Non-Adjustable Pipe Supports

- Home

- Metallic Piping Supports

- Non-Adjustable Pipe Supports

Metallic Piping Supports

Photo Gallery

Let’s Start Work

Together

What is a Non-Adjustable Pipe Support?

Non-adjustable pipe supports, or rigid pipe supports, are essential fixtures used to securely anchor and support pipes in a fixed position within piping systems. Constructed from robust metals, these supports provide a stable and reliable base for piping systems and pipelines, ensuring alignment and minimizing movement under static conditions where adjustments are not required post-installation.

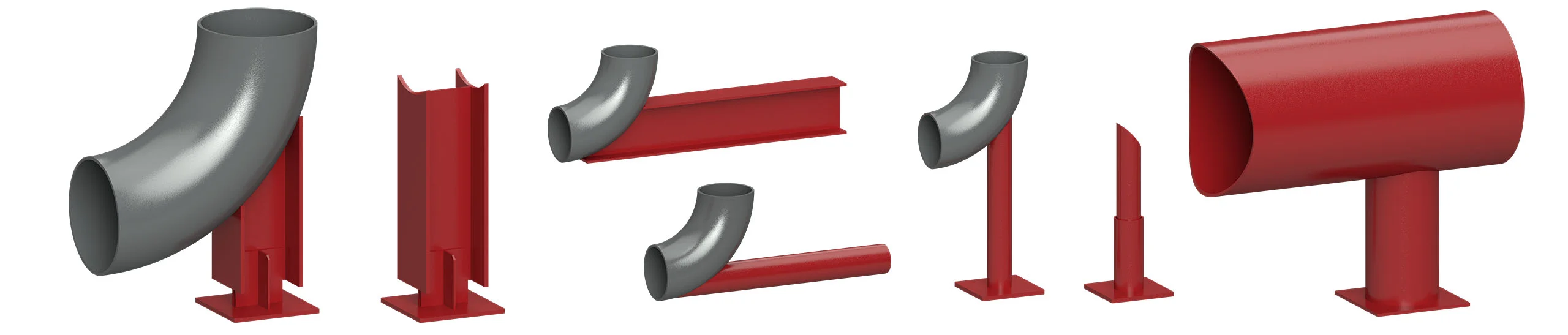

RedLineIPS Non-Adjustable Pipe Supports

As a custom metal fabrication company, Cogbill can manufacture an infinite variety of sizes, designs and configurations of RedLineIPS piping supports and accessories. Our experienced managers, skilled fabricators and certified welders build to customer design, with superior quality and on time delivery, while accommodating customer needs and project changes. Full quality documentation is a standard offering with every project.

