Introduction

The RedLineIPS SmartPad System, developed by Cogbill and currently pending patent approval, offers a groundbreaking solution to combat the pervasive issue of corrosion in industrial piping systems, specifically at pipe support points, commonly referred to as “Corrosion Under Pipe Supports” (CUPS) or “Corrosion Under Supports” (CUS). This problem arises from the dynamic interaction between pipes and their supporting structures, leading to a chain of events that culminate in pipe corrosion and potential failure.

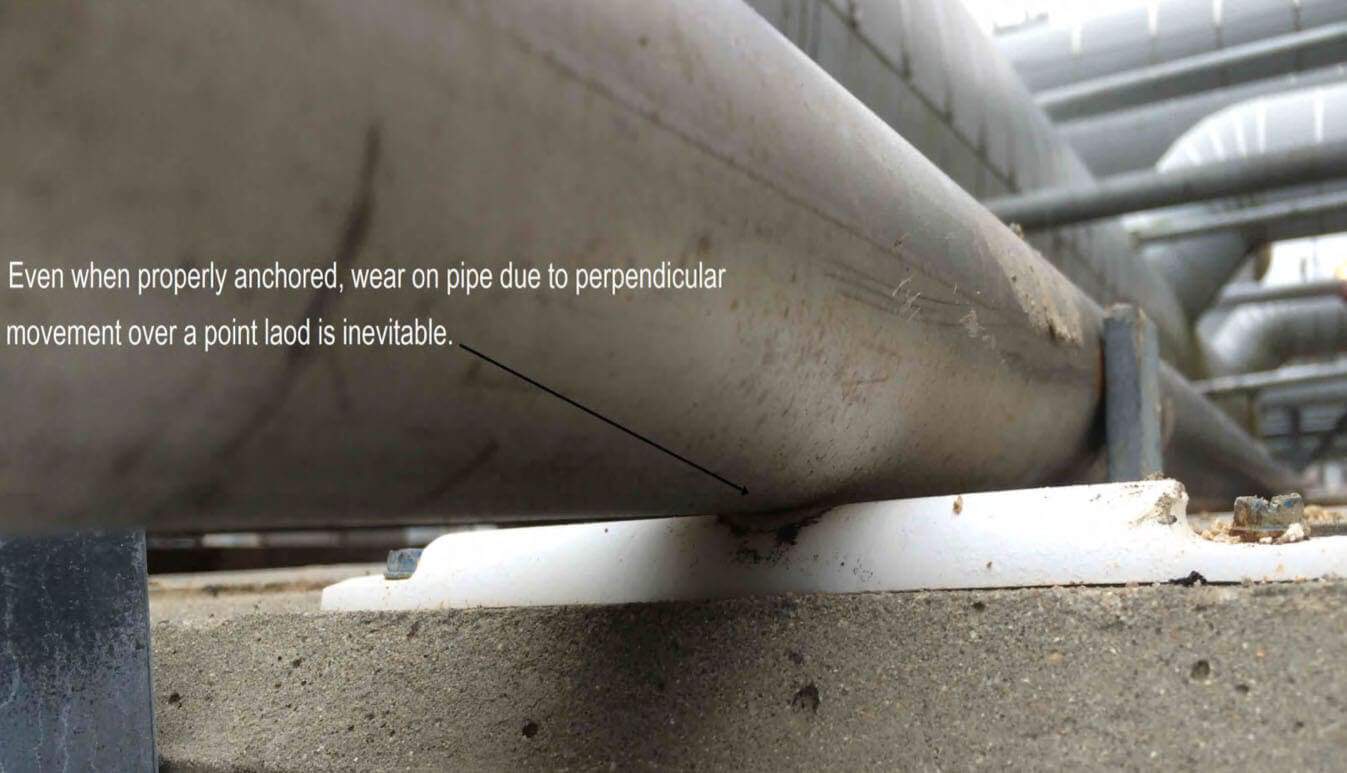

When pipes rest on their supporting structures, the natural movement and vibration of the pipes, caused by factors such as rotating machinery, fluid flow, and temperature fluctuations, lead to friction between them and their supports. Over time, this friction erodes the protective paint coating on the pipes, exposing them to the elements. Furthermore, restricted airflow in these areas retains water molecules, creating an environment conducive to corrosion, specifically crevice corrosion. Additionally, the mere metal-to-metal contact between pipe and support promotes galvanic corrosion. This sequence of events ultimately results in pipe corrosion and failure.

The SmartPad system introduces a multifaceted approach to tackling and preventing the CUPS issue, focusing on four crucial elements:

- Saddle Design for Protection: The SmartPad's distinctive shape cradles the pipe, effectively shielding its protective coating from erosion resulting from friction between the pipe and its supporting structure.

- Moisture Prevention: The SmartPads are meticulously engineered to prevent the formation of water molecules between the pipe and the pad, with its Hydroseal NEMA-4-rated water seal gasket. This eradicates the conditions conducive to crevice corrosion, a common problem in such scenarios.

- Metal-to-Metal Prevention: All components of the SmartPad system are crafted from resilient, non-metallic materials that effectively separate a metallic pipe from its metallic supports. This preventive measure thwarts the occurrence of galvanic corrosion, further fortifying both the piping system and its supports, ensuring the overall integrity of the entire system.

