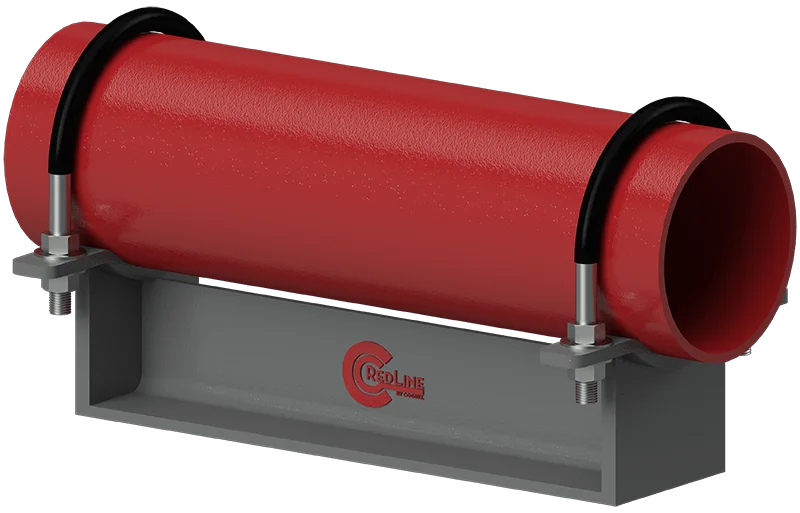

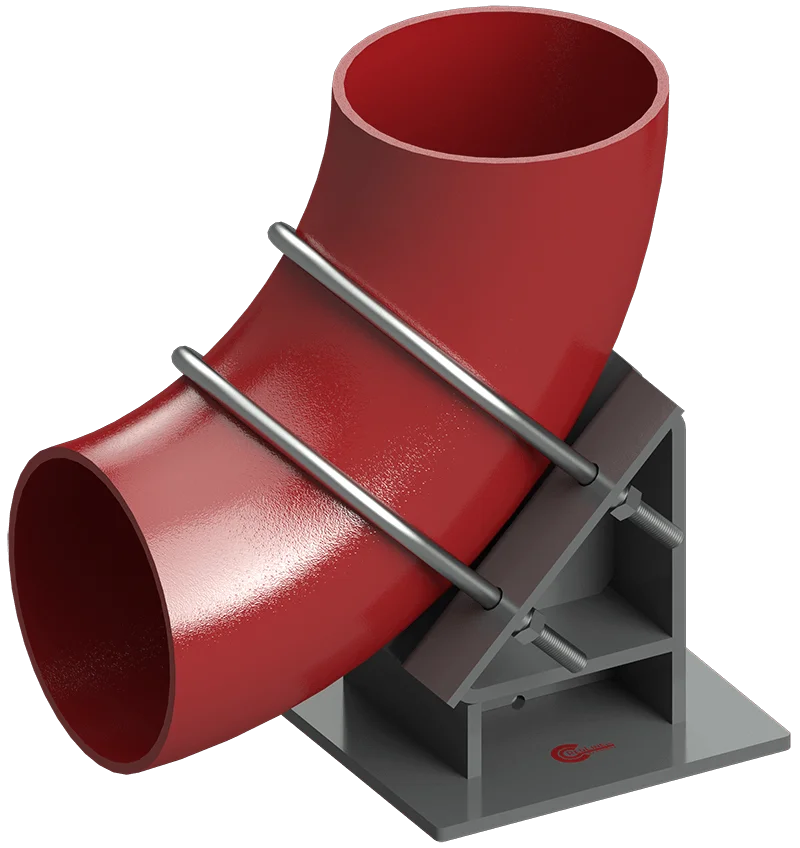

U-Bolts

U-Bolts are versatile, U-shaped fasteners used to secure pipes to structures, ensuring stable support and maintaining system alignment. They are essential in residential, commercial, and industrial piping installations for reliable and effective pipe management.

Metallic Piping Accessories

Photo Gallery

Let’s Start Work

Together

What is a U-Bolt?

U-Bolts are versatile fastening devices specifically designed to secure pipes to various structures, ensuring stable and reliable support. Shaped like the letter ‘U’ with threaded ends that accommodate nuts, U-Bolts wrap around the pipe and are anchored to walls, ceilings, or floors. These supports are critical for maintaining the alignment and integrity of piping systems in residential, commercial, and industrial environments. U-Bolts are essential for both routine installations and complex configurations, providing a straightforward yet effective solution for managing and organizing pipes.

