Pipe Hangers

Pipe hangers are components designed to support and secure pipes from above, maintaining proper alignment while allowing for movement due to thermal expansion and mechanical forces.

- Home

- Metallic Piping Supports

- Pipe Hangers

Metallic Piping Supports

Photo Gallery

Let’s Start Work

Together

What is a Pipe Hanger & Hardware?

Pipe hangers and hardware refer to a range of components designed to support and secure piping systems from above within various installations, such as industrial, commercial, and residential buildings. These components are crucial for maintaining the integrity of the piping system and efficient fluid flow, ensuring that pipes are held firmly in place and with the proper alignment, yet allowing for some degree of movement resulting from thermal expansion, contraction, and other mechanical forces.

This image is interactive. Click on any red marker for more information.

1 of 4Beam Clamp

2 of 4All Threaded Rod

3 of 4Clevis Hanger

4 of 4RedLineIPS Pipe Hanger Benefits

RedLineIPS pipe hangers, manufactured and supplied by Cogbill Construction, play a crucial role in industrial piping systems by connecting pipes to structural elements such as beams, columns, or walls. They serve various functions, including:

- Support and Suspension: Pipe hangers provide essential support, counteracting gravitational forces to prevent sagging or misalignment of pipes, ensuring smooth fluid and gas flow.

- Vibration & Noise Control: Hangers can help dampen vibration and noise if lined with the proper rubber liner material, reducing the risk of damage to pipes, connections, and adjacent structures, vital for maintaining piping system integrity in dynamic environments.

- Mitigate Thermal Expansion and Contraction: Accommodating temperature-induced movements, pipe hangers prevent stress on pipes, preserving their structural integrity despite expansion and contraction. They ensure that pipes remain in their intended positions even as they expand and contract due to temperature changes.

- Alignment: Maintaining proper pipe alignment is crucial for efficient and safe operation, with hangers ensuring pipes remain in the correct position to prevent flow restrictions and leaks. Misaligned pipes can lead to flow restrictions, leaks, and potential damage to the pipes themselves.

- Stress Prevention: By distributing weight and loads evenly, pipe hangers protect pipes, connections and supporting structures from undue stress, preventing premature wear and damage.

- Longevity and Reliability: Providing consistent and stable support, pipe hangers contribute to system longevity, minimizing maintenance needs and ensuring prolonged functionality.

