Shim Block Assembly

- Home

- Metallic Piping Supports

- Shim Block Assembly

Metallic Piping Supports

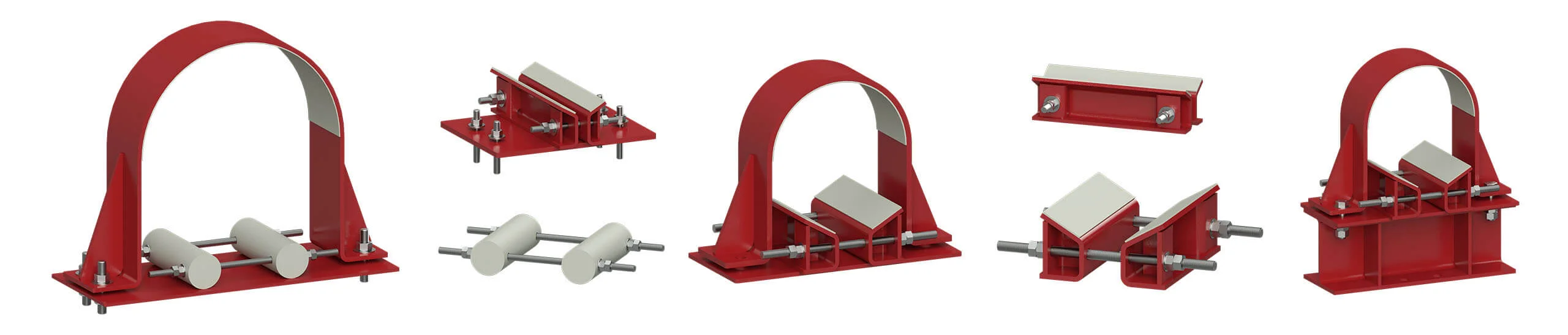

Photo Gallery

Let’s Start Work

Together

What is a Shim Block Assembly?