- Quick Installation & Removal: The system's innovative design and versatile components enable the swift installation, removal for inspection, and reinstallation of the pads in just a matter of minutes. This facilitates cost-effective visual corrosion inspections, eliminating the need for pricier alternatives like ultrasound and radiography required by competing solutions. As a result, maintenance costs are significantly reduced.

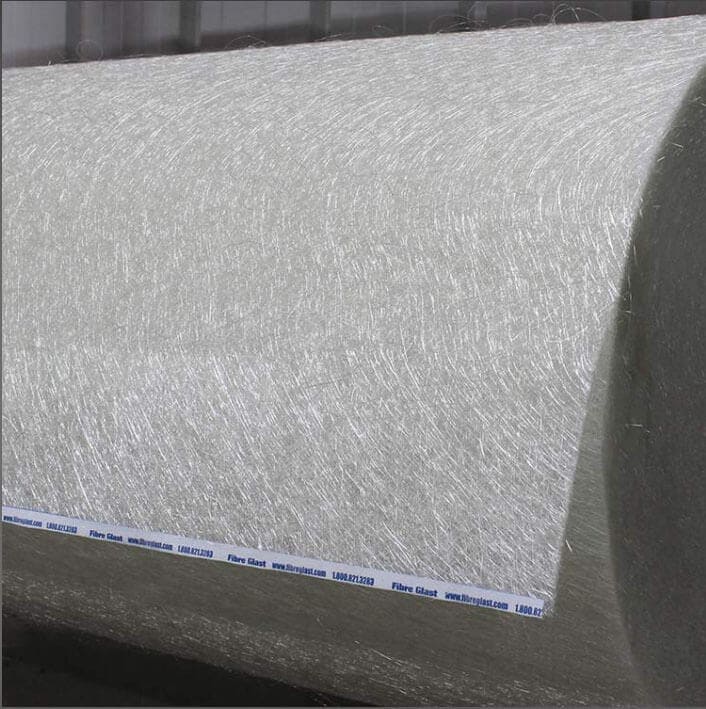

Constructed entirely from fiber-reinforced plastic, an epoxy-free composite material, the system incorporates specialized Hydroseal gaskets, patented composite straps, and innovative tooling systems to securely attach SmartPads to industrial piping within seconds. The SmartPad’s design ensures it supports the pipe without causing point-loading, concurrently providing corrosion protection at critical support points. This negates the need for adhesives, such as epoxy, which simplifies installation and eliminates associated challenges and costs associated with bonding wear pads to pipes. Moreover, the absence of metallic components in the system guarantees immunity to corrosion, as well as obviating the necessity for welding and welding permits or line shutdowns during implementation.

The RedLineIPS FRP SmartPad System presents a solution to a costly problem that afflicts industries worldwide. Substantial resources are annually allocated to repairing and recoating pipe surfaces damaged by friction and metal-to-metal contact that leads to corrosion. These expenditures are compounded by the enormous economic losses attributed to corroded piping. Corrosion at pipe support points not only affects financial budgets but can also trigger expensive shutdowns and potentially catastrophic failures.

Cogbill’s innovation seamlessly integrates established materials and components with cutting-edge technologies, culminating in a solution that delivers faster, safer, more intelligent, and cost-efficient pipe supports. The RedLineIPS SmartPad System holds the potential to revolutionize the industry by providing a comprehensive response to the challenges posed by CUPS, ultimately offering heightened value and performance.

Cogbill Construction, LLC

Cogbill Construction was established in 1999 to serve industrial customers in Southeast Texas and Southwestern Louisiana, in the areas of metal fabrication, industrial construction, and plant shutdowns and turnarounds. Two decades later, Cogbill has added custom composite (FRP) fabrication services, and now serves the entire North American continent and the world at large with its products and services.

Our composite (Fiber Reinforced Plastics, FRP) fabrication services and products focus on pipe corrosion and vibration protection. Such products include the RedLineIPS SmartPads System (the epoxyless version of FRP wear pads), epoxied-on FRP Wear Pads, FRP Slide Plates, FRP Clamp SmartInserts, FRP flanges, and FRP ducts and panels, to name a few.

Corrosion Under Pipe Supports (CUPS)

A direct outcome of this continuous movement is the interaction between the pipes and their support structures. This ongoing contact can lead to friction and abrasion, ultimately causing a gradual erosion of the protective coating on the pipes. As this protective coating becomes compromised, the pipes become exposed to environmental elements, including humidity, heat, salt, and oxygen. These environmental factors can accelerate corrosion processes within the piping system.

Existing Solutions

- Metallic Wear Plates

These steel plates, which cradle pipes, are either fully welded or tack-welded to the pipe at the contact regions to protect against friction. While they can be effective in protecting the paint coating, they have limitations. They don’t prevent corrosion from occurring, since metal-to-metal contact still exist, and their installation process typically necessitates line shutdown, welding permits, and skilled operators. This can result in production halts and expensive maintenance costs. Additionally, moisture trapped in crevices between the pad and pipe can create hidden corrosion cells that are hard to detect.

- Metallic and Plastic Round Bars

- Rubber, Neoprene, TEFLON, and PTFE Sheets

- Traditional FRP Wear Pads

- Installation Duration: The installation process is time-consuming, typically taking 30 to 60 minutes. The time required can vary based on the installer's experience and various environmental factors.

- Surface Preparation: Thorough cleaning and roughening of the pipe's surface are necessary for proper epoxy adhesion.

- Cure Time: After installation, an additional 24-hour cure time is essential for the epoxy to effectively bond the pad to the pipe.