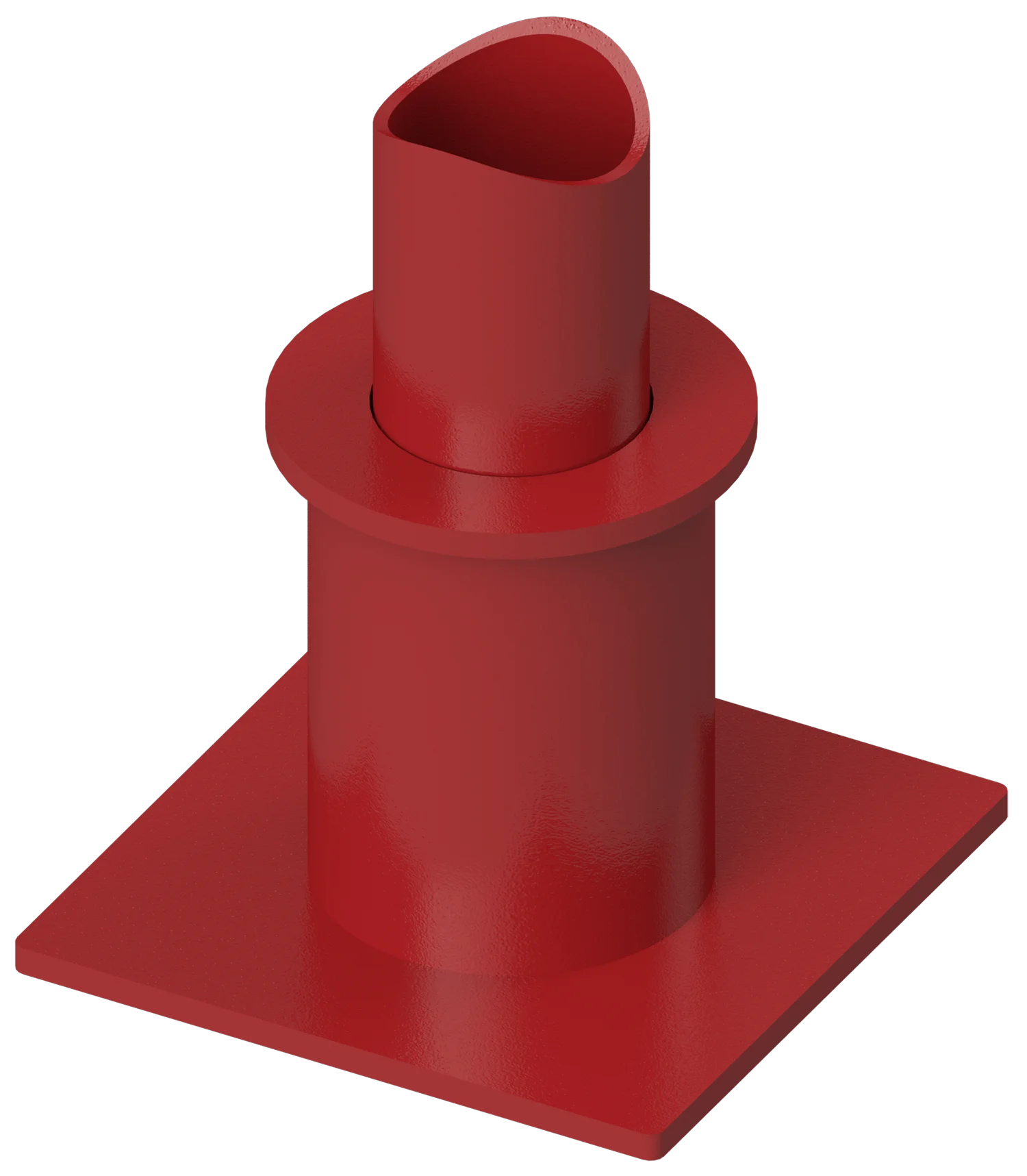

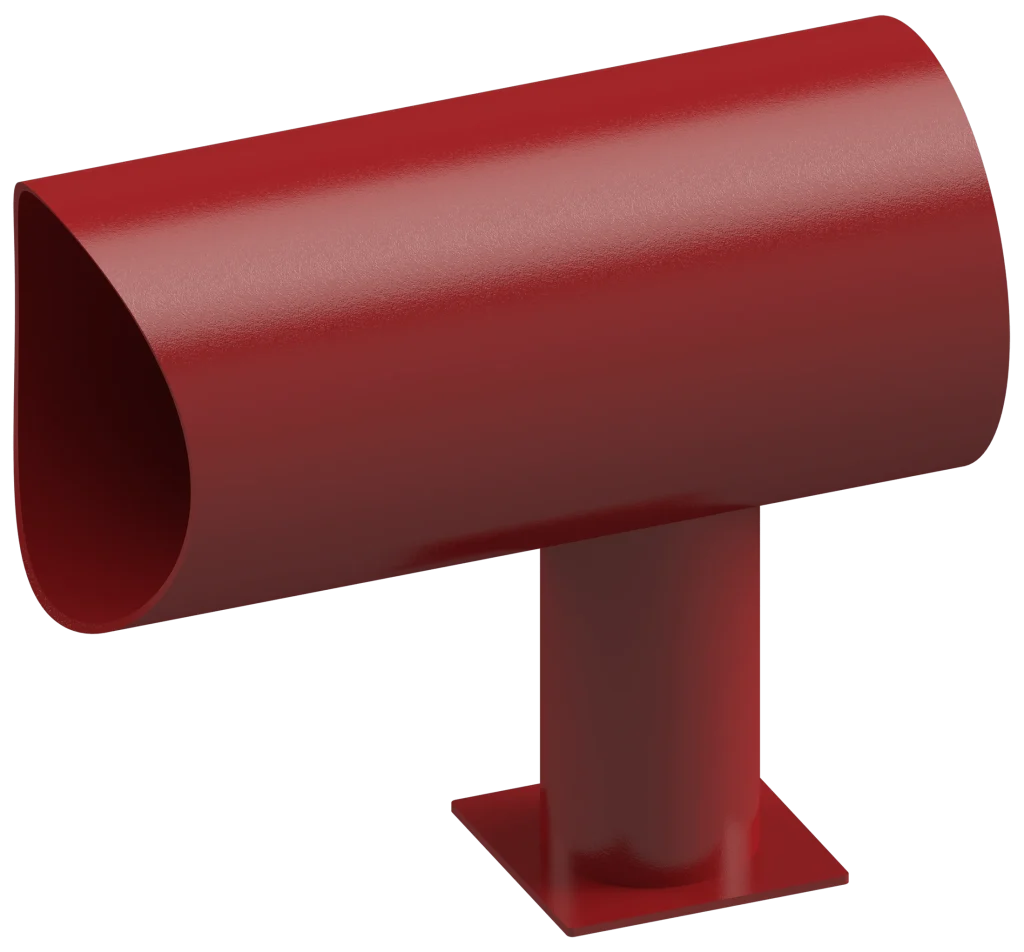

RedLineIPS Pipe Stanchions

Pipe stanchions, indispensable components in industrial piping systems, are vertical, can be non-adjustable or allow one-time field-adjustment. These pipe supports are designed to provide structural stability. As rigid, upright columns, they effectively prevent excessive movement or sagging of pipes, particularly crucial in applications demanding vertical pipe support, such as often the case is in petrochemical and gas piping systems.

Pipe stanchions can be either welded to a pipe, or non-welded utilizing a pipe clamping mechanism, such as U-Bolts or clamps, for easy field installation. The one-time adjustable variety offers flexibility for field fine tuning of proper height and to accommodate variations in project specifications.

Components of RedLineIPS Pipe Stanchions

- Base section for foundation attachment. This can be a base plate with the following variations: Plain base steel plate, base plates with holes or slots, or an additional slide plate assembly underneath to allow limited movement in order to accommodate minor vibrations, expansion or contraction caused by temperature variations, or limited overall system movements. For more information on our slide plate offerings please click here.

- An upright column section providing vertical support, which can either be a pipe, a structural beam, or other fabricated sections.

- A top section for securing the pipe in place. This can be a coped pipe to allow a pipe run or a pipe elbow, usually welded to the pipe being supported. Optional clamps or U-Bolts can also be used for a non-welded stanchion.

RedLineIPS Pipe Stanchions Features and Benefits

- Material Versatility: Adaptable to diverse material requirements, pipe stanchions are crafted from carbon, stainless, and alloy steel, ensuring resilience in harsh industrial conditions.

- Welding Options: Our pipe supports offer convenient welding options, allowing for attachment to pipes either in controlled shop environments or on-site in the field, providing flexibility in installation.

- One-Time Adjustability: Certain RedLineIPS pipe stanchions provide a unique one-time adjustment opportunity, particularly beneficial for accommodating sloped grades and ensuring precise alignment.

- Efficient Installation: Engineered for easy installation, pipe stanchion supports are custom-fabricated to seamlessly fit with pipes, contributing to efficient and reliable support within the piping system.

