Spec Blinds & Rings

- Home

- Metallic Piping Accessories

- Spectacle Blinds & Paddles

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

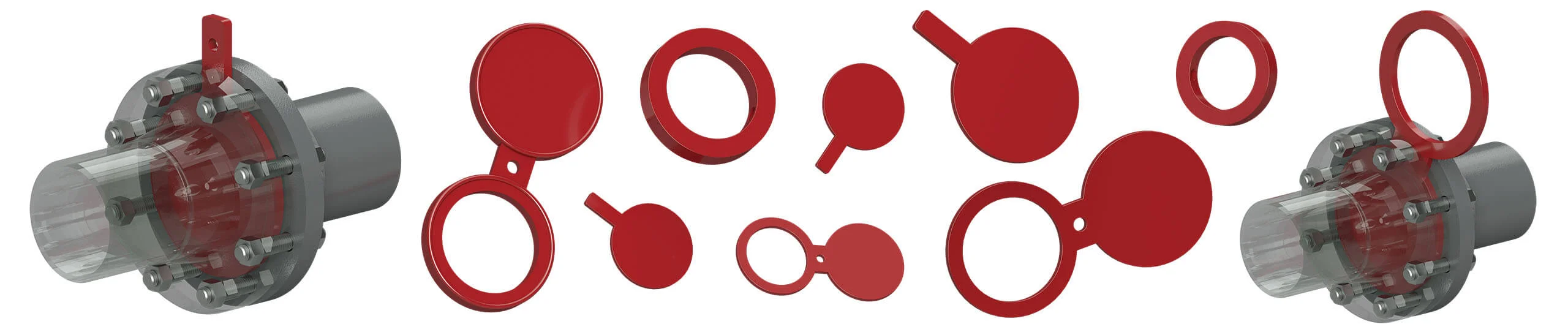

RedLineIPS Spectacle Blinds, Paddles & Rings

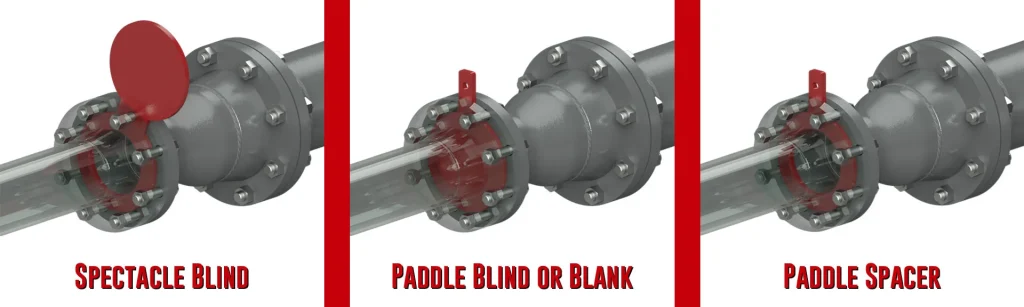

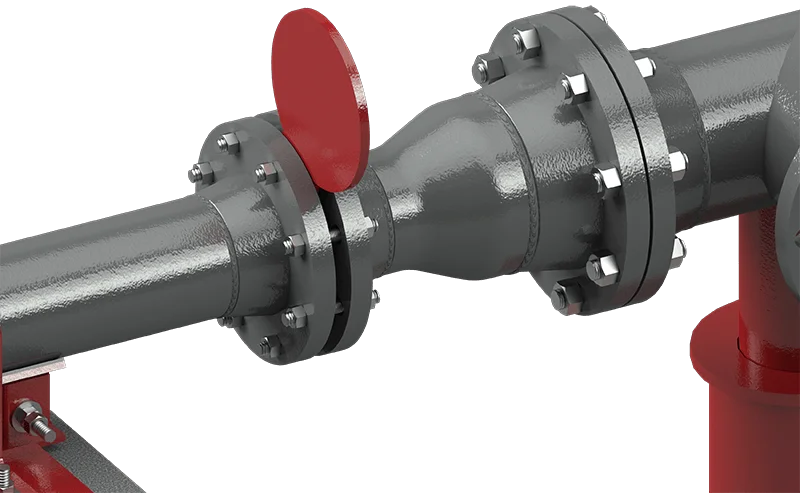

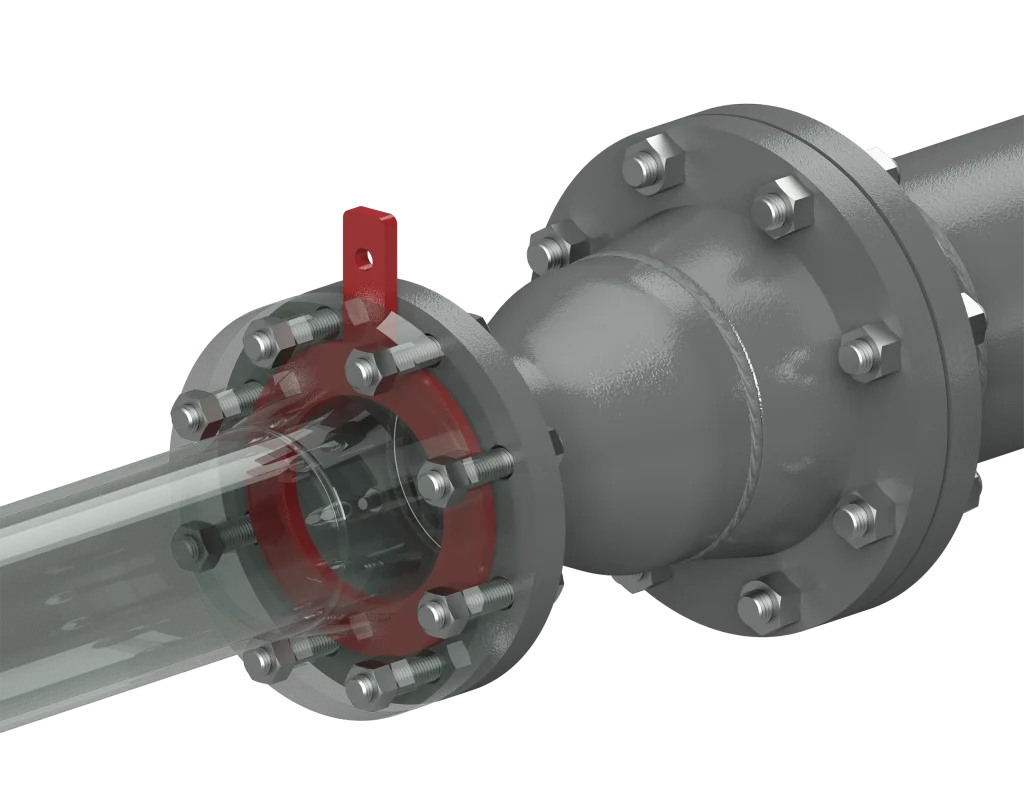

Blinds, such as spectacle blinds and paddle blinds or blanks, are isolation devices commonly used in industrial piping systems. Paddle blinds consist of a single metal disk that can be inserted between two flanges, stopping the flow of fluid or gas during maintenance, while a spacer would allow fluids or gasses to flow unimpeded.