- Epoxy Application: The epoxy must fully cover the inner surface of the pad, and a perimeter bead of epoxy around the entire pad is necessary to prevent water molecules from entering the pad/pipe interface.

- Risk of Water Ingress: Dirt, impurities, or imperfect workmanship can allow water molecules to penetrate between the pad and the pipe, rendering the pads ineffective in protecting pipes from corrosion.

- Weather Sensitivity: The use of epoxy can be particularly challenging and messy during hot summer conditions, and nearly impossible in extremely cold weather.

- Installer Experience: Installer experience plays a crucial role in ensuring a successful installation.

- Inventory Management: The process requires the maintenance of several components on hand.

- Paint Touchup: The process may entail the need for paint touch-up after installation.

The SmartPad System

The SmartPad System represents an innovative solution, leveraging components and materials that have been available on the market for many years. However, these components have been either redesigned or ingeniously combined to address the CUPS problem more effectively and at a fraction of the cost compared to competing solutions.

In summary, the SmartPad System safeguards piping systems from external corrosion at the pipe support points through the following steps:

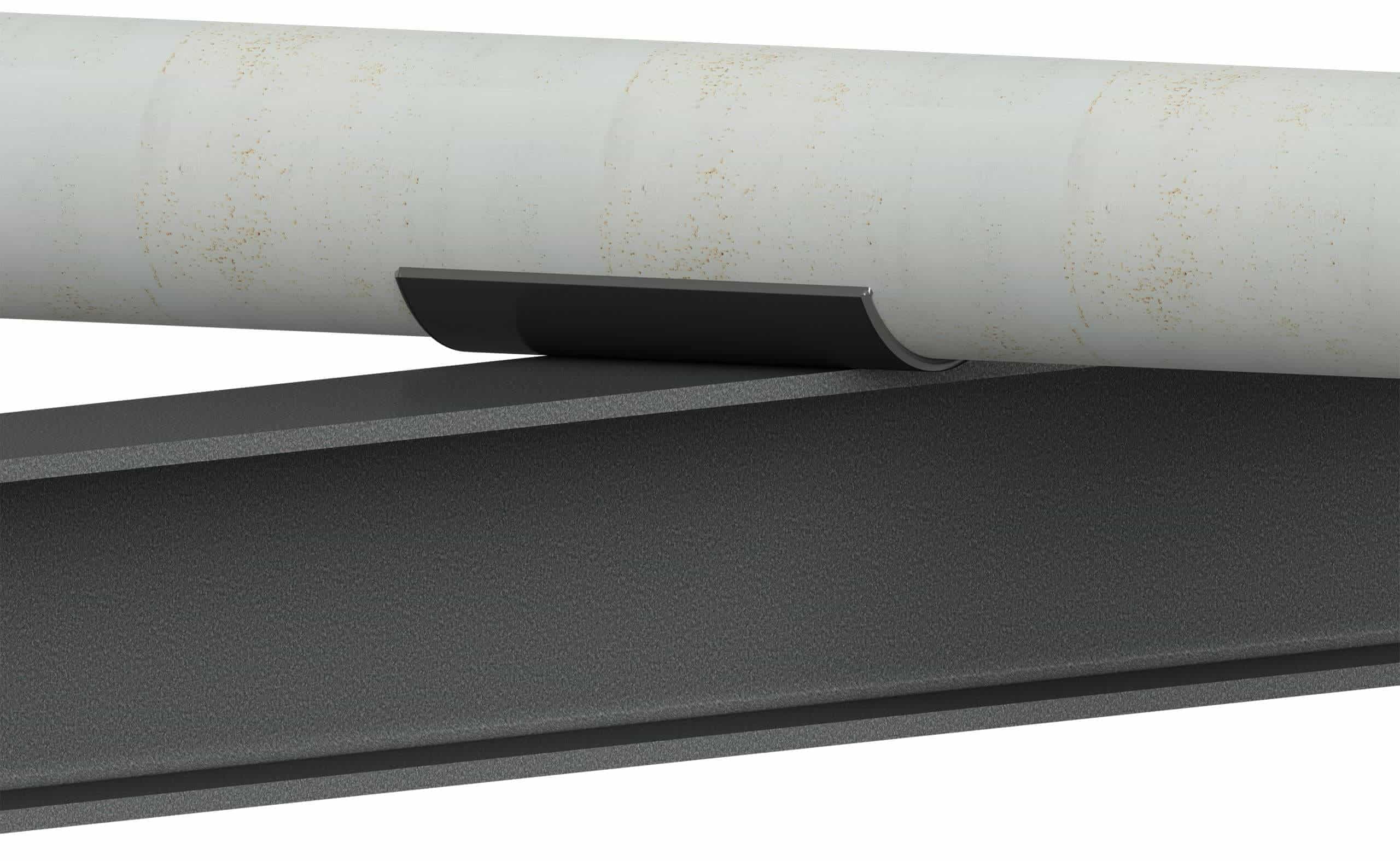

- SmartPads: These are all-composite FRP wear pads, distinguished by innovative design enhancements. Notably, they feature recessed grooves that serve the dual purpose of securely anchoring our SmartBands and providing protection against potential damage from contact with the pipe support. Additionally, these non-conductive FRP pads play a crucial role in preventing galvanic corrosion by eliminating metal-to-metal contact.