Distinguished by their characteristic U-shaped design featuring threaded ends, U-Bolts play a vital role as essential fasteners across diverse industries, particularly in the realm of piping and pipeline supports and fasteners. The primary function of U-Bolts is rooted in their capacity to deliver robust support to pipes, thereby bolstering the structural integrity and stability of piping systems. Operating as versatile restraints, RedLineIPS U-Bolts excel in mitigating line vibrations, introducing a crucial element of rigidity to the piping system. This pivotal role serves to prevent unintended pipe movements, safeguarding against potential damage and ensuring prolonged operational safety.

Renowned for their simplicity and broad applicability, RedLineIPS U-Bolts come in an array of sizes, thicknesses, and material composition, solidifying their status as a cornerstone in piping support solutions. Beyond their conventional application as pipe restraints, U-Bolts showcase additional functionalities as guides, providing a diverse range of benefits when strategically incorporated.

Whether employed as standalone solutions or as options to RedLineIPS Adjustable Pipe Supports and RedLineIPS Pipe Shoes, U-Bolts facilitate installation without the need for field-welding, further amplifying their usability and reaffirming their popularity as efficient pipe supports.

U-Bolts Applications in Industrial Piping Systems

In the realm of industrial piping systems, RedLineIPS U-Bolts play a pivotal role across various applications:

- Pipe Support: U-Bolts secure pipes to structures, preventing vertical and horizontal movement, ensuring pipes remain aligned and stable under various operational conditions.

- Vibration Suppression: U-Bolts minimize vibrations caused by fluid flow or external factors, reducing stress on the piping system and connected equipment. This also helps reduce noise levels, contributing to a quieter and more stable operational environment.

- Anchoring: U-Bolts anchor pipes to fixed points, providing stability in dynamic systems where pipes might otherwise shift or move due to pressure changes or thermal expansion.

- Guidance: U-Bolts help guide pipes along predetermined paths, ensuring they follow a specific route through the facility. This is crucial in complex piping systems where precise routing is necessary to avoid obstacles and ensure efficient flow.

- Lateral Restraints: U-Bolts provide lateral support to prevent side-to-side movement of pipes, maintaining the structural integrity of the piping system, especially in environments subject to lateral forces such as wind or seismic activity.

RedLineIPS U-Bolts as Anchor

Using U-Bolts as anchors offers a strategic approach to ensuring the stability and security of piping systems, particularly in scenarios where it’s critical to prevent pipe movement. In such cases U-Bolts are installed to restrict pipe motion in all three dimensions—laterally, vertically, and longitudinally (axially) — acting as a comprehensive restraining force.

This functionality is crucial for adding stability to pipes, preventing them from bouncing, sliding, or experiencing unintended shifts. The benefits of using U-Bolts as anchors are manifold; they not only reduce thermal movement that could lead to shifts and damage in pipes but also secure the piping against external forces such as wind, earthquakes, or other environmental influences. Moreover, U-Bolts play a pivotal role in minimizing vibrations within the piping system, thereby helping to prevent issues like surface abrasions or ruptures, plus mitigating noise. Proper installation is key to leveraging the full benefits of U-Bolts as anchors, ensuring they provide the intended support and stability to the piping system.