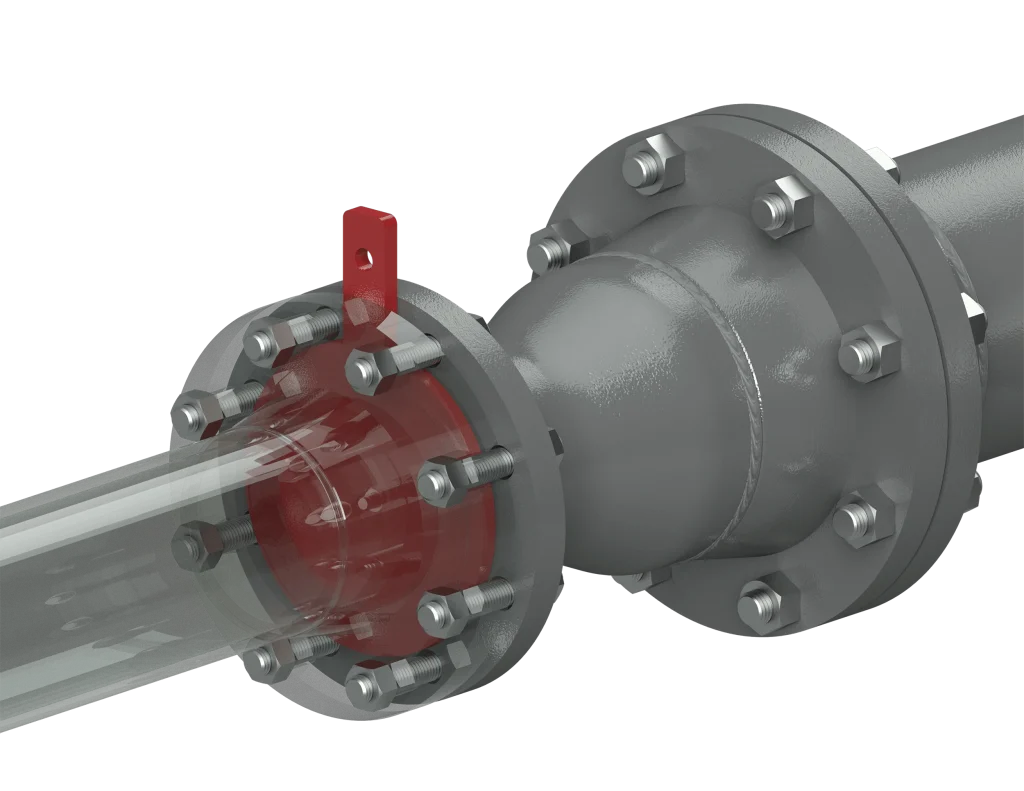

Spectacle blinds serve the same functions as blinds and spacers but in a two-in-one configuration, comprising two interconnected metal disks. One side is designed to isolate material (blank or blind), while the opposite side features a circular opening (spacer) whose diameter matches the bore diameter of the pipe, enabling material flow. The connection between the two sides is typically facilitated by a region known as the “pivot” or “rotational hub,” often featuring a central hole for the seamless rotation of the blank and spacer sides.

Blinds and spacers can be manufactured from carbon steel, stainless steel, or any customer-specific alloy material and finish. Sizes and thickness vary according to the pressure class, and our RedLineIPS brand of blinds and spacers can accommodate most customer requirements.

RedLineIPS Spectacle Blinds

What is a Spectacle Blind?

A Spectacle Blind, also known as a Figure-8 Blind in the industry, is a specialized piping component with a distinctive figure-8 or eyeglasses-like shape when viewed from the side, hence the names. It comprises two metal disks—one solid and the other with an opening—connected by a bridge or line. This figure-8 configuration allows for straightforward identification of the blind’s open or closed position, after installation. These unique devices serve critical roles in piping systems such as controlling the flow of fluids, isolating sections of pipelines, and facilitating maintenance operations.

Functionality of Spectacle Blinds

The primary function of Spectacle Blinds is to regulate fluid flow within pipelines. By rotating the blind, operators can either align the open position, or spacer, with the pipeline for unobstructed flow, or position the solid disk, or blank, to block flow entirely. This dual functionality makes Spectacle Blinds an invaluable tool for isolating sections of pipelines in response to various system requirements.