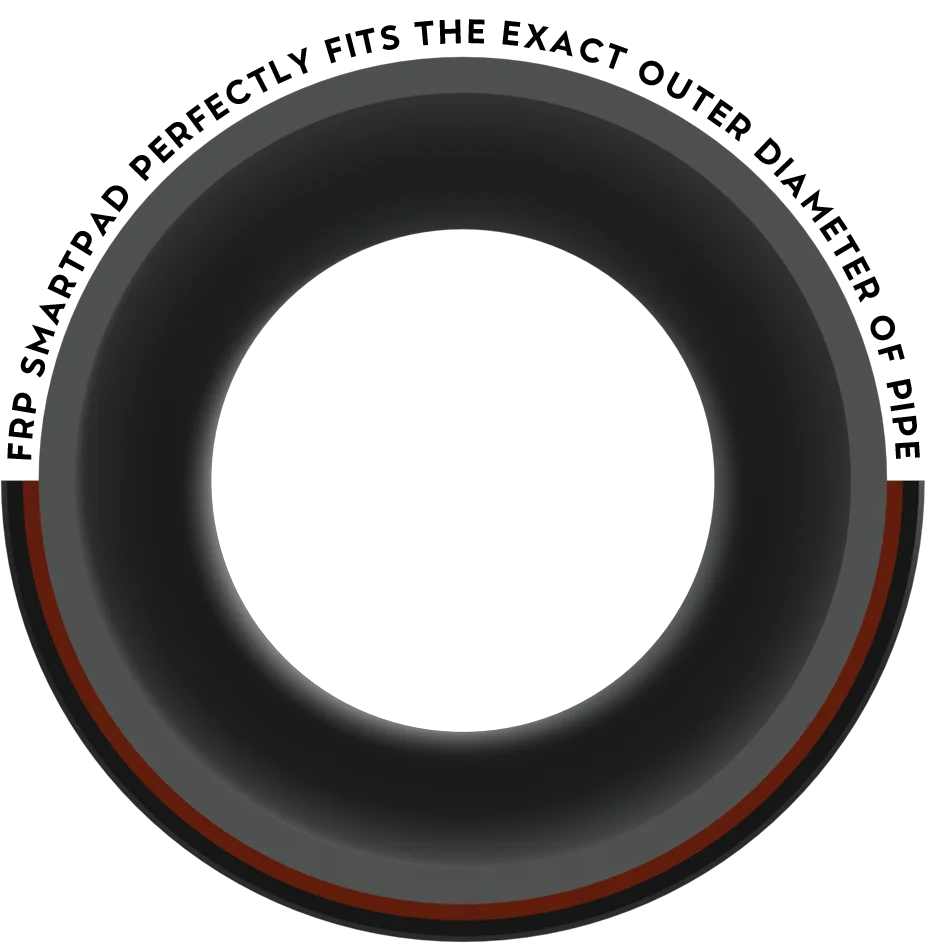

- Hydroseal Gaskets: Each SmartPad comes pre-installed with a closed-cell Hydroseal gasket on its inner surface, capable of providing a NEMA-4 watertight seal when compressed.

- Isolation and Protection: The SmartPad, along with its Hydroseal gasket, is positioned underneath the pipe at the support point. This isolates the pipe from its supporting structure and shields it from wear.

- SmartBands: Composite SmartBands are looped around each SmartPad into the recessed grooves, and composite buckles are affixed to these bands.

- SmartTool Application: The SmartTool is employed to efficiently apply a high rate of tension to tighten the SmartBands, thus compressing the Hydroseal gasket. Combined with the pipe's compressive load, this creates a NEMA-4 watertight seal, effectively preventing moisture ingress between the pad and the pipe.

- Excess Banding Removal: The SmartTool's built-in clipping mechanism is used to remove any excess banding.

- Rapid Installation: The installation process takes mere seconds to complete.

- Quick Inspection and Reinstallation: The SmartPads can be swiftly removed by cutting off the SmartBands, enabling a visual inspection of the pipe for external corrosion. Subsequently, they can be reinstalled, once again in seconds, using the original SmartPad and gasket.

- Friction Protection: The SmartPad's body acts as a shield, safeguarding the pipe's surface from friction at the contact region, thereby preserving the pipe's protective coating.

- Elevation Effect: The installation of these pads elevates the pipes above their supporting structure, effectively enhancing airflow and minimizing the potential for crevice corrosion.

SmartPad System Components

- Composite (FRP) SmartPad

- Hydroseal Gasket

- SmartBand & Buckle (all composite)

