Pipe Shoes

- Home

- Metallic Piping Supports

- Pipe Shoes

Metallic Piping Supports

Photo Gallery

Let’s Start Work

Together

What is a Pipe Shoe?

RedLineIPS Pipe Shoes

- Thermal Protection: Pipe shoes can insulate the pipe from extreme temperatures, either from the process fluid within the pipe or from environmental conditions, thus preventing thermal damage to both the pipe and the support structure.

- Corrosion Prevention: By elevating the pipe, shoe supports help to mitigate corrosion by reducing moisture entrapment and allowing for better air circulation around the pipe.

- Load Distribution: They distribute the weight of the pipe and its contents across a broader area, reducing stress on the pipe and the supporting structure.

- Allowance for Movement: Some pipe shoes are designed to accommodate thermal expansion and contraction of the pipe, as well as other movements, without compromising the integrity of the piping system.

Types of RedLineIPS Pipe Shoes

RedLineIPS pipe shoe supports come in various types, each tailored to specific demands within a piping system. These diverse types of pipe shoes collectively play a pivotal role in enhancing the longevity and efficiency of industrial piping systems by offering tailored support to counteract the myriad challenges they may encounter. Among the types of pipe shoes are:

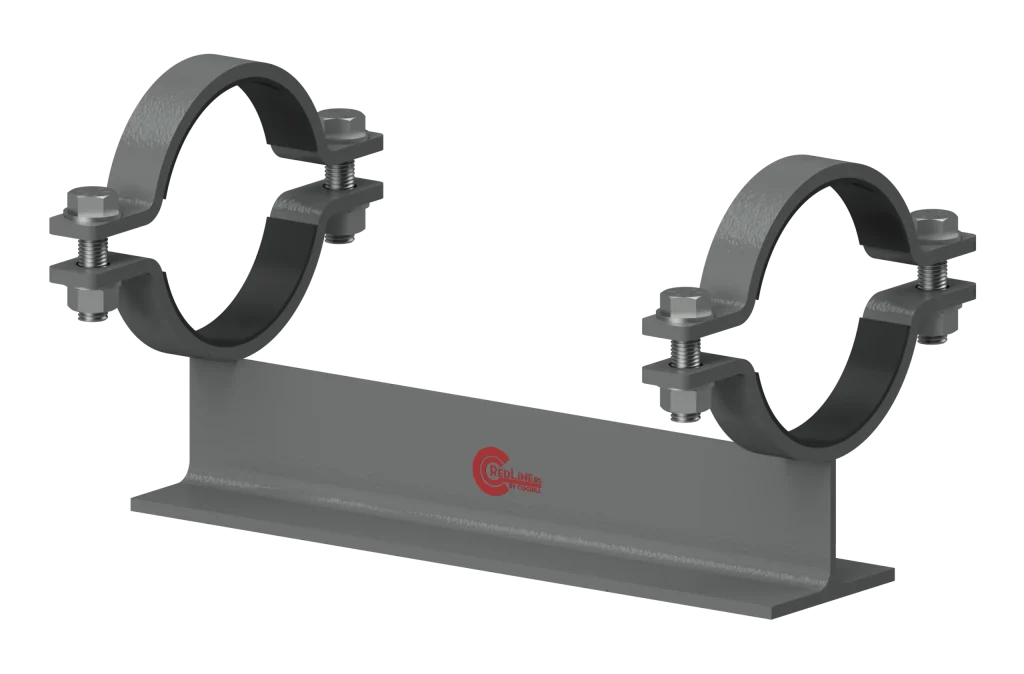

Non-Welded Pipe Shoes: Weld-Free Efficiency

Non-Welded RedLineIPS Pipe Shoes provide a practical solution for supporting piping systems across various industries without the need for welding. These pipe supports are designed for easy attachment using clamps, and are commonly called Clamp-on Pipe Shoes, Clamped-on Pipe Shoes, or Clamped Pipe Shoes. They can also utilize U-Bolts, and are commonly called Bolt-on Pipe Shoes or Bolted Pipe Shoes. This type significantly reduces installation time and avoids the complexities associated with welded supports. For more information about U-Bolts visit our page here.