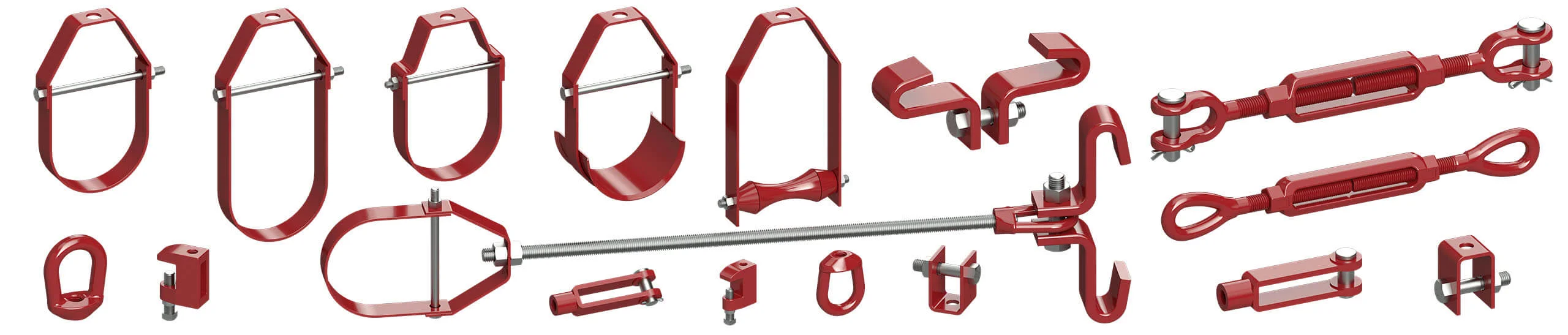

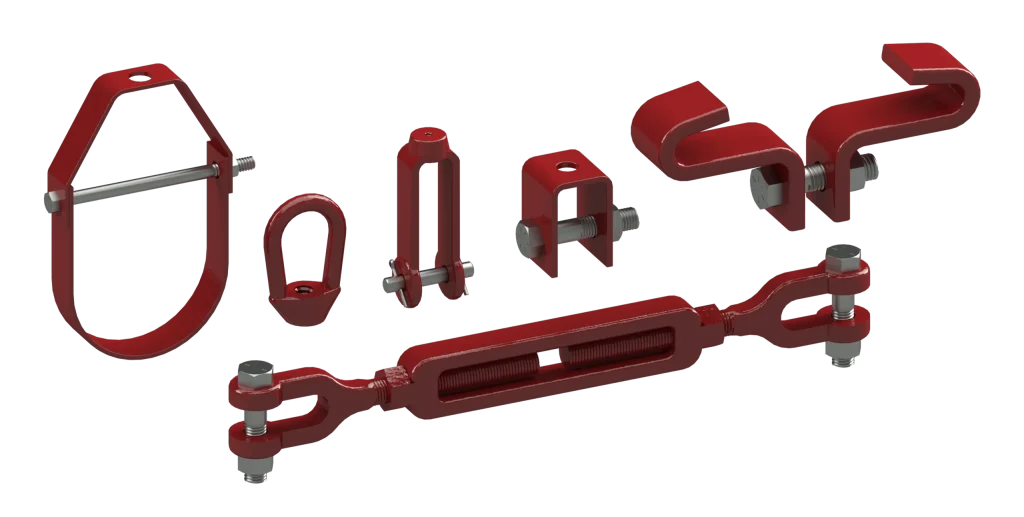

Components of RedLineIPS Pipe Hangers

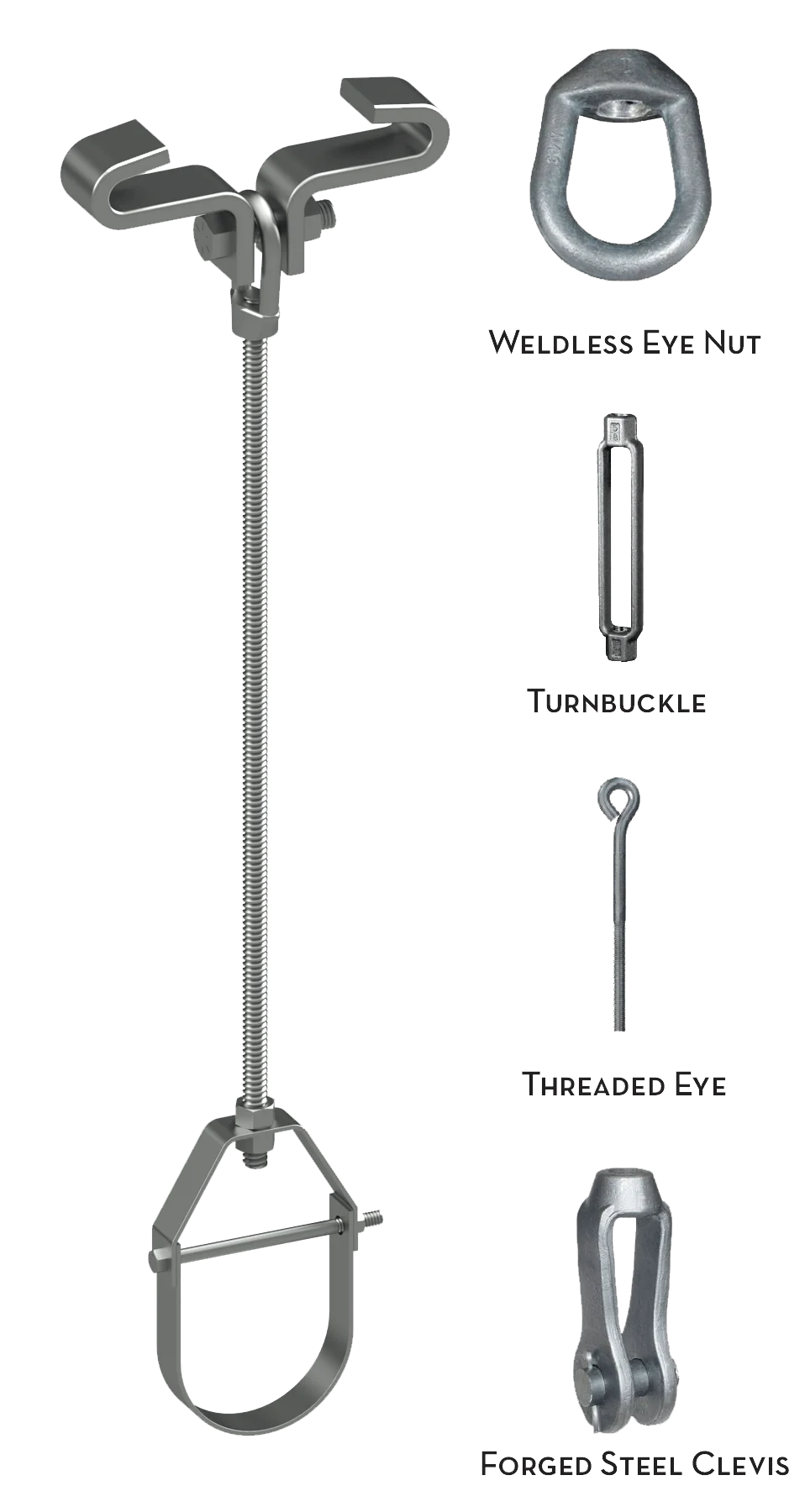

A pipe hanger typically comprises three main components, each serving a distinct purpose, along with various commonly used configurations.

Should you require more detailed information on specific component types for larger piping lines or any other configurations, please don’t hesitate to contact us.