- SmartTool

- Chemical Resistant Option: PTFE Strips

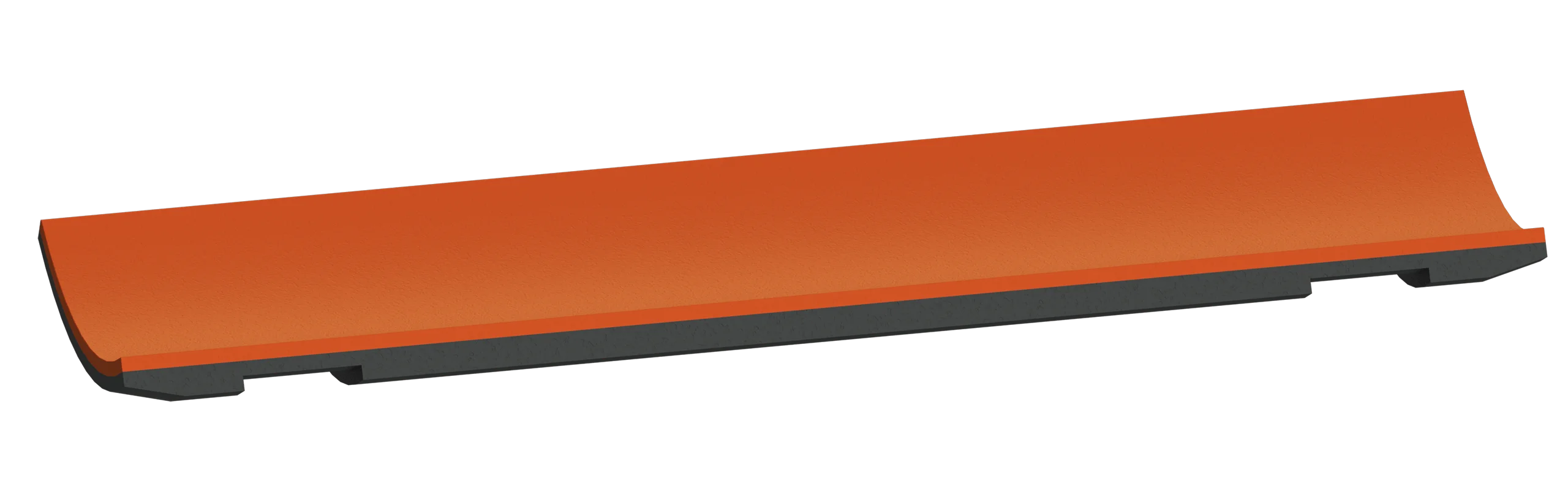

- Composite (FRP) SmartPad

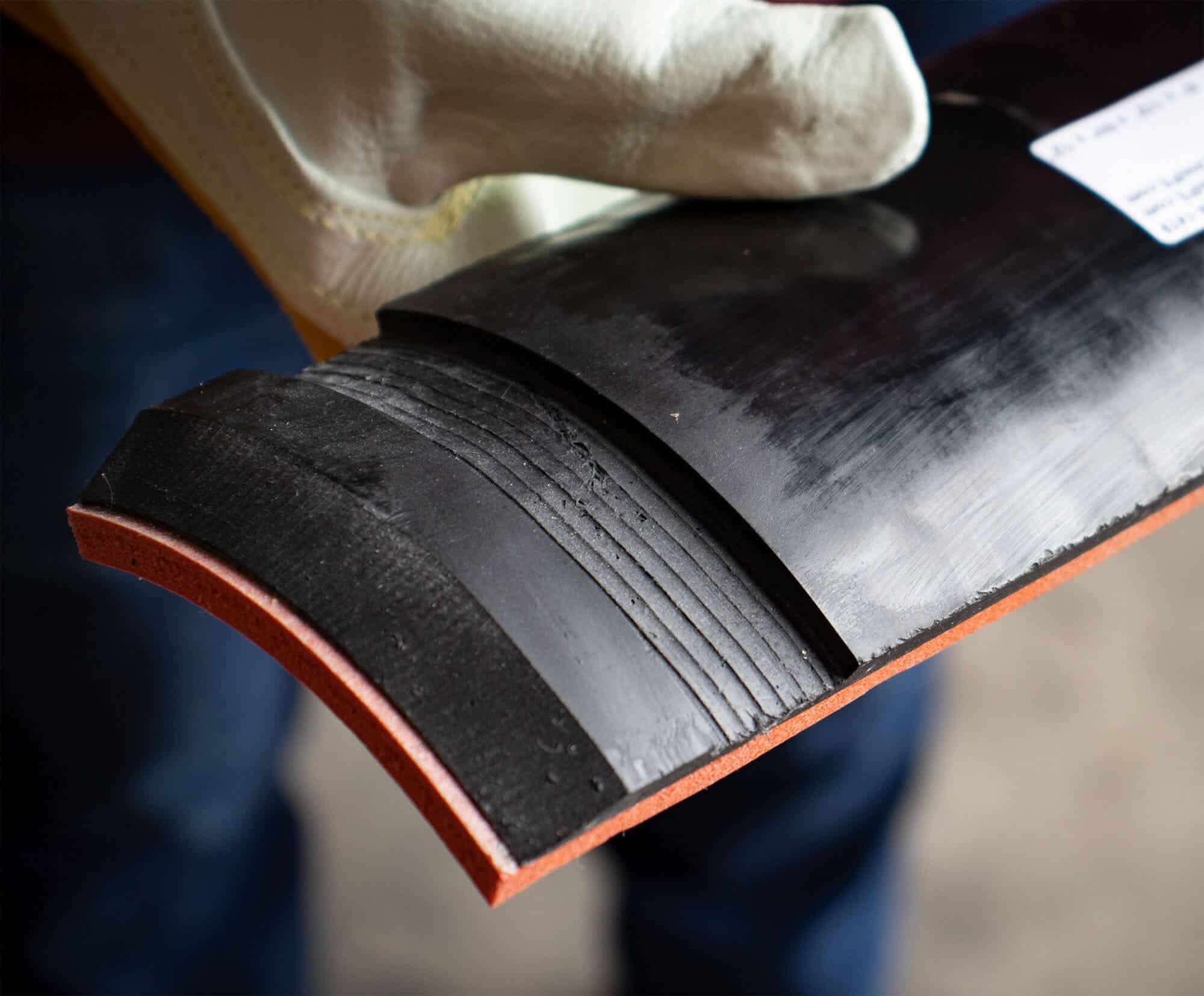

The SmartPad is meticulously engineered for optimal performance as a pipe support. It features an exoskeleton composed of a composite material, created by laminating and impregnating numerous layers of continuous strand mat with high-quality vinyl ester resin. This robust design distinguishes it from typical FRP wear pads produced by other manufacturers, who often repurpose low-cost filament-wound FRP duct or pipe/tubing originally intended for carrying corrosive internal media, not for pipe support purposes.