Key Features of RedLineIPS Non-Welded Pipe Shoes

The key advantage of RedLineIPS Non-Welded Pipe Shoes lies in their simplicity and speed of installation. By circumventing welding, these supports eliminate the need for hot work permits, line shutdown, and specialized labor, leading to lower labor, downtime and operational costs. Their design accommodates a wide range of pipe diameters, offering flexibility across different applications.

Eliminating welding from the installation process not only preserves the pipe’s structural integrity by avoiding heat-affected zones but also enhances workplace safety by reducing fire hazards. These pipe shoes are also easy to inspect and maintain, ensuring the longevity of both the support and the piping system.

RedLineIPS Non-Welded Pipe Shoe Supports usually come with corrosion-resistant liners on the bolts or the clamps so they can mitigate the effects of galvanic and crevice corrosion that cause Corrosion Under Pipe Supports (CUPS). Refer to our liners page here for more details.. This, combined with the reduced need for maintenance and replacements, renders them a cost-effective solution for industrial piping systems.

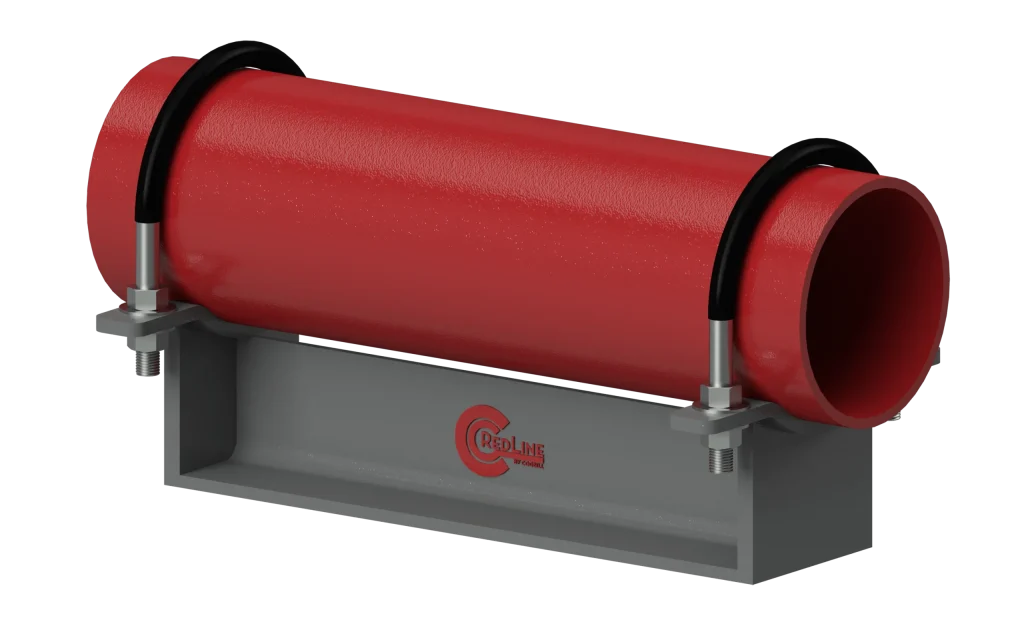