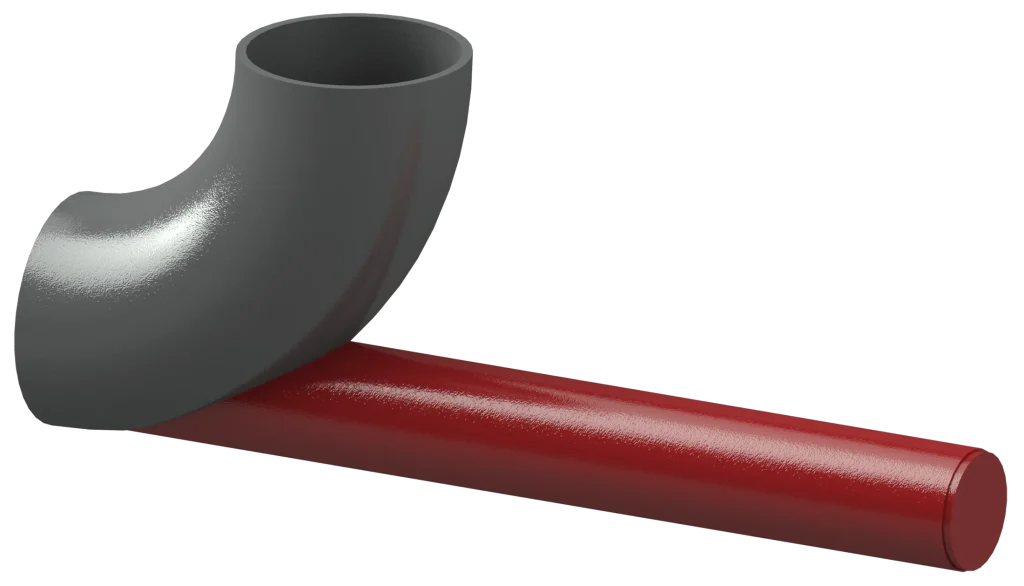

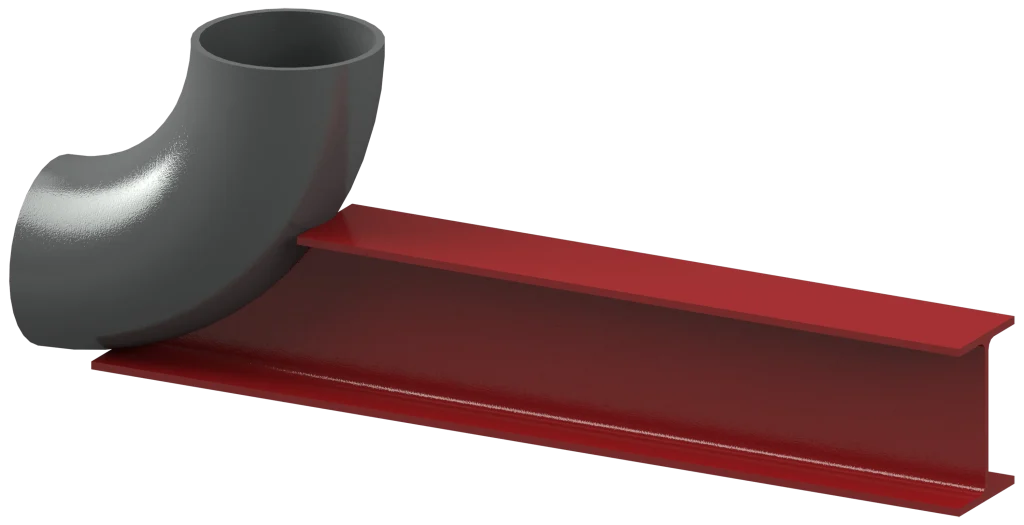

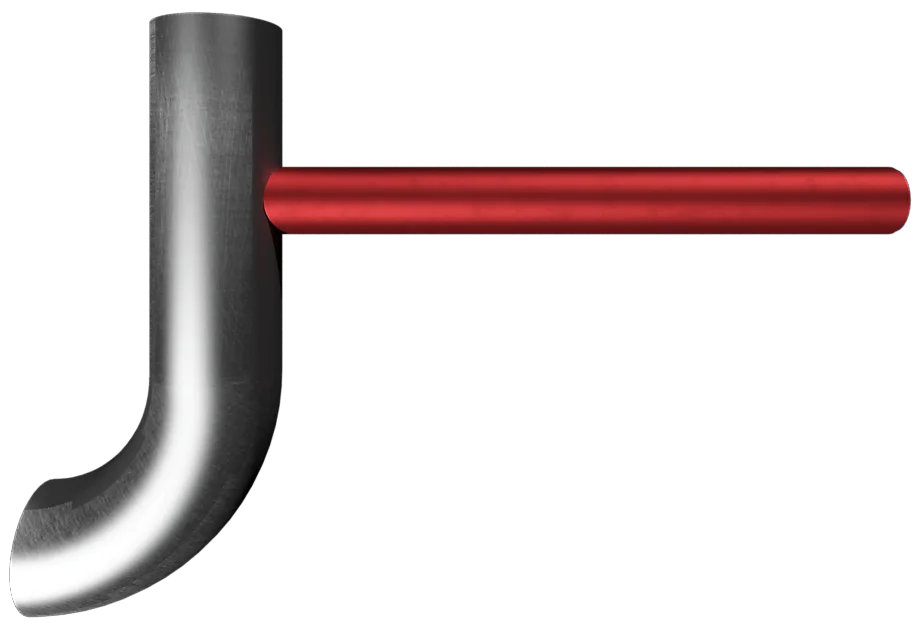

RedLineIPS Dummy Legs

A dummy leg is a non-adjustable support extension specifically designed to offer support to an elbow pipe that extends beyond its vertical supports, leaving it vulnerable and inadequately supported. To address this weakness, the dummy leg horizontally connects the pipe elbow to a nearby structure, ensuring that necessary support is provided. This component, either a coped beam or pipe segment, is usually sized to be the same as or smaller than the pipe it supports, and is welded to the elbow of the pipe run. This welded arrangement serves as a sturdy support, fortifying potential weak points in the overall piping system.

RedLineIPS Dummy Leg Features

- Critical Support at Unprotected Elbows: The primary and critical role of a dummy leg is to provide support at unprotected elbows within a piping system. It addresses situations where elbows extend beyond their supports, ensuring added stability and averting potential hazards.

- Pressure Absorption and Gravity Resistance: Strategically welded to the back of pipe elbows, dummy legs excel at absorbing pressure in high-stress areas. They counteract the effects of gravity, preventing potential joint separation by offering an additional support point.

- Enhanced Safety Measures: By supporting the extension of elbow joints and fortifying them with additional support, dummy legs significantly contribute to a safer working environment.

- They play a crucial role in mitigating potential dangers associated with high-pressure points and gravitational forces.

Dummy Leg Material Composition

RedLineIPS heavy-duty dummy legs are typically fabricated from materials identical to the main pipe, ensuring seamless compatibility and uniformity in the system, as well as mitigating the issue of corrosion. Common materials include carbon steel, stainless steel, or alloy steel, selected for their strength, durability, and resistance to the specific conditions encountered in the piping environment, especially at coastal and offshore facilities.

RedLineIPS dummy legs can be custom manufactured in a variety of configurations and designs to suit specific needs and environmental conditions. They can also be coupled with a variety of piping attachments to create endless configurations that suit the majority of needs. Call us today for more information.