Spectacle blinds are used primarily in piping systems that need to be periodically cleaned, inspected, or repaired. By closing the hole in the center of the flange, the spectacle blind effectively isolates the section of piping that needs to be worked on, while allowing the rest of the pipeline to continue operating normally. Spectacle blinds are particularly useful in applications where complete shutdown of the pipeline is not feasible or practical.

Material Composition of Spectacle Blinds

Cogbill’s RedLineIPS Spectacle Blinds are engineered to withstand the demanding conditions encountered in industrial settings. The choice of material is influenced by factors such as the nature of the fluid or gas being transported, pressure ratings, temperature, etc. Common materials include carbon steel, stainless steel, and alloy steel, chosen for their corrosion resistance, durability, compatibility with various fluids and gases, environmental considerations, and project specifications. Technical specifications include:

Material Options

- Carbon Steel (ASTM A105)

- Stainless Steel (ASTM A182)

- Alloy Steel (ASTM A182)

Size Range

- Cogbill’s RedLineIPS heavy-duty blinds are available in a comprehensive range of sizes and thicknesses to meet diverse project requirements.

Pressure Ratings

- Engineered to handle high-pressure applications with precision and reliability.

Operating Temperature

- Suitable for a broad range of temperatures encountered in oil and gas operations.

Design Standards

- Compliant with ASME B16.48 and API 590 standards to ensure the highest quality and reliability.

Applications of RedLineIPS Spectacle Blinds

Flow Control

- Enables precise control over fluid flow by easily switching between open and closed positions.

Maintenance Facilitation

- Provides a temporary isolation point in pipelines, allowing maintenance personnel to conduct repairs or inspections without shutting down the entire piping system.

Thermal Expansion Management

- Accommodates thermal expansion and contraction, preventing stress or damage to the pipeline.

Pressure Testing

- Essential for conducting pressure tests on specific sections of a pipeline.

Installation and Removal of RedLineIPS Spectacle Blinds

Installing a Spectacle Blind involves aligning the blind’s open position with the desired flow direction and securing it in place. The bridge connecting the two discs ensures stability. Gaskets are used to create a tight seal, preventing leakage during operation.

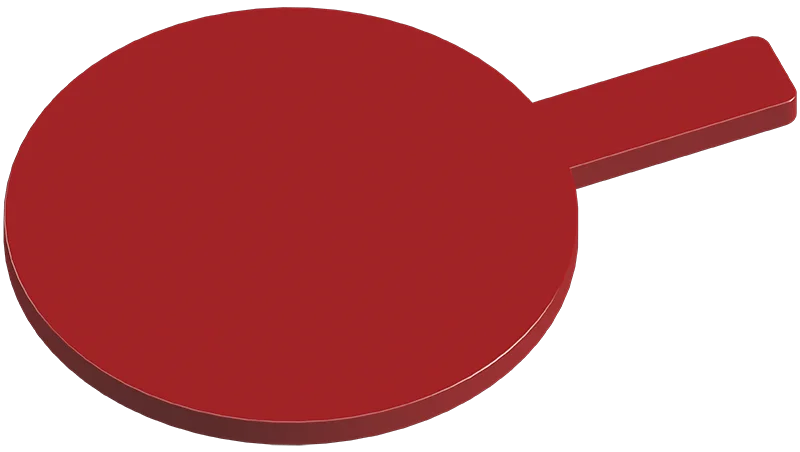

RedLineIPS Paddle Blanks or Paddle Blinds

What is a Paddle Blind or Paddle Blank?

Paddle blanks serve a pivotal role in industrial piping systems, allowing for the isolation of specific sections for maintenance, repairs, or changes in the operational configuration. RedLineIPS Paddle Blanks, in particular, are heavy-duty piping components designed to provide a secure and effective means of temporarily blocking off sections of a pipe, ensuring the safety of personnel and the integrity of the entire system.

RedLineIPS Paddle Spacers

What is a Paddle Spacer?