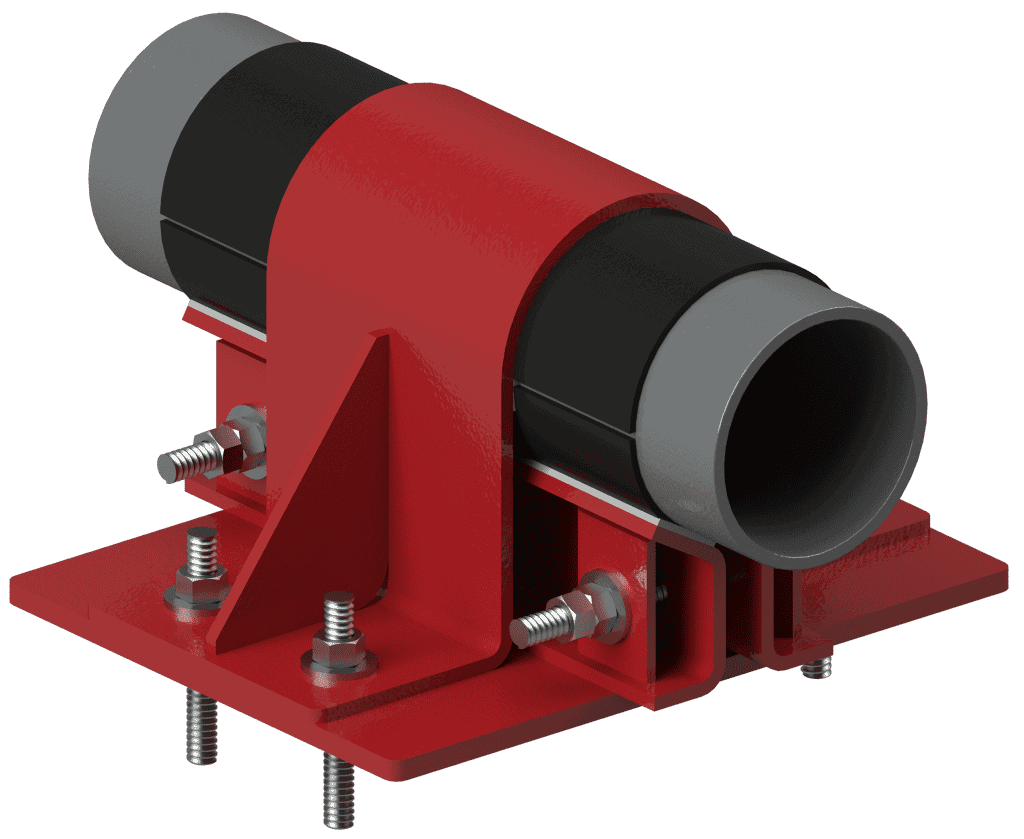

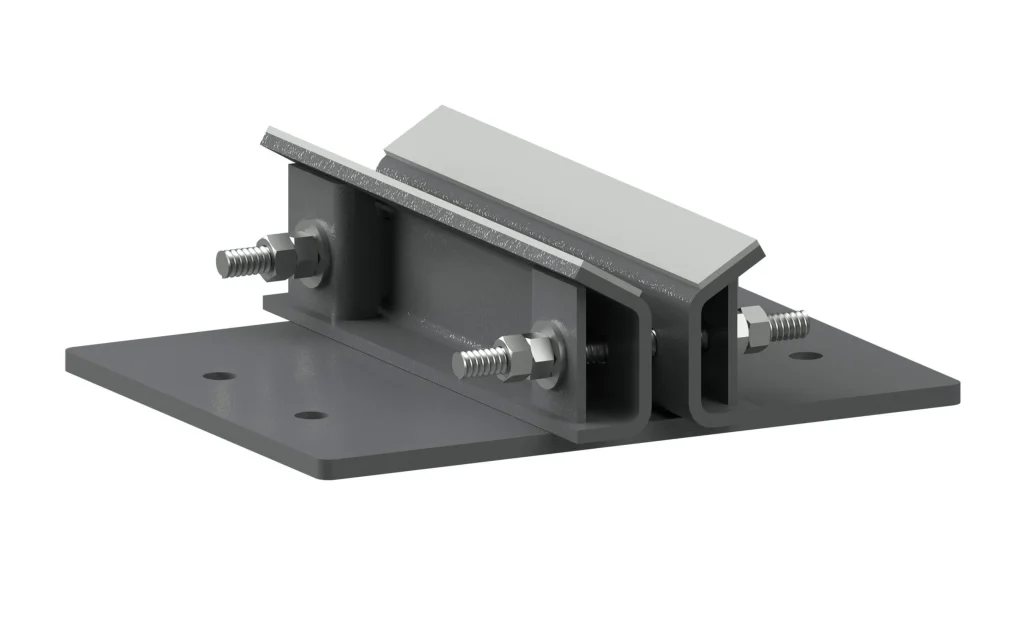

A shim block assembly is an integral component designed for supporting and adjusting the height of piping systems, while allowing pipe axial movement. These assemblies consist of precision-cut metal blocks that align with a threaded rod, allowing for meticulous height adjustments. This feature ensures precise leveling and stable support, allow axial pipe movement to accommodate thermal expansion and contraction, and distribute loads evenly, thus preventing structural strain. The assembly can be used alone or integrated with a hold-down clamp.

RedLineIPS Shim block assemblies are available in a diverse range of configurations and material, including non-metallic types, to suit different applications.

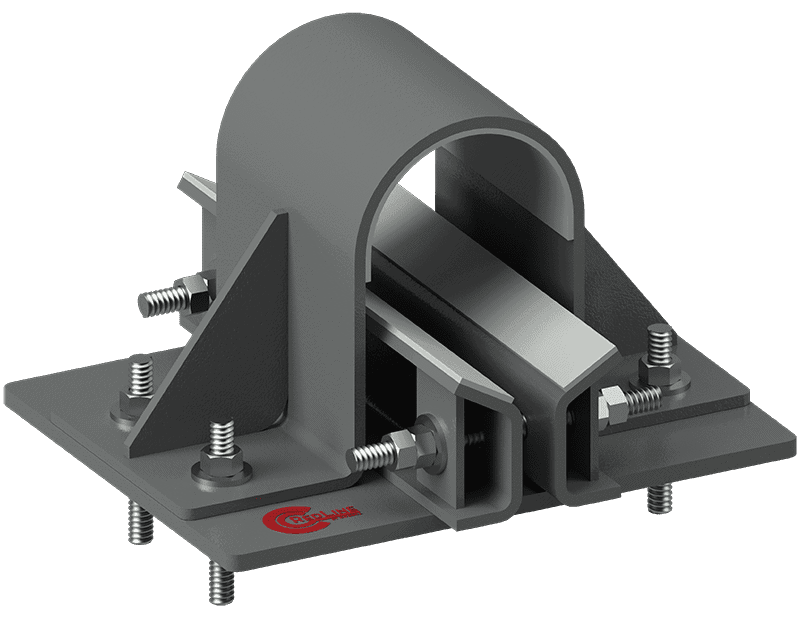

Components of RedLineIPS Shim Block Assembly

RedLineIPS’ line of heavy-duty shim block assemblies typically includes the following components:

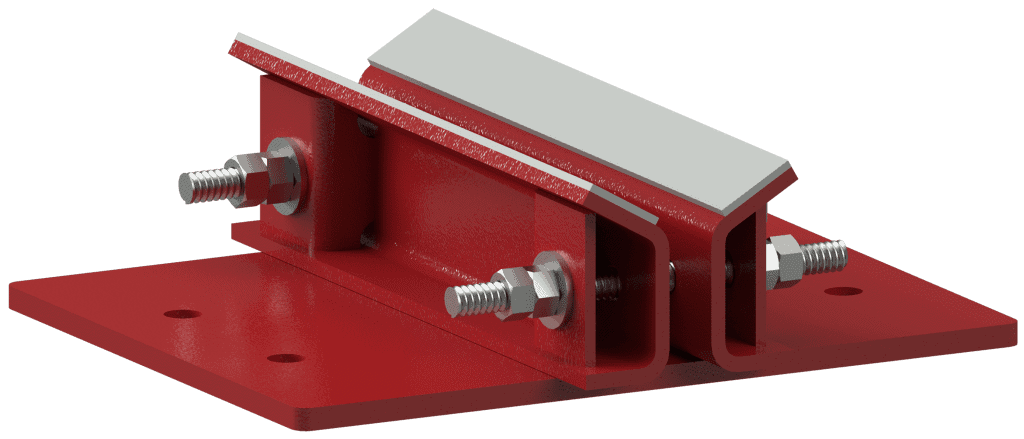

- Adjustable Support Block: This critical component consists of two bent plates supported by stiffener plates. Its unique configuration enables it to provide support to a pipe from underneath. It serves as the primary load-bearing element that holds the weight of the pipe.

- Stiffener Plates: Four sets of stiffener plates complement the adjustable support block. They offer additional structural support and rigidity to the assembly, enhancing its ability to hold and support steel pipes and their contents. The stiffener plates contribute to the overall stability of the assembly.

- Fastener Assemblies: The fastener assemblies, which may include all-thread rods, heavy hex nuts, washers, or other appropriate fastening mechanisms, play the critical role in enabling adjusting the height and position of the shim blocks. By either bringing the shim blocks closer together or moving them apart, these fasteners enable pipe height adjustments, allowing for optimal pipe alignment. This makes the assembly a type of adjustable pipe supports. If you would like more information about our full line of customizable adjustable pipe supports, click here.

This image is interactive. Click on any red marker for more information.

1 of 8Adjustable Support Block

2 of 8Bent Plate Stiffener

3 of 8Anchor Point

4 of 8Bent Plate Stiffener

5 of 8Anti-Corrosion Liner

6 of 8All Thread with Hex Nuts

7 of 8Base Plate

8 of 8- Base Plate: The shim block assembly is typically mounted on a base plate. This base plate is secured to the supporting structure using bolts or other suitable attachment methods. The base plate not only provides stability to the assembly but also contributes to its structural integrity. Additionally, it can be used to secure an optional hold-down clamp, enhancing the overall functionality of the assembly. The base plate may also be mounted on a slide plate to allow further limited movement of the support assembly. For more information about RedLineIPS slide plates click here.

- Optional Liners: In environments where corrosion, vibration, and noise are prevalent concerns, optional liners can be used to protect pipes from friction and vibration, as well as prevent metal-to-metal contact that causes galvanic corrosion. These non-metallic liners can be applied to both the shim block assembly, to the inside perimeter of an optional hold-down clamp, and to the top side of the base plate. Common liner materials include PTFE, FABREEKA and FRP, among others, which effectively reduce wear, mitigate friction, prevent corrosion, dampen vibration, and reduce noise, ensuring the longevity and reliability of the piping system. Please visit our liners page for more information.

Installation and Operation

The installation and operation of a shim block assembly are essential for achieving pipe alignment and support within a piping system. The following is a step-by-step guide on how the process typically works:

1. Initial Positioning

- Begin by placing the base plates in the correct location and orientation to align the holes in the base plates with the corresponding holes in the supporting structure.

- Secure the base plates in place by applying and tightening bolts. These bolts are instrumental in stabilizing the assembly and ensuring its secure attachment to the supporting structure.