Structural Attachment

The primary function of the structural attachment component is to anchor overhead and support both the pipe hanger and the pipe it carries. Anchoring points may vary, but the most commonly utilized types include steel beams, concrete beams/structures, and vertical columns. Attachment to these structures can be achieved using the following methods:

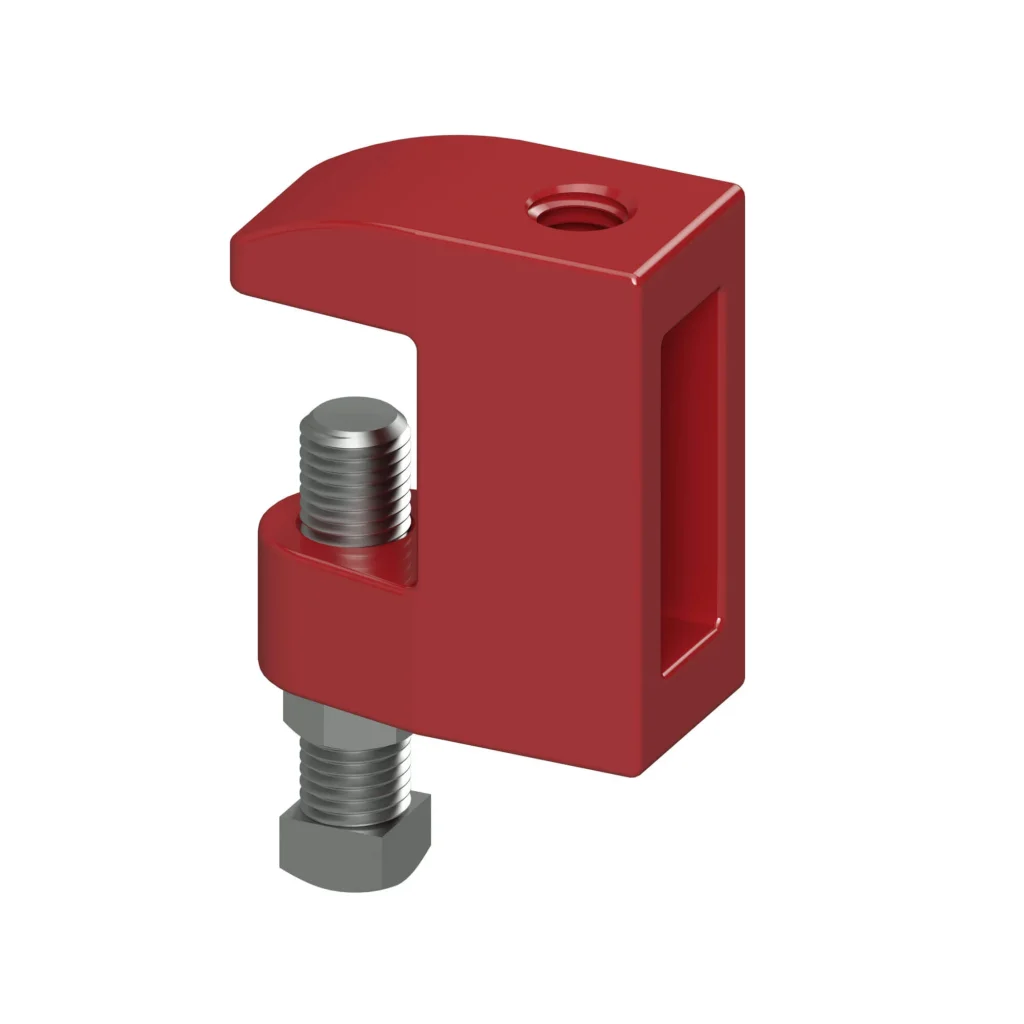

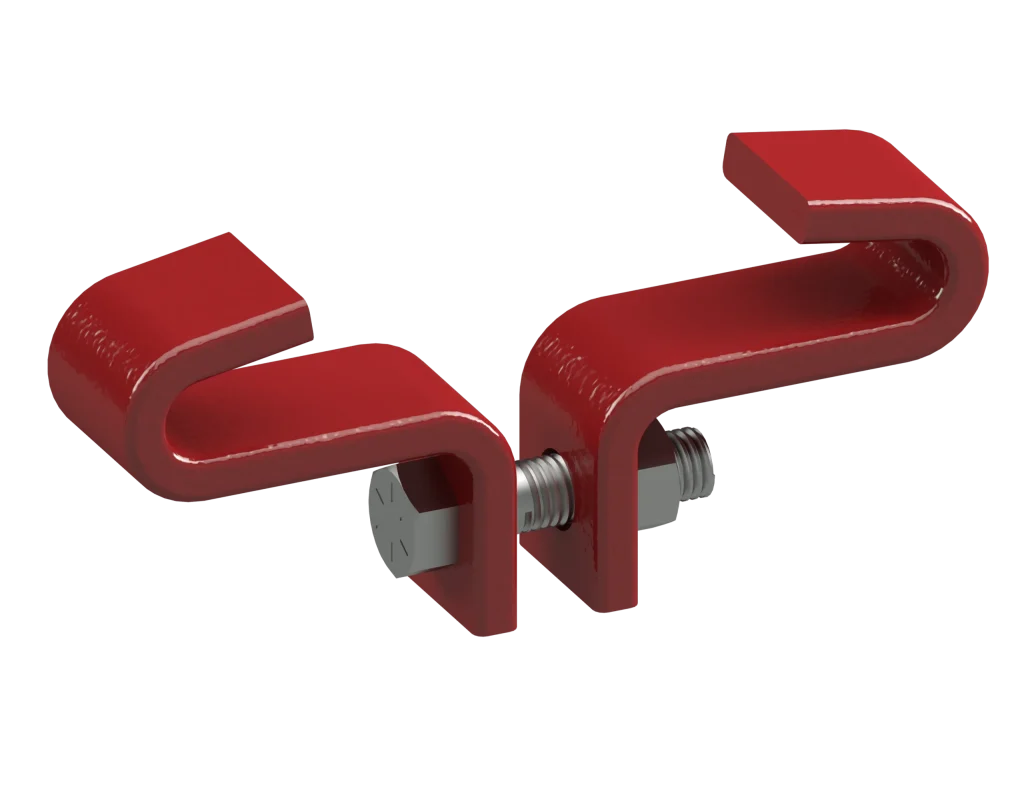

Beam Clamps

Beam clamps are commonly used to attach pipe hangers to steel beams. They come in different types, each serving specific purposes, including:

- Standard C-Clamps: These clamps attach to the side of a steel beam. They typically feature one bolt for fastening to the beam, with the opposite side having a threaded opening for a specific-sized threaded rod to attach into.

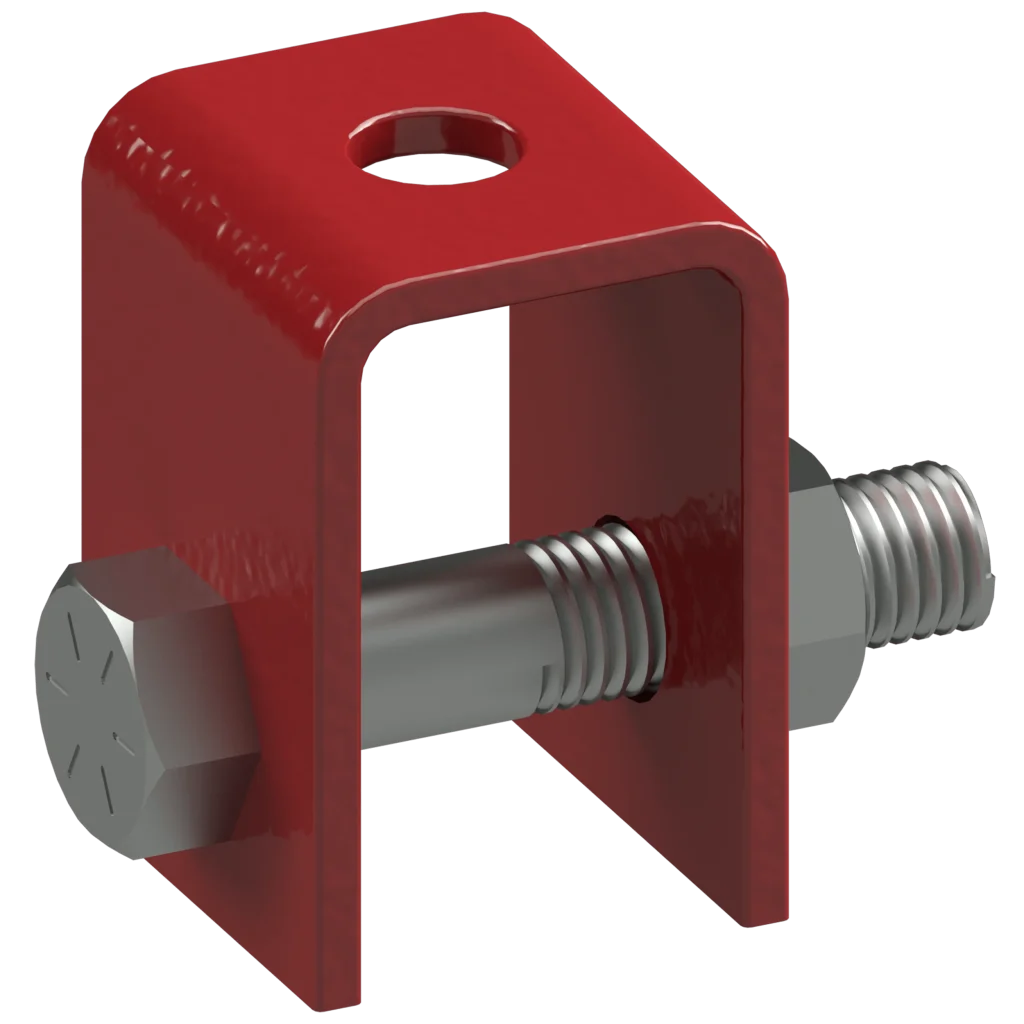

- Standard Duty Beam Clamp/Heavy Duty Beam Clamp: These clamps fasten to both sides of the support beam. They feature a centered bolt that passes through the hardware at the end of the specified rod included in the assembly.