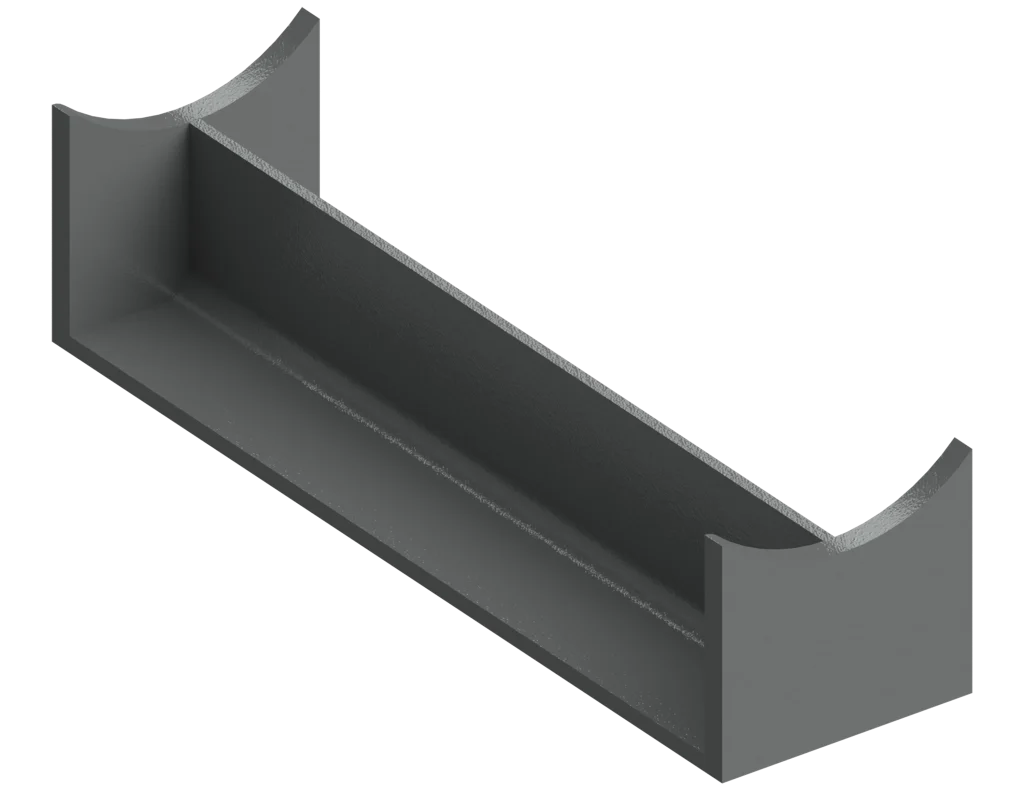

Welded Pipe Shoes: Cost-Effective Supports

Welded pipe shoes are the most cost-effective solution for preserving the integrity of insulated piping systems. These shoe supports not only support the weight of the pipe but also serve as guides, effectively restraining thermal movements in piping systems. Additionally, they can prevent undesirable metal-to-metal contact between uninsulated pipe walls and supporting steel.

Some of RedLineIPS pipe shoes have a flexible design that allows them to be utilized as either welded or non-welded shoes, depending on engineering specifications. Among this type is Saddle Shoes, which can be attached to a pipe using full welds, tack-welding, or without any welding, which would rely on the pipe’s size and weight to remain in place.

Key Features of RedLineIPS Welded Pipe Shoes

- Thermal Movement Control: Welded pipe shoe supports offer reliable control over thermal movements in piping system, reducing the risk of structural damage.

- Material Matching: RedLineIPS Non-Welded Pipe Shoes are directly welded to the pipe wall, ensuring they match the material of your piping system for optimum performance and to reduce the possibility of galvanic corrosion.

