Slide Plates

- Home

- Metallic Piping Accessories

- Slide Plates

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

What is a Slide Plate?

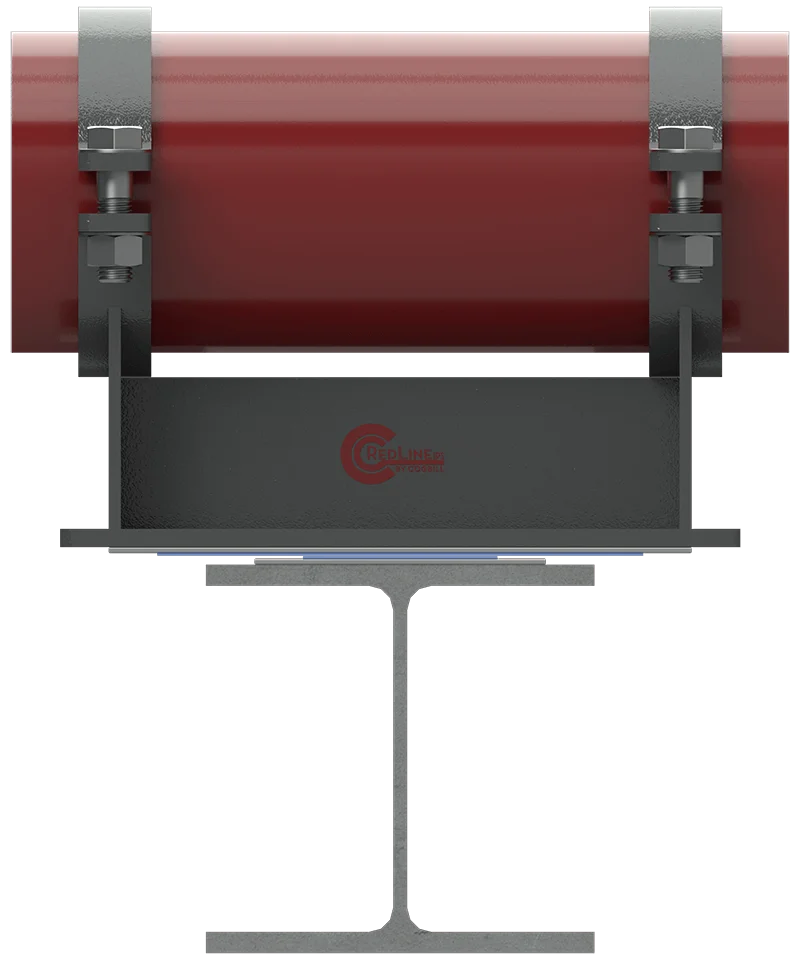

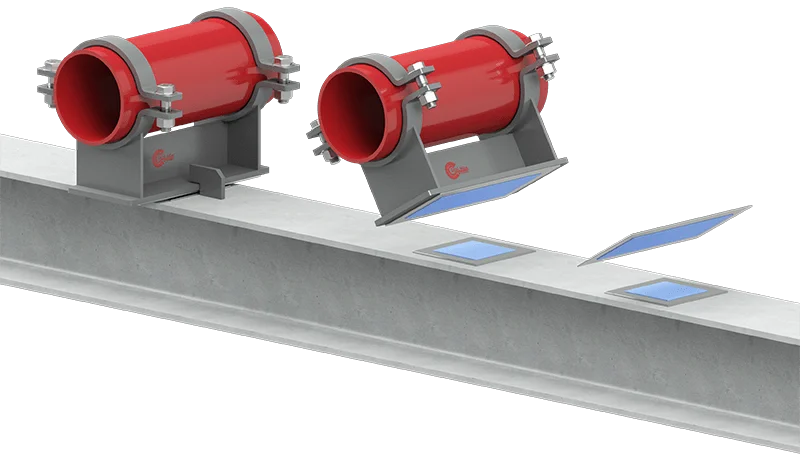

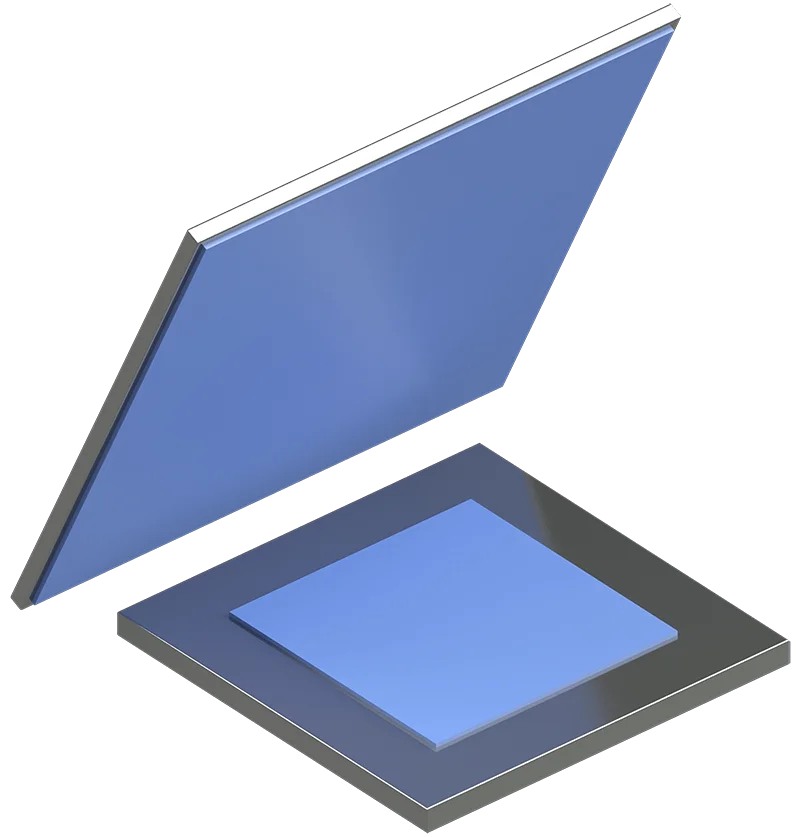

RedLineIPS, by Cogbill Construction, offers slide plates designed to meet the rigorous demands of piping systems in the petrochemical and gas industries. In such settings, slide plates are typically utilized in a sandwich configuration. This entails two sets of steel plates, often termed as “backing plates,” sandwiching a specialized material with a low coefficient of friction, such as PTFE, graphite, bronze, or polished stainless steel. These components are expertly bonded with a robust adhesive. The top plates are sometimes larger, and they consist of a carbon steel backing plate with a polished stainless steel inside plate, or at times PTFE or other materials are used for the inside plate. The bottom plate typically consists of a smaller carbon steel backing plate with a recessed low friction PTFE material bonded to it.

This image is interactive. Click on any red marker for more information.

1 of 5 Top & Larger Backing Plate 2 of 5 Material with Low Coefficient of Friction 3 of 5 Material with Low Coefficient of Friction 4 of 5 Lower and Smaller Backing Plate 5 of 5RedLineIPS Slide Plate Components

The low-friction material interfaces are positioned in opposing directions within the sandwich structure (meat and cheese portion). One metal plate (larger bread slice) is securely welded to the bottom of a pipe support, pipe shoe, or hold-down pipe clamp, among others, while its counterpart (the smaller bread slice) is welded to the top of the supporting structure. This innovative design achieves the following:

- Allows controlled movement of pipes.

- Minimizes friction.

- Allows for thermal expansion or contraction.

- The larger top plat provides an umbrella effect preventing dust and debris from collecting on the smaller plate and the low-friction plate.

RedLineIPS slide plates ensure pipes can adapt and move without compromising the integrity of the piping system.