Field-Welded Attachments

Field-welded attachments are components welded onto support beams or other approved steel structures. They come in different types, each serving specific purposes, including:

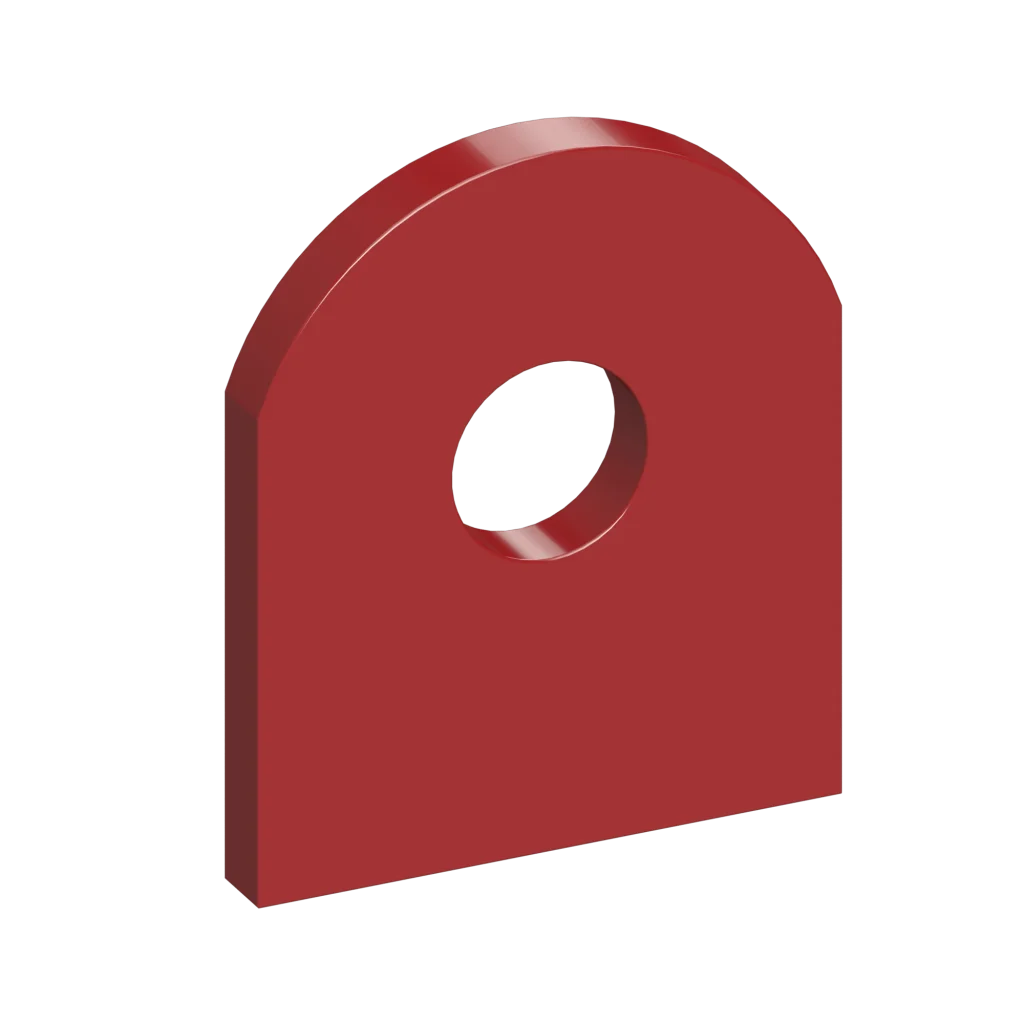

- Short/Long Welding Lugs: These are square-shaped steel plates that are field-welded onto a support beam or another area of approved steel structure. At the end of the steel lug plate, there is a predrilled hole where a steel clevis can be attached.

- Welded Beam Attachments: These U-shaped components, also called “Hanger Clevis Bracket”, are made from steel and can be welded to the bottom or side of a beam. They provide a designated area to secure a steel clevis.