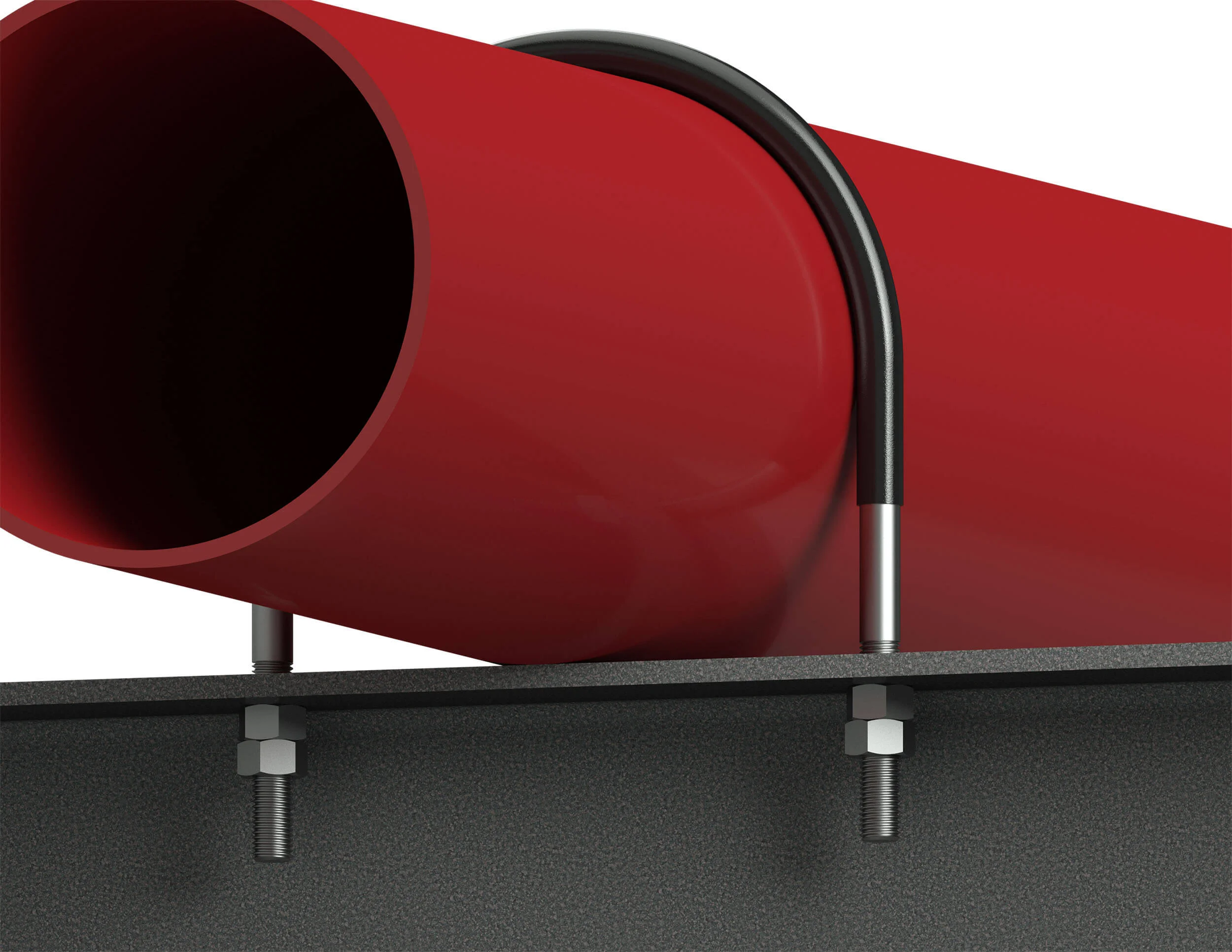

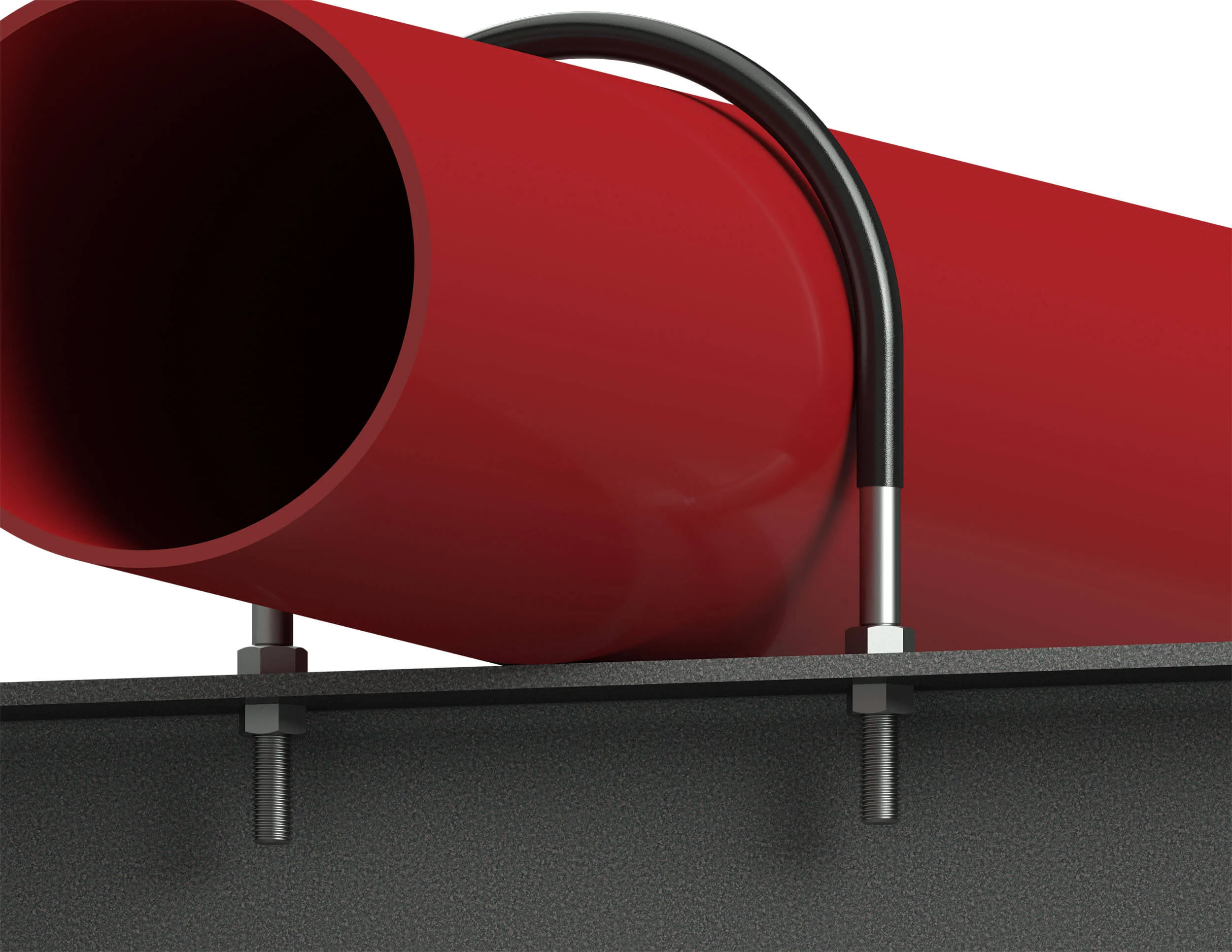

The installation process for U-Bolts as anchors involves placing both Bolts at the bottom of the support structure and tightening them securely against the pipe. Ensuring a snug fit without any spacing between the U-Bolt and the pipe’s surface is crucial for optimal performance.

Employing RedLineIPS U-Bolts as anchors typically involves considerations for corrosion resistance, with materials such as stainless steel or those featuring a galvanized coating or non-metallic isolation liners being utilized. The quality of the U-Bolts is paramount, influencing both their longevity and the broader performance of the piping system. Understanding the steel grade and composition necessary for the specific system is essential in selecting RedLineIPS U-Bolts that will withstand the intended conditions.

RedLineIPS U-Bolts as Guides

Installation of RedLineIPS U-Bolts as guides involves placing bolts on the top and bottom of the support beam, with a deliberate gap between the U-Bolt and the pipe’s surface after tightening. This gap ensures that the U-Bolt functions as a guide, allowing axial