of the application. By distributing stress and reinforcing the weld, Repads ensure the strength and safety of the vessel-to-pipe connection.

RedLineIPS Repad Customization

Features of RedLineIPS Repads

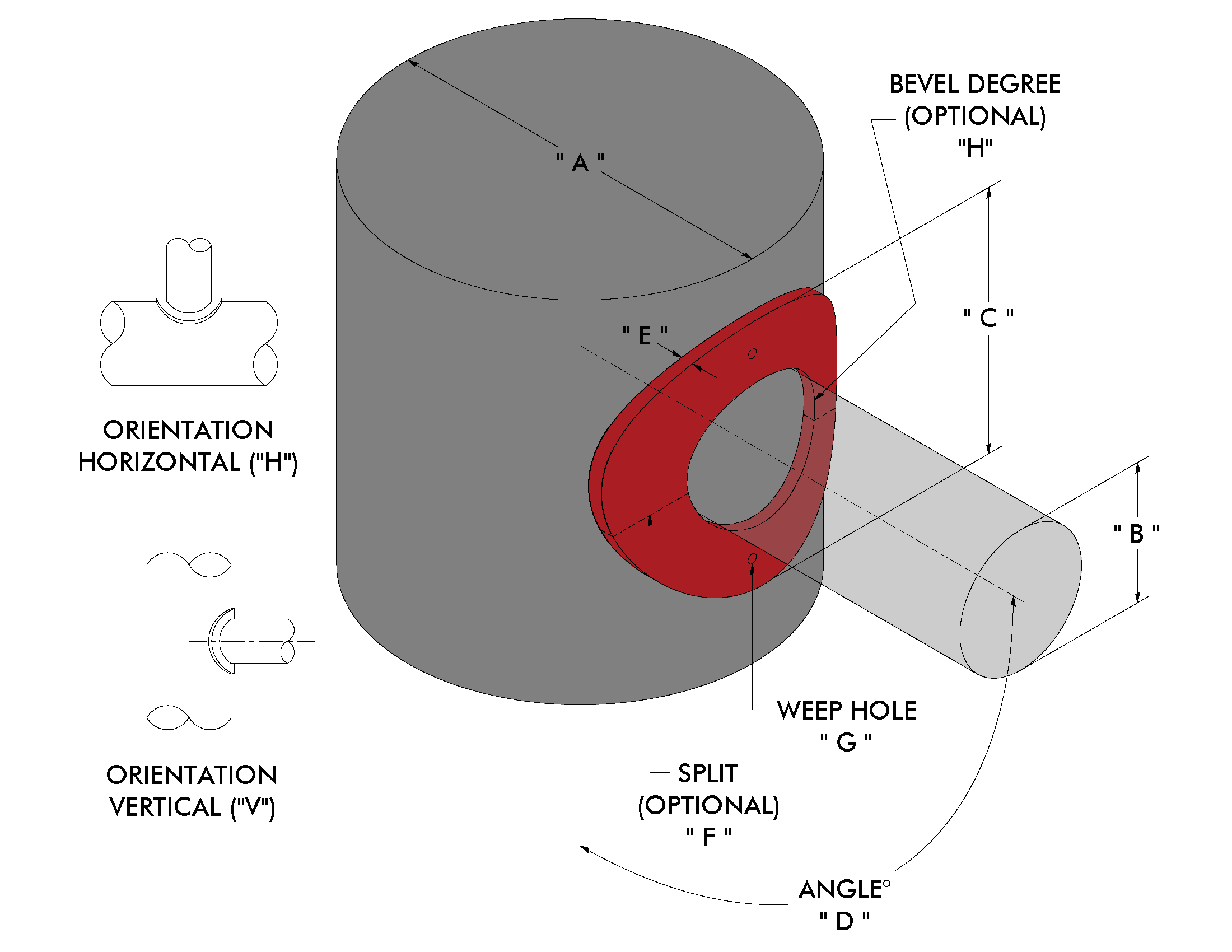

Cogbill’s RedLineIPS Reinforcement Pads can be further customized to include features such as “weep holes” used to relief pressure when trapped gases need to be vented during the welding process. These weep holes can also be threaded to accommodate the attachment of pressure gauges or test ports for subsequent leak testing. Another option is to bevel the inside diameter of the Repad to allow for better welding during installaiton.

Furthermore, RedLineIPS Reinforcement Pads do not necessarily need to be manufactured as single pieces. In situations where it is required or more practical, Repads can be fabricated as multiple pieces, offering enhanced flexibility in design and installation.

Ordering Cogbill’s RedLineIPS Reinforcement Pad

| A: Main Pipe Outside Diameter (in) | B: Branch Outside Diameter (in) |

| C: Repad Outside Diameter (in) | D: Branch-to-Main Line Angle (°) |

| E: Repad Thickness (in) | F: Split Repads Option (Y/N) |

| G: Weep Hole Option (Y/N) | H: Bevel Option (Y/N) (Degree°) |

| Weep Hole Diameter (in)? | Threaded Weep Hole (Y/N)? |

| Weep Hole Count (1,2) | Pipe Orientation (Horizontal/Vertical) |

| Repads Material (Specify type, grade, thickness, AML, etc. | |

| Quantity: Small and large orders welcome | |

To order using our online RFQ form, click here.

Alternatively, to download an easy-to-use order form for Reinforcement Pads, click here.

FAQ's

Typical Queries and Information

What is a Reinforcement Pad (Repad)?

A Reinforcement Pad (Repad) is a rolled, doughnut-shaped plate that’s fit to a pipe or vessel around a branch opening to restore/reinforce strength removed by the cutout. It provides added reinforcement area around the connection so the branch can be welded in and meet code requirements.

When do I need a Repad instead of a tee or forged branch fitting?

Repads are used when the branch connection requires additional reinforcement area around the opening. Depending on the job, a Repad may be more practical than a fabricated tee or more economical than specialty fittings—especially on larger sizes, non-standard angles, or nozzle-to-vessel work.

How are Repad dimensions determined?

Repad outside diameter and thickness are established by the project’s code calculations and issued drawings (based on run/branch size, wall thickness, pressure, temperature, and allowable stress). Cogbill then fabricates the Repad to those specified dimensions and material requirements.

What are “weep holes” in a Repad and why are they used?

A weep hole (vent/telltale hole) is a small opening in the Repad used to vent trapped gases during welding and to provide a telltale path that can indicate leakage between welds during service. When specified, it can also be threaded for certain test setups or ports.

What information do I need to request a quote for a Reinforcement Pad?

Repads are specialized and dimension-heavy parts—there are many critical measurements and options that affect fit-up, code compliance, and how the pad must be manufactured. To make this easy (and avoid missed dimensions), Cogbill created a downloadable, fillable PDF form you can complete online. It includes drawings that show exactly what each dimension means, so you can send us everything we need in one clean package.