Concrete & Wall Anchoring

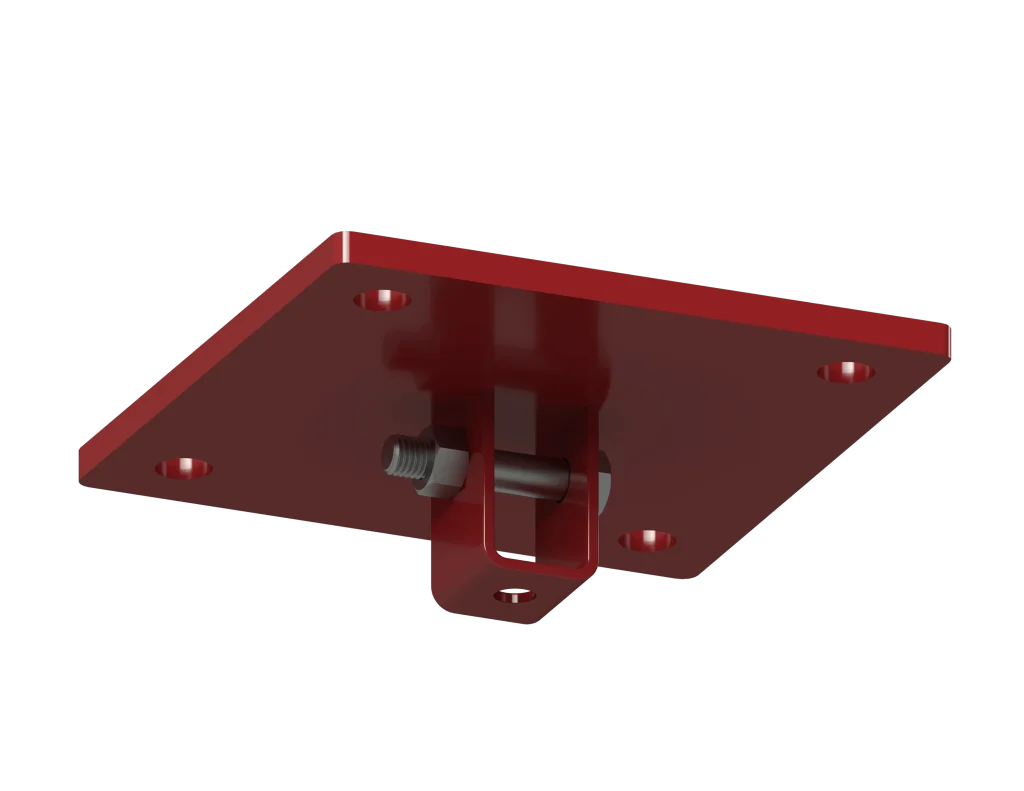

- Anchor Plates: Concrete anchor plates consist of a square section of steel plate with a pre-welded attachment section for fastening a steel clevis. They also feature multiple holes for the use of concrete anchor bolts or lag screws to secure the plate overhead.

- Column Steel Brackets: These brackets are welded steel "L" shapes with two holes on one side intended for mounting to the wall or column. The other side features a single hole at the end designated for the top end of a hanger rod.

RedLineIPS Hardware & Rods

These components play a crucial role in determining the distance between the structural attachment and the hanger mount. They are often adjustable, providing customers with the flexibility to adjust both the height and tension of the designated support. While hardware components are typically used to connect the structural attachment and hanger mount to the rod, they are not always necessary. Let’s break down the most commonly used rods and hardware.

Hardware

- Eye Nuts: An eye nut is a durable hardware component, usually made of materials like steel, designed to support substantial weight. It features a looped head for attachment and a threaded shank for secure fastening. They are also treated for corrosion resistance, making them suitable for various industrial environments.

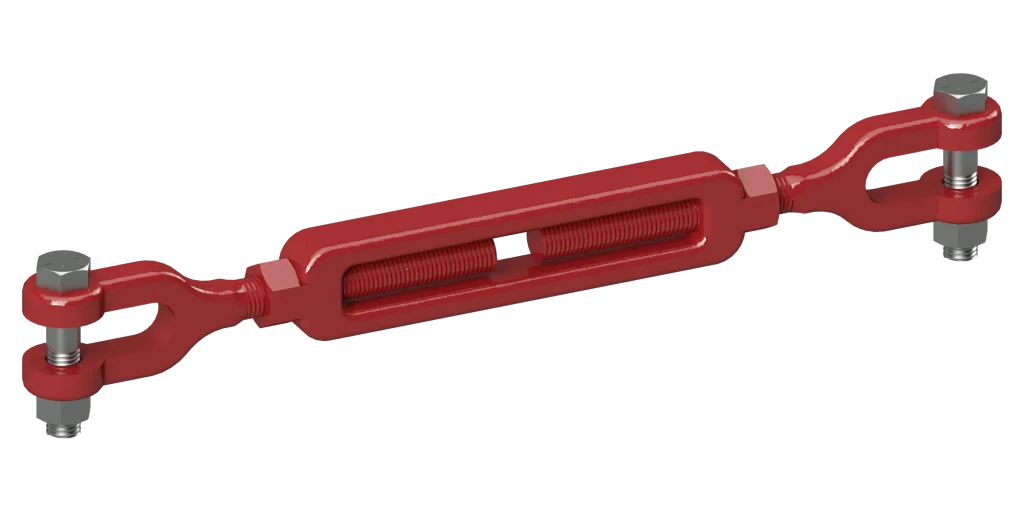

- Turnbuckles: Adjustable, strength-rated components designed for tensioning and stabilizing piping systems. Typically manufactured with forged steel, they consist of a central body with threaded end fittings, allowing for precise adjustments. These turnbuckles are vital in environments where load balance and alignment are critical.

Threaded Rods

- All Threaded Rod: Typically made from steel, these rods feature continuous threading along their entire length, enabling easy customization and adjustment. They play a crucial role in the stability and alignment of piping systems and are commonly crafted from galvanized carbon steel or stainless steel for added durability.

- Machine Threaded Rod: Crafted from high-strength steel, they feature machine-cut threads along each end of the rod for consistent and reliable These rods are ideal for ensuring the structural integrity and alignment of pipe installations.

Hanger Mount

- Steel Clevises: Robust components engineered to securely support and stabilize pipes. They are designed to bear significant weight and withstand industrial demands. Clevises typically feature a U-shaped end with holes for bolt or pin attachment, ensuring a reliable connection.