Each SmartPad incorporates two recessed grooves designed to securely accommodate SmartBands during installation. This innovative feature not only protects the SmartBands but also prevents their unintended slippage when the pads move in tandem with pipe motions over support structures.

Our specialized manufacturing process ensures that each SmartPad is custom-made to precisely match the outer diameter of the pipe it protects, guaranteeing an impeccable seal between the pad and the pipe.

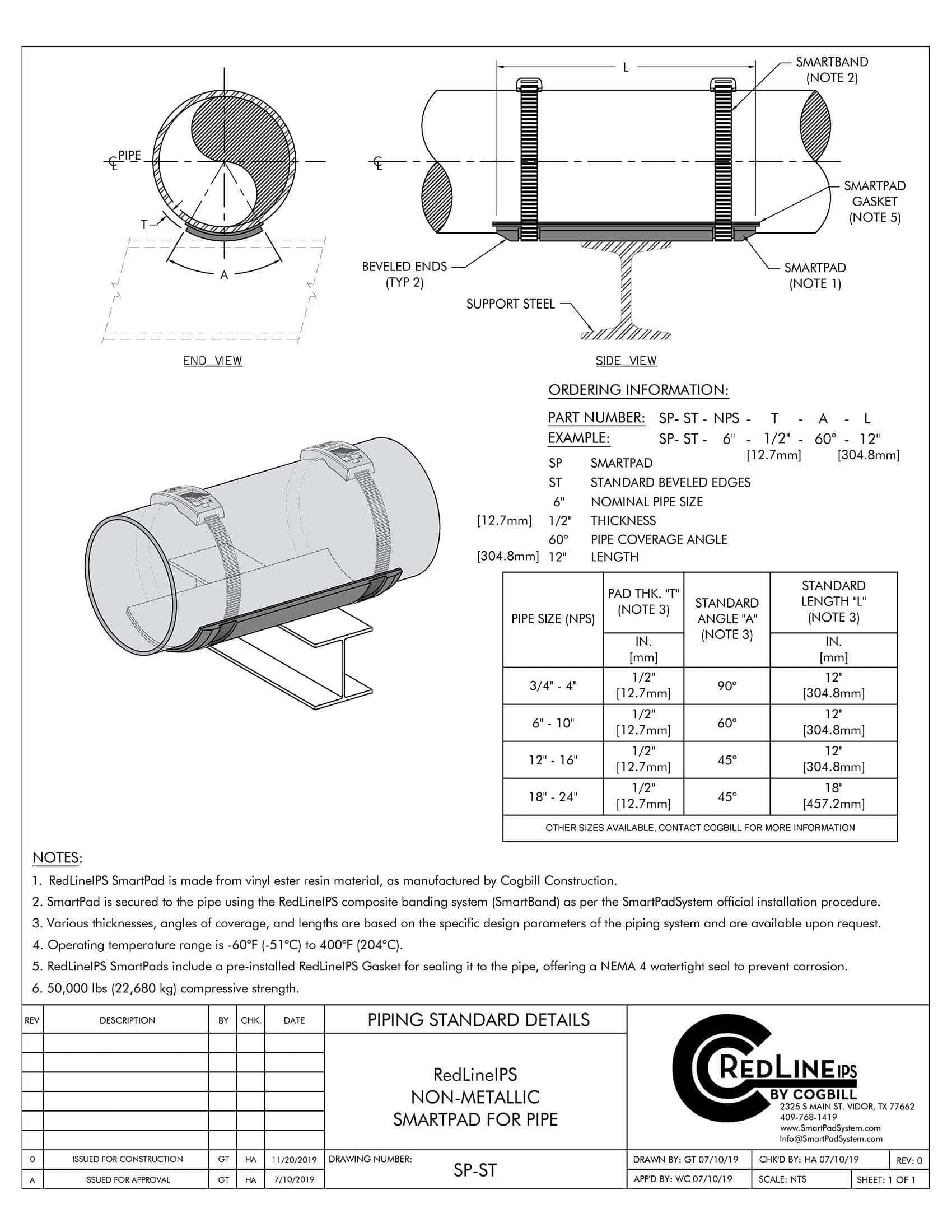

SmartPad Features

- Crafted from continuous strand mat laminated vinyl ester resin.

- Purpose-built, manufactured, and tested for pipe support applications.

- UV resistant and load tested for peak performance in demanding environments.

- Recessed grooves prevent SmartBands from slipping.

- Sloped edges aid in the repositioning of the pad and pipe.

- Effective vibration dampening and enhanced impact resistance.

- Customizable in terms of length, thickness, and angle of coverage.

- Suitable for temperatures ranging from -60°F to 400°F (-51°C to 204°C).