movement while still offering support. The use of U-Bolts as guides distributes pressure evenly across surfaces, reducing stress on specific points and preventing potential vulnerabilities in the system.

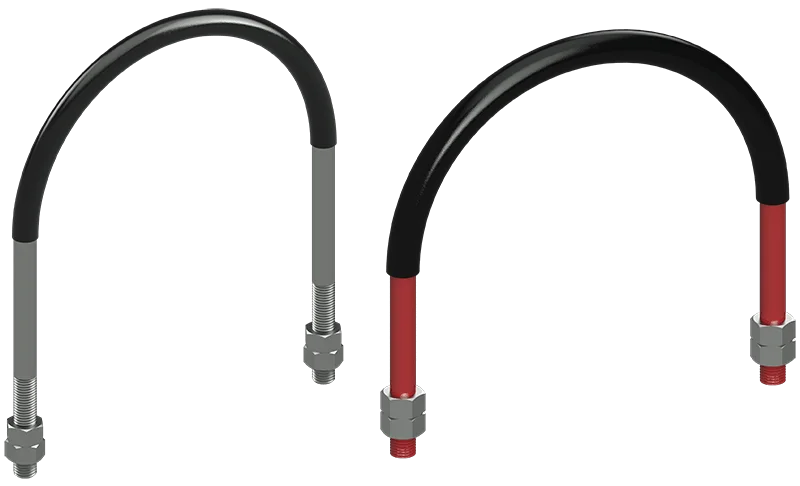

When selecting RedLineIPS U-Bolts for use as guides, considerations include corrosion resistance, material strength, and the overall quality of the U-Bolts. Opting for materials like stainless steel or those with protective coatings, such as galvanized or with thermoplastic coatings, enhances their durability, particularly in corrosive environments.

Material Composition of U-Bolts

RedLineIPS U-Bolts are manufactured from diverse materials, each carefully chosen to meet specific performance requirements. The primary materials used in U-Bolt construction include:

- Plain Carbon Steel: Renowned for its balance of strength and cost-effectiveness, plain carbon steel is a common choice for U-Bolts. Its robust properties make it suitable for various applications. Additionally, plain carbon steel can be further fortified against corrosion through galvanization or other protective coatings such as rubber liner materials.