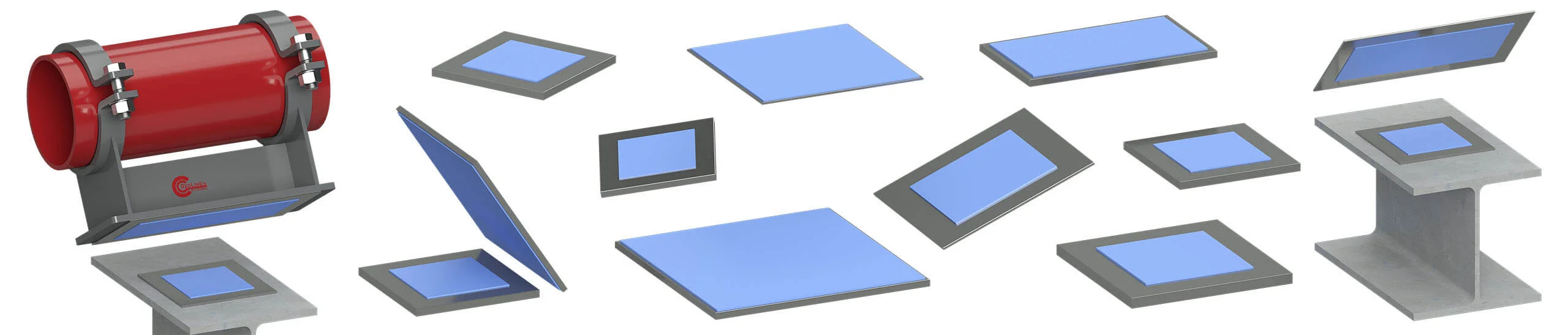

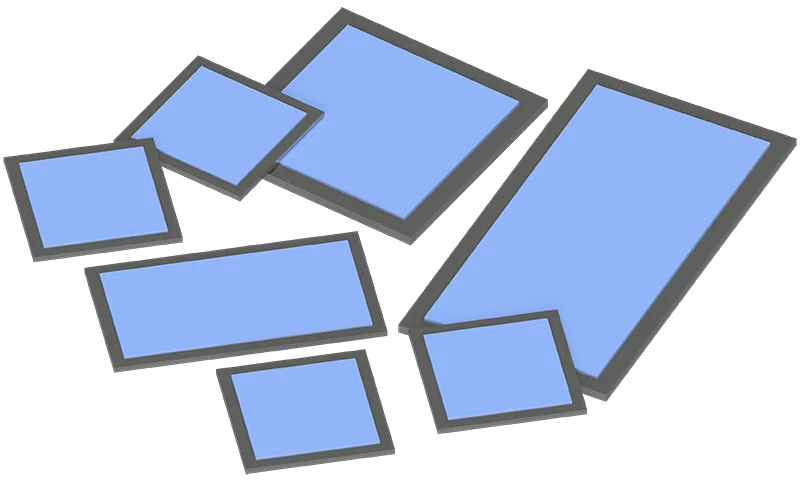

Types of RedLineIPS Slide Plates

- PTFE Slide Plates with 25% Glass Filling

Remarkably resilient, these slide plates by RedLineIPS demonstrate exceptional endurance within a temperature range of -320°F to 500°F. They support loads of up to 2,000 psi, with a low coefficient of friction ranging from 0.01 to 0.2. Applications span diverse settings such as pipe supports, cross-beam and girder slip joints, vessels, air preheaters, and a broad spectrum of industrial and architectural contexts.

- Graphite Slide Plates

Reserved for systems operating under exceptional pressure and extreme heat, pure graphite slide plates by RedLineIPS stand as the preferred choice. These plates offer reliable support for critical industrial operations, exhibiting a temperature range of up to 1,000°F, supporting loads up to 2,000 psi, and possessing a coefficient of friction of 0.15.

Benefits of RedLineIPS Slide Plates

- Reduction of Friction

- Accommodating Thermal Expansion

Vital in accommodating thermal expansion and contraction, RedLineIPS slide plates provide a controlled and low-friction surface for the natural movements of pipes and equipment. This ensures that thermal stresses are managed effectively, reducing the risk of damage and failure within the piping system.

- Even Load Distribution

RedLineIPS slide plates play a pivotal role in distributing loads and weight evenly across supporting structures. This even distribution helps prevent localized stress concentrations, promoting the longevity and safety of the entire system.

- Vibration and Misalignment Mitigation

In dynamic industrial environments prone to vibrations and equipment misalignment, RedLineIPS slide plates excel at absorbing and dampening vibrations. This capability significantly reduces the risk of structural damage and equipment fatigue, ensuring that pipes and equipment remain properly aligned during operation.

- Enhancing System Longevity

By providing a protective layer between heavy structures, RedLineIPS slide plates contribute to the prolonged lifespan of both supporting structures and the pipes or equipment they support. This preventive measure minimizes wear and damage, reducing the need for frequent maintenance and replacements.

- Corrosion Prevention

In corrosive environments, the use of non-metallic slide plate materials, such as PTFE, contributes to corrosion prevention. These materials create a protective barrier between metals, mitigating the risk of galvanic corrosion and other forms of metal degradation—particularly crucial in chemical plants and refineries exposed to corrosive substances and ones near coastal regions and offshore.

- Cost Savings

- Enhanced Safety

Above all, RedLineIPS slide plates elevate safety standards in industrial environments. They prevent sudden equipment movements, structural failures, or accidents caused by excessive friction or misalignment. In industries where hazardous materials and conditions prevail, creating a safer work environment is paramount.

Contact us today to learn more about our RedLineIPS slide plates, their different configurations and customization, and how they can enhance your piping systems and heavy equipment.

FAQ's

Typical Queries and Information

What does a slide plate do in a piping system?

A slide plate creates a low-friction interface at a support point so the pipe can move axially, laterally, or with minor rotation as temperatures change and vibration occurs. This helps reduce restraint loads, protect coatings, and minimize wear at the support-to-steel contact surface.

How are slide plates constructed?

Cogbill’s RedLineIPS slide plates are typically built with a steel backing plate and a bonded low-friction bearing surface (commonly PTFE-based or graphite-based). Depending on the detail, the slide may be supplied as a single plate, a “sandwich” style assembly, or as a mating pair (bearing surface plus mating surface) to match the issued support drawing.

Where are slide plates typically used?

Slide plates are commonly used under pipe shoes, guides, and hold-down clamps on pipe racks and other high-movement locations—anywhere controlled slip is preferred instead of forcing movement into the pipe, welds, or connected equipment.`

What slide plate bearing materials are commonly used?

PTFE-based slide surfaces are widely used for very low friction and general-purpose performance in many industrial environments. Graphite-based slide surfaces are often selected where higher temperatures are expected. Other combinations (including stainless mating surfaces and project-specified alloys/materials) are used when required by the piping class, environment, or client standard.

How do I specify the right slide plate for my project?

Provide dimensional information, the support type (shoe/guide/hold-down), pipe size, expected movement direction and travel, operating temperature at the sliding interface, environment (corrosive/offshore/dirty service), and any project standards for materials/finish. Cogbill then fabricates the RedLineIPS slide plate configuration to match the project’s issued drawings and specifications.