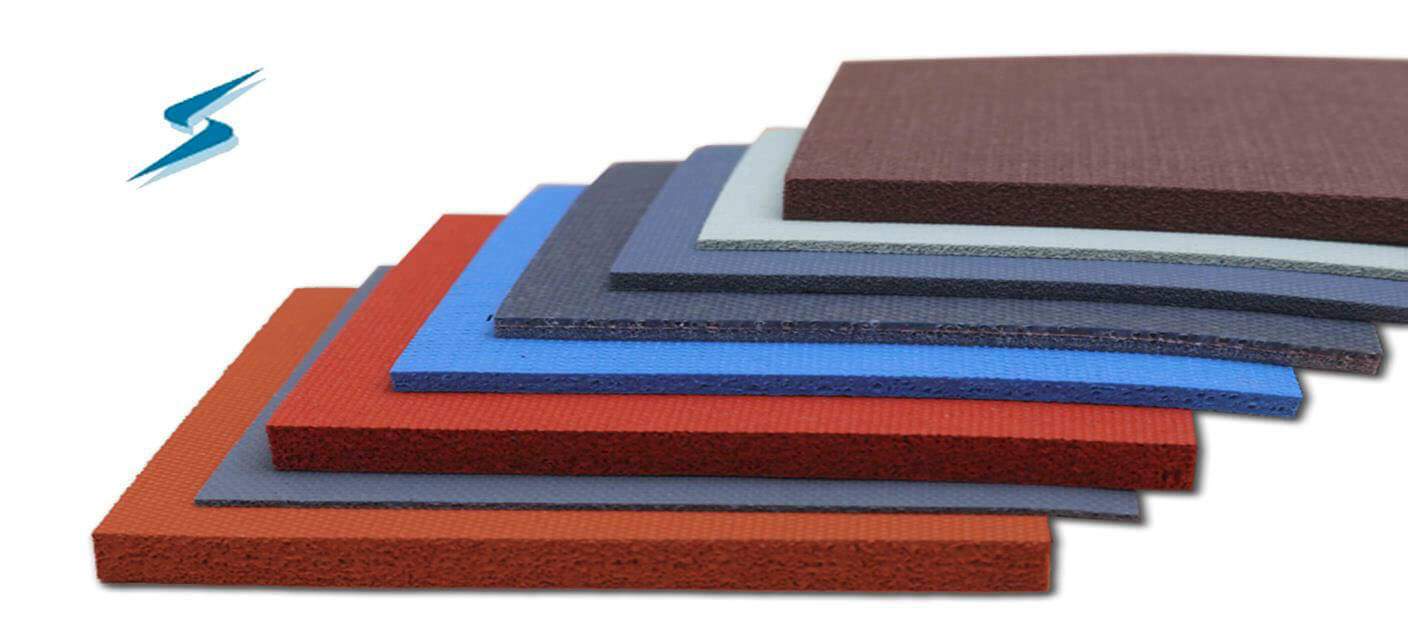

- Hydroseal Gasket

The Hydroseal gasket within our SmartPad system plays a pivotal role in preventing the intrusion of water molecules into the interface between the pad and the pipe, thereby averting corrosion. This critical component is characterized by its closed-cell structure, reminiscent of a memory-foam mattress tailored for pipes. When compressed, the gasket dynamically conforms to the outer surface of the pipe, effectively dampening vibrations and enhancing impact resistance.

However, the standout feature of our Hydroseal gasket lies in its ability to establish a watertight NEMA-4 seal when compressed between the pipe and the SmartPad’s exoskeleton. This accomplishment effectively addresses a longstanding challenge associated with FRP wear pads and analogous solutions that rely on epoxy to achieve a watertight seal.

Our gasket system eradicates the possibility of moisture becoming trapped between the pad and the pipe, thus eliminating the conditions conducive to corrosion cell formation. In contrast, installer errors in epoxy-based systems can inadvertently lead to moisture entrapment and the subsequent development of severe crevice corrosion problems, often concealed and undetected for extended periods—issues our patented system rectifies.

Hydroseal Gasket Features

- Resilient closed-cell elastomer that adapts to a pipe's outer surface to establish a waterproof NEMA-4 seal upon compression.

- Eliminates the need for a perimeter epoxy seal.

- Precludes the occurrence of moisture traps.

- Guards against faulty installations.

- Broad temperature tolerance spanning from -60°F to 570°F (-51°C to 300°C).

- Constructed from long-lasting materials such as Silicone, PTFE, EPDM, and more.

- Offers chemical-resistant variants for challenging environments.

- Well-suited for harsh settings including coastal and offshore locations.