- Stainless Steel (304 and 316): Recognized for superior corrosion resistance, stainless steel U-Bolts are pivotal in challenging environments. Grade 304 is a general-purpose option, while Grade 316 excels in corrosive settings, making it ideal for marine and industrial applications.

- Alloy Steel: U-Bolts forged from alloy steel offer heightened strength and durability. Alloying elements such as chromium, molybdenum, or nickel enhance mechanical properties, tailoring the material for specific industrial demands.

The versatility of RedLineIPS U-Bolt material choices allows industries to select based on strength requirements, environmental considerations, and budget constraints. Applying coatings like galvanization to plain carbon steel further extends its lifespan and enhances corrosion resistance, ensuring that U-Bolts meet the diverse demands of industrial applications.

RedLineIPS U-Bolts with isolation liners

U-Bolts can also come with a rubber liner at the contact region with the pipe, to add further protection and benefits. Such isolation liners are typically made from materials with excellent resilience, durability, and resistance to corrosion and environmental factors, especially with facilities at coastal areas or offshore platforms. The primary purpose of these isolation liners is to provide a cushioning effect and minimize friction between the U-Bolt and the supported pipe. This helps in preventing damage to the pipe’s surface and reducing the transmission of vibrations and noise. Eliminating metal-to-metal contact to prevent galvanic corrosion is another benefit. Common types of isolation liners used with RedLineIPS U-Bolts include:

- Neoprene isolation liners: Neoprene rubber is known for its versatility, resilience, and resistance to oils, chemicals, and weathering. Neoprene liners are often used to protect pipes from abrasion and dampen vibrations.

- EPDM isolation liners: EPDM (ethylene propylene diene monomer) rubber offers excellent resistance to weathering, ozone, and UV exposure. EPDM liners are suitable for outdoor applications and provide effective cushioning and vibration isolation.

- Nitrile isolation liners: Nitrile rubber is resistant to oils, fuels, and chemicals, making it suitable for applications where exposure to such substances is expected. Nitrile isolation liners offer good resistance to abrasion and provide a protective barrier for pipes.

- Silicone isolation liners: Silicone rubber is known for its high-temperature resistance and flexibility. Silicone liners are used in applications where elevated temperatures are a concern, providing thermal stability along with vibration damping.

- Natural isolation liners: Natural rubber provides good resilience and abrasion resistance. It is a cost-effective option for general-purpose applications where exposure to harsh chemicals or extreme temperatures is not a major concern.

The choice of rubber liner depends on the specific requirements of the application, including the type of piping system, environmental conditions, and the potential exposure to chemicals or extreme temperatures. Using the appropriate rubber liner helps maximize the effectiveness of U-Bolts in providing support while minimizing the risk of damage to the supported pipes. For more information on RedLineIPS rubber liner materials visit our liners page here.

RedLineIPS U-Bolts epitomize stability and support in petrochemical piping systems. With an innovative design, diverse applications, and robust materials, our U-Bolts elevate piping system performance and stability. Contact Cogbill today for expert guidance and customized solutions tailored to your unique requirements.

FAQ's

Typical Queries and Information

What is a U-bolt and what does it do?

A U-bolt is a U-shaped fastener with threaded legs that wraps around a pipe and bolts to a base or bracket. It helps secure the line in position, maintain alignment, and provide restraint at the support point.

How are U-bolts used in industrial piping systems?

U-bolts are used for supports, hangers, guides, and general restraint—holding piping on beams or brackets, helping control vibration, and keeping lines on their intended routing in pipe racks and structures.

Can a U-bolt act as an anchor or a guide?

Yes. When tightened to clamp the pipe firmly with no clearance, a U-bolt can act as an anchor (restricting movement). When installed with a controlled clearance and the support detail is set up to allow axial sliding, it can act as a guide (allowing axial movement while limiting lateral/vertical movement).

What materials and finishes are U-bolts available in?

U-bolts are commonly supplied in carbon steel, stainless steel (such as 304/316), and other project-specified alloys. Finishes can include bare/mill finish, hot-dip galvanized, or coated/painted systems as required by the project and service environment.

Can U-bolts be supplied with isolation liners?

Yes. U-bolts can be supplied with rubber or elastomer liners (such as neoprene, EPDM, nitrile, or silicone) to cushion the pipe, reduce noise and vibration, and minimize metal-to-metal contact that can damage coatings and contribute to corrosion at the clamp point.