A Paddle Spacer is a specialized component utilized in piping systems to temporarily replace a solid spacer blind when the pipeline needs to be open rather than closed. Unlike traditional spacer blinds that completely obstruct the flow, a Paddle Spacer features a strategically placed hole or opening. This design also allows for controlled fluid flow, making it an ideal solution for scenarios where selective isolation or opening of specific pipe sections is required.

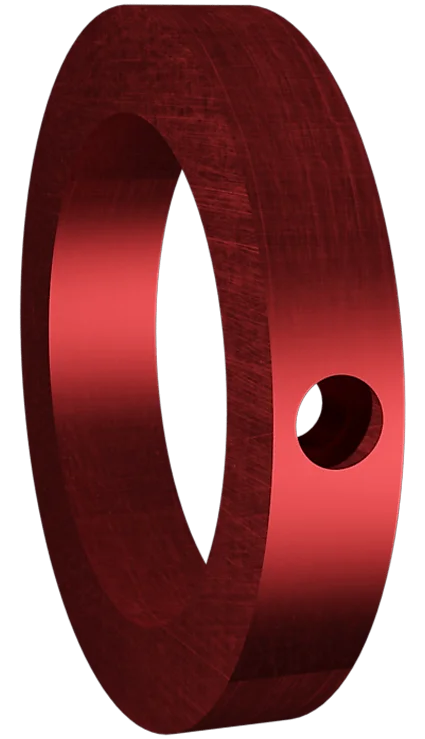

RedLineIPS Bleed Rings

What is a Bleed Ring?

A Bleed Ring is a specialized component used in piping systems to provide a controlled opening for bleeding or draining fluids from the pipeline. Also known as drip rings, these devices are designed with a flange-like structure that features one or more openings. The purpose of a Bleed Ring is to allow the safe extraction of fluids, typically during maintenance, pressure relief, or sampling processes. They are strategically installed between flanges, offering a controlled pathway for the release of fluids without compromising the overall integrity of the piping system.

Why RedLineIPS Blinds, Spacers & Rings?

At Cogbill, we take pride in delivering excellence in every product. Our Blinds are manufactured with a commitment to quality, adhering to industry standards to ensure safety, reliability, and longevity. Contact us today to discuss your project needs and discover how our RedLineIPS Spectacle Blinds can enhance the efficiency and safety of your operations

FAQ's

Typical Queries and Information

What are spectacle blinds, paddle blinds, and paddle spacers?

They’re flange-installed line blinds used to isolate or open a piping section without changing the flange set. A paddle blind (spade/paddle blank) is a solid plate that blocks flow. A paddle spacer has the same outline but an open bore for flow. A spectacle blind is a “figure-8” piece that combines both so it can be rotated between the open (spacer) and closed (blind) positions.

When should I use a spectacle blind instead of a separate paddle blind and spacer?

Use a spectacle blind when you want the open and closed positions physically linked at the same flange location for routine operations, and you want a quick visual confirmation of the current position. Use separate paddles/spacers when space is tight, when parts will be handled and stored separately, or when isolation is infrequent and you don’t want the combined figure-8 style at that joint.

What is a bleed ring and when would I use one?

A bleed ring is a ring installed between flanges with one or more ports to provide a controlled point for venting, bleeding, draining, sampling, or pressure verification—without breaking the main flange joint.

What materials and finishes are available?

Cogbill manufactures RedLineIPS spectacle blinds, paddles, spacers, and bleed rings in carbon steel, stainless steel, and customer-specified alloys to match the piping specification and service environment. Finishes are supplied per project requirements, such as mill finish (bare), painted/coated systems, or other specified protection.

What information do I need to request a quote?

Provide NPS, pressure class, item type (spectacle blind, paddle blind, paddle spacer, bleed ring), material spec/grade, thickness (or indicate “per standard”), applicable standard (commonly ASME B16.48 if required by the project), quantity, and any options such as handle style, marking/ID, coating/finish, and port size/location (for bleed rings).