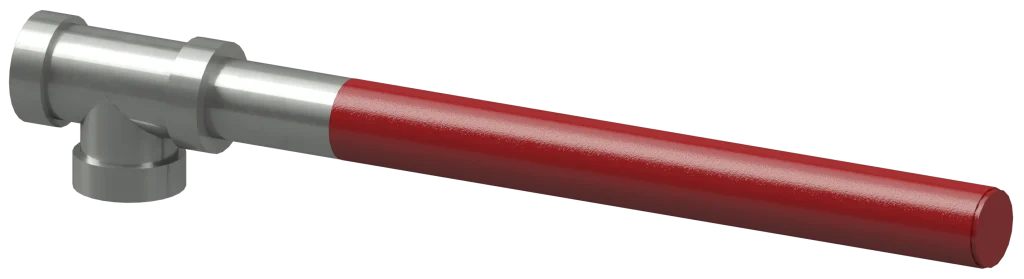

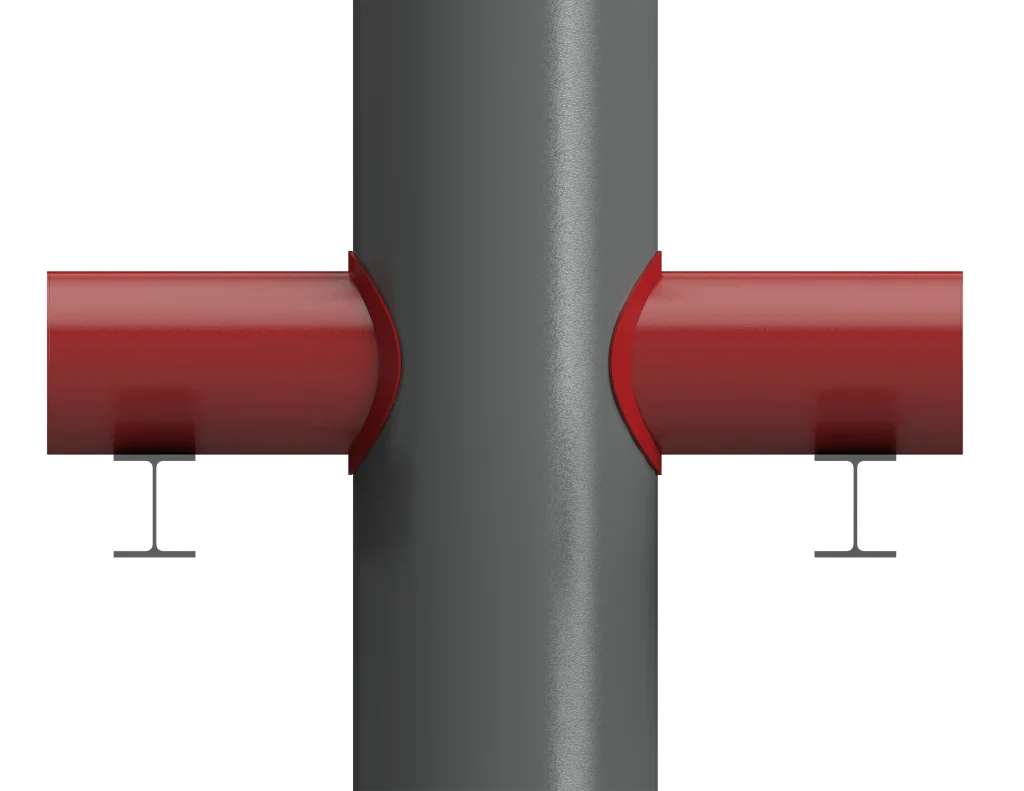

RedLineIPS Trunnions

RedLineIPS Trunnions, meticulously crafted by Cogbill, are non-adjustable pipe supports utilizing horizontal, stationary shafts or pivot points. Trunnions, used in pairs or single pieces, are attached or welded to a vertical pipe run, sometimes with the use of a reinforcing pad for a more secured attachment, securing it to a nearby supporting structure. RedLineIPS Trunnions offer unparalleled support while permitting controlled movement through the use of spring hangers, for example.