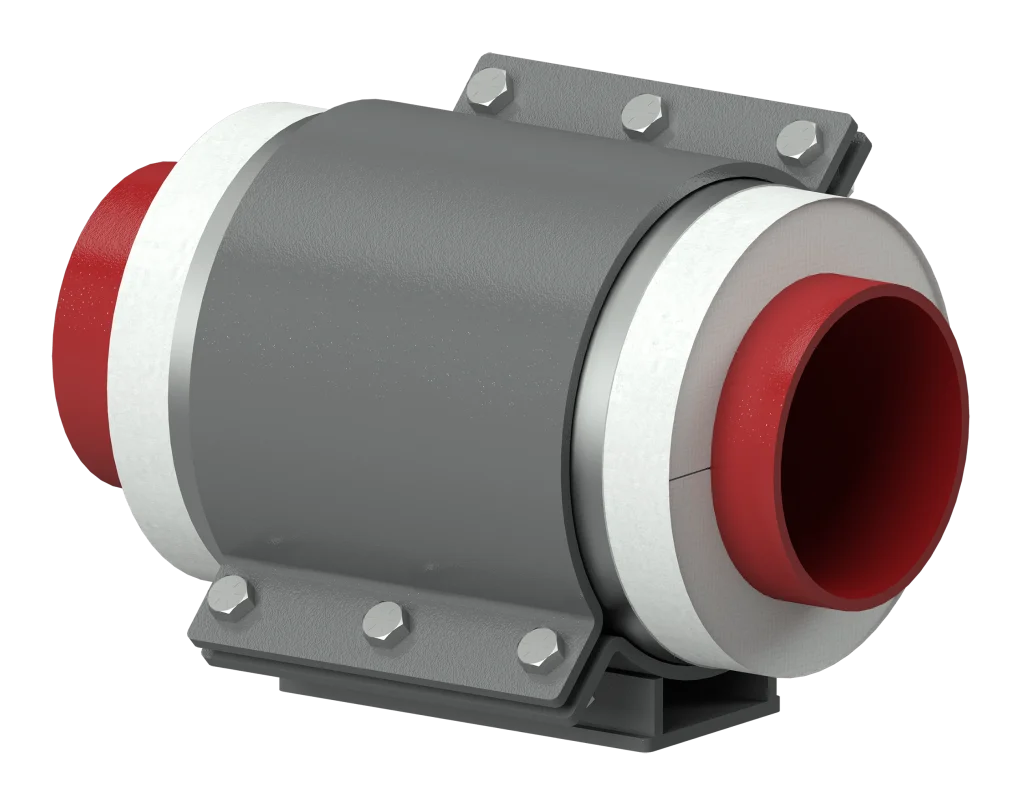

Pre-Insulated Pipe Shoes: Resilience in Extreme Conditions

Key Features of Pre-Insulated Pipe Shoes

- Extreme Temperature Suitability: Pre-insulated pipe shoes are engineered to perform in extreme temperature conditions, ensuring your piping system remains robust in challenging environments.

- Custom Fabrication: Cogbill’s RedLineIPS Pipe Shoes can be tailored to customer specifications, making them an ideal choice for projects with unique requirements.

At Cogbill, we specialize in crafting custom pipe shoe designs, serving markets locally, nationally, and globally for over two decades. Our experienced fabricators, certified welders, and advanced manufacturing processes equip us to meet every pipe support challenge with precision and excellence.

Your piping system deserves the best, and at Cogbill, we ensure it receives precisely that. For more information about our custom-manufactured pipe shoes or for a quote, contact us today.

FAQ's

Typical Queries and Information

What is a pipe shoe?

A pipe shoe is a structural support that elevates the pipe off the steel or concrete, spreading the load and keeping the pipe from sitting directly on the support surface. By lifting the pipe, a shoe helps manage weight, thermal expansion, and movement while reducing wear, coating damage, and moisture traps at the contact point.

What types of pipe shoes does Cogbill manufacture under the RedLineIPS brand?

Cogbill manufactures a range of RedLineIPS pipe shoes, including non-welded (clamp-on/bolt-on) pipe shoes, welded pipe shoes, and pre-insulated “cold shoes” for extreme temperatures. Within those families, Cogbill fabricates various configurations—such as saddle shoes, gusseted shoes, tall shoes, and clamp-on shoes with U-bolts or clamps—built to customer drawings and specifications.

What is the difference between welded and non-welded (clamp-on) pipe shoes?

Welded pipe shoes are welded directly to the pipe and are often the most cost-effective option for many insulated lines, but the pipe and shoe act as one piece—there is no relative axial movement between them. Non-welded (clamp-on or bolt-on) shoes attach with clamps or U-bolts instead of welds, so the pipe can grow and shrink axially through the shoe while the shoe stays landed on the steel. This avoids hot work permits and heat-affected zones and makes weldless shoes especially useful for brownfield work, live lines, and locations where welding is difficult, restricted, or undesirable.

What are pre-insulated (cold) pipe shoes used for?

Pre-insulated, or “cold,” pipe shoes are clamp-on shoes built around high-density polyurethane foam or similar insulation for extreme temperature service, often down to around −300°F (−184°C). They are typically used on LNG lines, cryogenic services, and other cold or high-temperature applications where you must control heat transfer while still supporting and guiding the pipe.

How do RedLineIPS pipe shoes handle thermal movement and corrosion at support points?

Many RedLineIPS pipe shoe designs from Cogbill incorporate slide plates or low-friction interfaces so the pipe can move axially with temperature changes while the shoe carries the load. By elevating the pipe and, in non-welded designs, adding corrosion-resistant isolation liners on clamps, U-bolts, or saddles, these shoes help reduce metal-to-metal contact, minimize moisture entrapment, and manage corrosion under pipe supports (CUPS) at the support point