2. Shim Block Placement

- Position the shim blocks beneath the pipes at the specific points where height adjustment is required. This step is crucial, as it determines where the pipes will be raised or lowered to achieve the desired alignment and support.

4. Adjustment

- To raise or lower the pipes and attain the desired elevation, adjust the fasteners.

- Tightening the fasteners brings the support blocks closer to each other, therefore causing the pipes to be lifted up to the desired height. It is important to perform this adjustment incrementally to achieve controlled elevation changes.

5. Fine-Tuning

- The adjustability of the shim block assembly allows for fine-tuning of the height or elevation of the pipes. This is achieved by making small, controlled adjustments to the fasteners.

- Fine-tuning ensures that the pipes are well-aligned and adequately supported, contributing to the overall efficiency, stability, alignment, and reliability of the entire piping system.

Benefits of Shim Block Assemblies for Piping Systems

Shim block assemblies offer a range of significant benefits to piping systems, enhancing their efficiency, longevity, and reliability. Here are some of the key advantages they provide:

- Alignment: Alignment of pipes within a piping network is important for ensuring the efficient flow of materials. Shim block assemblies enable adjustments to achieve correct pipe alignment. This reduces stress on the piping system, promoting optimal performance and preventing issues related to misalignment.

- Support: Shim block assemblies play an important role in providing essential support to pipes and associated structures. Operators can easily adjust the elevation and positioning of pipes, ensuring they are adequately supported and securely held in place. This support is of great importance for the structural integrity of the piping system.

- Adjustability: These assemblies are designed with user-friendly adjustability in mind. They allow for quick modifications to the elevation and alignment of pipes. This flexibility promotes efficient operations and simplifies maintenance tasks, reducing downtime and operational disruptions.

- Corrosion Protection, and Vibration and Noise Mitigation: When corrosion, vibration and noise are constant concerns, shim block assemblies can include specially-designed liners. These liners prevent metal-to-metal contact, reducing wear and tear. Liner materials like PTFE, PVC, and FABREEKA act as a protective barrier, mitigating friction, dampening vibration, and reducing noise. These liners can be attached to either the shim block assembly block, the optional hold down clamp, base plate, or to all components. The use of such liners ensures the longevity and reliability of the piping system, even in harsh conditions and environments, such as offshore platforms and coastal plants and refineries. Visit our liners page for more information and to help you select the right material for your application, or contact us for more information.

FAQ's

Typical Queries and Information

What is a shim block assembly?

A shim block assembly is a height-adjustable pack of plates tied together with threaded rods. By tightening the rods, the plates pull together and raise the support height; loosening them lets the plates separate and the pipe sit lower. Used by itself or built into a hold-down clamp, a shim block assembly lets you fine-tune bottom-of-pipe elevation in the field and re-level supports after minor settlement—without cutting steel or rebuilding the support.

When should I use a shim block assembly instead of a simple fixed support?

Shim block assemblies are used where you need precise elevation control or the ability to re-set height later. Typical cases include correcting misalignment from uneven steel or grade, dialing in exact top-of-steel to bottom-of-pipe dimensions after stress runs, or giving yourself a way to compensate for future settlement without redesigning and refabricating the support.

How does a shim block assembly work with hold-down clamps?

In a combined arrangement, the shim block assembly sets the height and carries the vertical load, while the hold-down clamp bolts over the pipe to provide restraint. The shim block handles alignment and elevation; the clamp keeps the line seated and controlled during thermal movement and vibration. This separation of roles makes it easier to re-level the support later by adjusting the shim block while leaving the clamp hardware in place.

Do shim block assemblies allow the pipe to move with temperature changes?

Yes. Shim block assemblies are typically detailed so the pipe can move axially to accommodate thermal expansion and contraction while the block carries the vertical load. Depending on the design, the pipe may slide on a liner inside a clamp or on a slide plate under the shoe or base, allowing movement along the line without over-stressing the pipe or the support steel.

Can shim block assemblies include liners, and how do they help with CUPS and vibration?

Shim block assemblies can incorporate non-metallic liners and slide surfaces such as PTFE, PVC, FABREEKA-type pads, FRP, and other engineered materials. These liners reduce friction, damp vibration and noise, and provide a dielectric barrier between the pipe and steel. By elevating the pipe and breaking direct metal-to-metal contact, a lined shim block assembly also helps reduce moisture traps and galvanic couples at the support point, supporting your efforts to control corrosion under pipe supports (CUPS).