The primary purpose of trunnions is to enhance the stability and load-bearing capacity of vertical piping sections within a piping system. By strategically adding support through trunnions, these components prevent the loss of stability in vertical piping, contributing to the overall structural integrity of the piping system.

RedLineIPS Trunnion Material Composition

The material of RedLineIPS Trunnions is carefully selected to ensure compatibility with the parent pipe material. Commonly crafted from metals such as stainless steel, carbon steel, or other alloys, depending on specific application requirements.

Trunnion Key Characteristics

Support and Limited Rotation

- RedLineIPS Trunnions are designed to deliver robust support while permitting controlled vertical and/or horizontal movement.

- Their application is critical in situations where controlled pipe movement is necessary, addressing challenges such as thermal expansion or contraction.

Size Variation and Attachment

- As part of the RedLineIPS brand, these trunnions are meticulously crafted to be one or more sizes smaller than the parent pipe, ensuring compatibility and effective reinforcement.

Ease of Construction and Use

- RedLineIPS Trunnions, bearing the mark of Cogbill, find wide usage in the piping industry due to their ease of construction and erection.

- While easy to use, it's essential to note that the load-bearing capacity of RedLineIPS Trunnion supports may differ from civil structural supports.

Critical Considerations for Pipe Stress Engineers

- Pipe stress engineers, especially when working with trunnions, must meticulously examine weld points from a failure viewpoint.

- The investigation of the trunnion's ability to carry piping loads, especially tangential and longitudinal loads and corresponding momentums, is a crucial aspect of ensuring structural integrity.

Why RedLineIPS Supports

RedLineIPS non-adjustable pipe supports are designed for durability and reliability in the harshest industrial environments. With stringent quality assurance and adherence to AWS D1.1 and ASME Section IX welding standards, our products ensure superior performance. Manufactured in the U.S.A., we guarantee on-time delivery to meet your project deadlines. For more information, contact us today.

FAQ's

Typical Queries and Information

What is a non-adjustable pipe support?

A non-adjustable pipe support (rigid support) is a fixed-height support that holds a pipe at a set elevation without any built-in height adjustment. These supports provide stable elevation, alignment, and load transfer in locations where the support height is defined by the project design and is not expected to change after installation.

When would I use a non-adjustable support instead of an adjustable one?

Non-adjustable supports are commonly used as an economical option where pipe elevations and support points are already “locked in” by the design and field fit-up is straightforward—such as final runs, repeated standard details, or locations unlikely to be modified. Adjustable supports are more typical where the engineer anticipates field fit-up, settlement, or future reroutes; the project’s engineer of record ultimately decides which support type is appropriate for each line.

What types of non-adjustable supports does Cogbill manufacture?

Cogbill manufactures a range of RedLineIPS non-adjustable supports, including pipe stanchions, dummy legs, and trunnions, along with project-specific variants built to customer drawings and specifications. Depending on the design, these supports can be welded to the pipe or used with clamps and U-bolts, providing rigid, fixed-height support where adjustability is not required.

What is a pipe stanchion in an industrial piping system?

A pipe stanchion is a vertical, rigid support that carries the weight of a pipe run or elbow down to a foundation, structural steel, or concrete. RedLineIPS pipe stanchions, manufactured by Cogbill, are typically fabricated from carbon, stainless, or alloy steel and may be welded directly to the pipe or used with U-bolts and clamps. Some designs allow a one-time field adjustment during installation, after which the support functions as a fixed, non-adjustable column.

What is a dummy leg pipe support and when is it used?

A dummy leg is a non-adjustable support extension, usually a short piece of pipe or structural section welded to the back of an elbow, that transfers the elbow’s load to nearby steel or concrete. It is used where an elbow extends beyond its vertical supports and would otherwise be under-supported. By adding a dummy leg, the elbow gains an extra support point that helps resist gravity and pressure loads, improving the overall stability of the piping system.