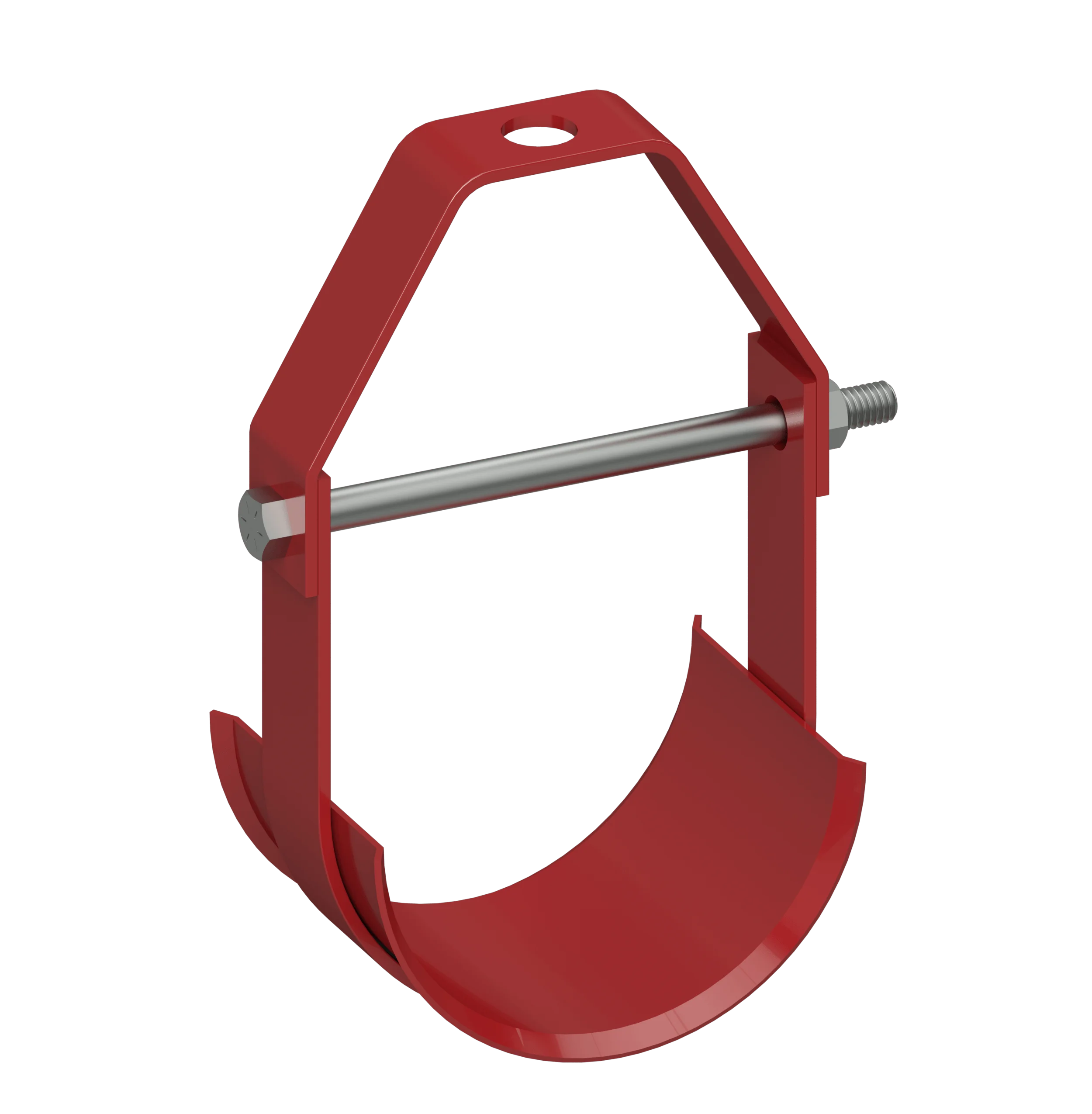

- Elongated Clevis Hanger Mounts: Specifically designed for insulated pipes, these mounts function similarly to clevis hanger mounts, allowing for lateral or axial movement.

- Clevis Hanger Mount with Insulation Shield: Similar to standard clevis hanger mounts but equipped with an insulation shield for use with insulated pipes. They facilitate lateral or axial movement while providing insulation protection.

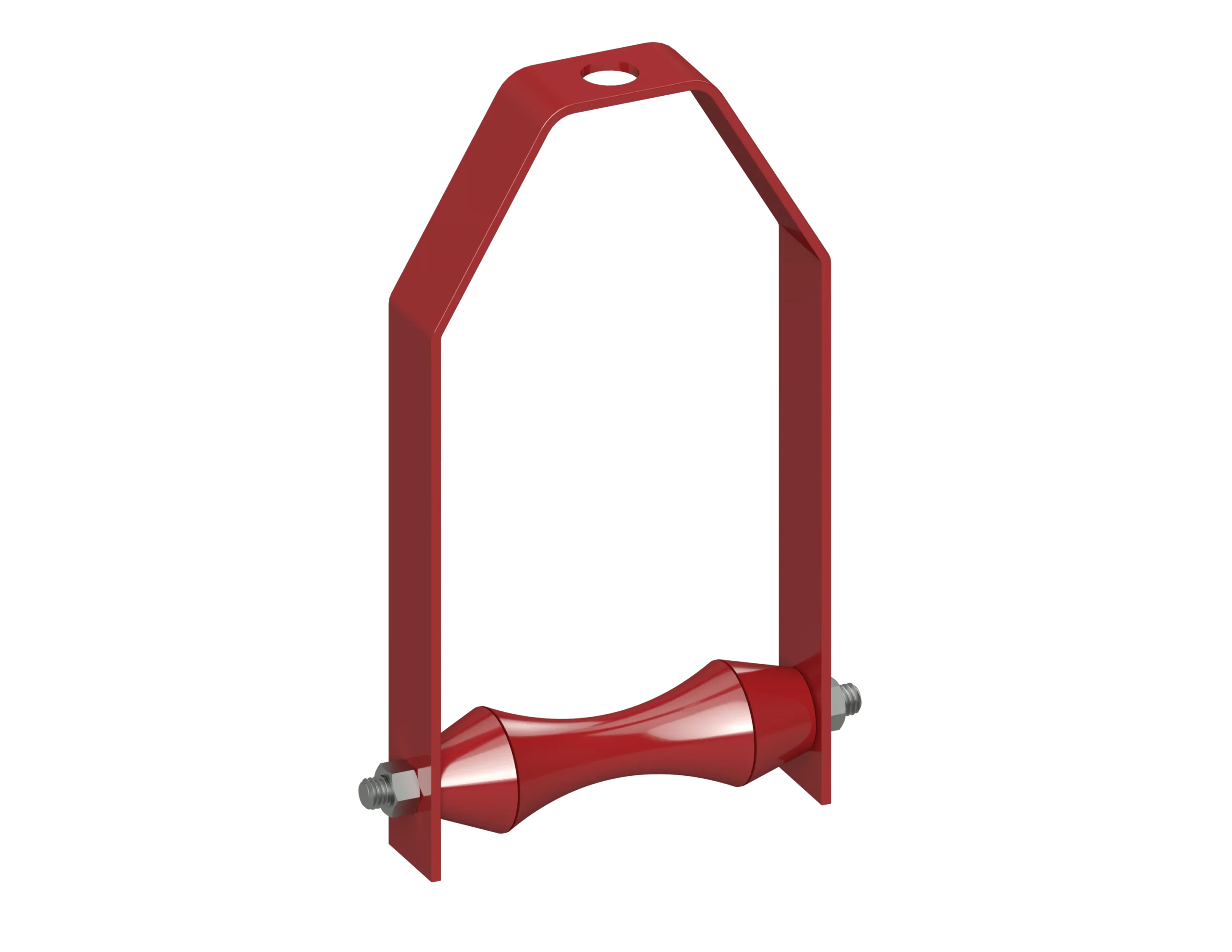

- Roller Hangers: Utilized for pipe runs experiencing thermal expansion and contraction, these hangers consist of a metal frame with a rotating cylindrical roller. The pipe rests on the roller, allowing movement in any direction.

Pipe Hangers Factors to Consider

- Pipe Characteristics: Consider the size, material, and schedule of the pipes.

- Contents: Take into account the pressure, temperature, weight, and flow rate of the contents.

- Piping Layout: Consider the layout, configuration, and direction of the pipes.

- Environmental Conditions: Evaluate the environmental conditions and hazards of the facility.

- Compliance: Adhere to industry standards and regulations.

RedLineIPS Pipe Hangers are manufactured in the USA using a variety of materials according to high quality standards. For standard or custom solutions contacts us for free consultation. Our hangers and hardware components ship worldwide. Contact us today for more information.

FAQ's

Typical Queries and Information

What is a pipe hanger?

A pipe hanger is a support component that suspends piping from above, tying it into beams, concrete, or columns so the line stays in position while still being able to move with thermal expansion, contraction, and mechanical loads. Instead of resting on steel below, the pipe is carried from the overhead structure.

What types of pipe hangers does Cogbill manufacture?

Cogbill manufactures a range of RedLineIPS hanger assemblies to customer drawings and specifications. Typical configurations include standard clevis hangers, elongated clevis hangers for insulated pipes, clevis hangers with insulation shields, and roller hangers for high-movement runs. Components are usually fabricated from carbon steel or stainless steel, with mill finish, hot-dip galvanized (HDG), or shop-painted coatings supplied per project requirements.

What are the main components of a typical RedLineIPS pipe hanger assembly?

Most hanger assemblies combine three elements: a structural attachment (such as a beam clamp, welded lug, anchor plate, or column bracket), threaded hardware (rod, nuts, eye nuts, turnbuckles, etc.), and a hanger mount like a clevis or roller hanger. The attachment connects to the structure, the rod sets the elevation, and the hanger mount interfaces with the pipe or insulation system.

How do pipe hangers help manage thermal expansion, contraction, vibration, and noise?

When detailed correctly on the drawings, pipe hangers allow the line to move axially—and in some cases laterally—as temperature changes, rather than forcing movement into rigid connections or equipment nozzles. Where required, Cogbill can fabricate RedLineIPS hanger components with rubber or elastomeric inserts and isolation hardware that help damp vibration and reduce transmitted noise through the support system.

Do RedLineIPS pipe hangers ship as complete assemblies or as loose components?

Cogbill can supply RedLineIPS pipe hangers either as fully packaged assemblies—rods, clamps, and hanger mounts kitted together for repeatable field installs—or as loose components (beam clamps, rods, clevises, rollers) when a project needs more flexibility. The packaging approach follows your BOM and project instructions.