- SmartBand & Buckle

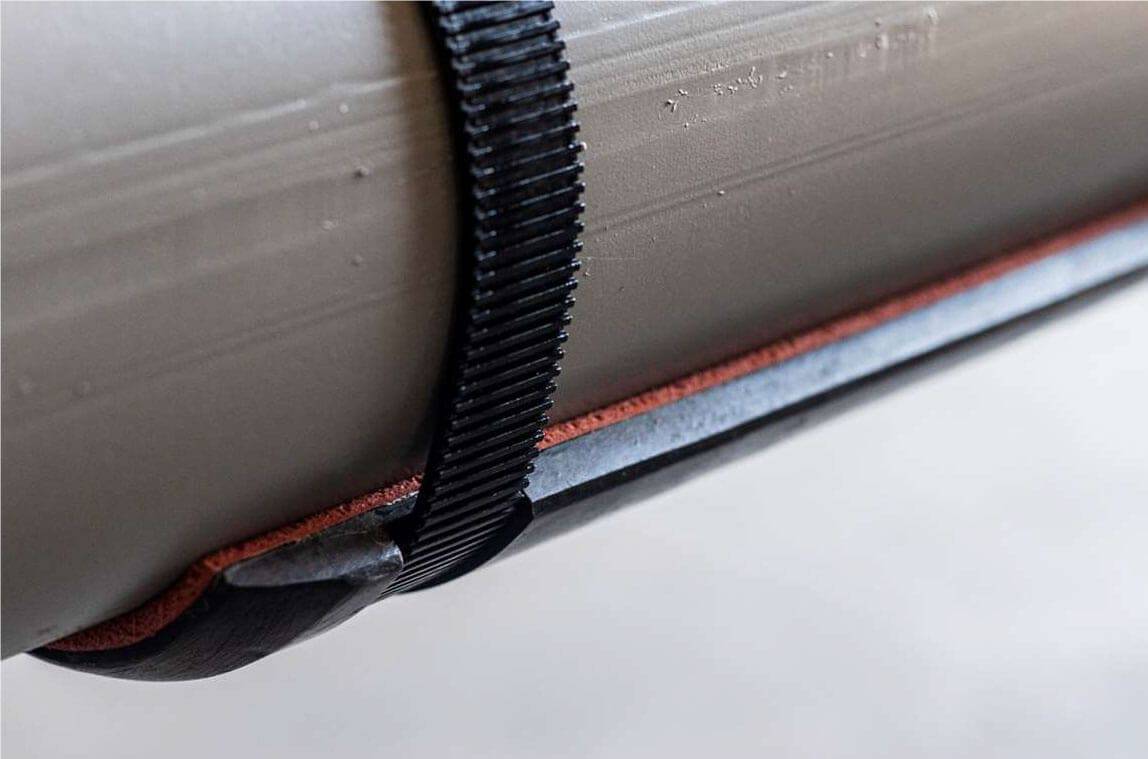

Our SmartPad System employs SmartBands to secure the SmartPads onto pipes. These SmartBands are robust, continuous-strand fiber-reinforced polymer straps devoid of any metallic components. When tensioned using the SmartTool, they fasten securely, eliminating the risk of slipping or detachment. The sole method for their removal is cutting.

The significant tension applied, combined with the pipe’s weight, results in the compression of the Hydroseal gasket. This compression is the linchpin behind the creation of the NEMA-4 watertight seal, a formidable defense against water molecule accumulation between the pads and the pipe. This accumulation is a known catalyst for corrosion (CUPS) over time.

Each SmartBand is equipped with teeth that forestall tension release over time. Consequently, the NEMA-4 seal remains intact throughout the SmartPad’s lifespan, which is estimated to range between 20 and 30 years, with the potential for even longer service.

SmartBand Features

- Heavy-duty continuous-strand fiber-reinforced polymer straps and buckles.

- Composed entirely of non-metallic, non-corrosive materials.

- Smooth inner surface, ensuring safety for a pipe's coated surface.

- Features low-profile buckles.

- Demonstrates high strength, capable of withstanding forces up to 5,793 lbf.

- Built to last with long-life materials.

- Safe and easy to fit, facilitating straightforward installation.

- Supports high-speed installation processes.

- Maintains a high retention force.

- Suitable for subsea applications, expanding its versatility.

- SmartTool

The RedLineIPS SmartTools are purpose-built for the precise tensioning of SmartBands, securing the SmartPads to the pipe with the requisite force to endure throughout the system’s operational lifetime. Regardless of the variant, these tools possess the capability to exert ample force to compress the Hydroseal gasket, establishing a steadfast NEMA-4 watertight seal. Importantly, this occurs without factoring in the weight of the pipe itself, effectively preempting corrosion formation between the pad/gasket and the pipe.

The SmartTools are available in three varieties:

- Manual: For expedited operation

- Mechanical: Offering precise application of specific force ratings per engineering standards

- Pneumatic: Enabling swift installation of significant quantities of SmartPads

SmartTool Features

- Swift and straightforward operation.

- Ergonomically designed for user comfort.

- Manual, mechanical, or pneumatic options.

- Capable of applying high force rates.

- Establishes a NEMA-4 watertight seal between pad/gasket and pipe.

- Includes a built-in clipping mechanism for excess banding material.

- Suited for subaqueous applications, expanding its utility.

- Optional: PTFE Strips, Chemical Resistant Option

Certain chemical processes involve exceptionally corrosive substances that could potentially harm the SmartPad or the Hydroseal gasket. To safeguard against such corrosive chemicals, a PTFE (Polytetrafluoroethylene) strip can be applied around the periphery of the Hydroseal gasket. This protective measure extends to shielding the edges of the SmartPad from these harmful materials. While PTFE is the most prevalent choice, various other materials can also serve this purpose, depending on the chemical application at hand. In the photo model, these strips are represented by the white material at the perimeter.

SmartPad System Installation Process

Installation Steps

- Raise the Pipe: Follow your facility's standard operating procedure (SOP) to raise the pipe.

- Corrosion Inspection: If corrosion is present, address it according to your facility's SOPs.

- Clean the Pipe: Use a wet towel to thoroughly clean the pipe, removing dirt and debris.

- Dry the Pipe: Dry the pipe well using a dry towel or allow it to air-dry.

- Position the SmartPad: Place the SmartPad in the desired location underneath the pipe, above the support.

- Secure with SmartBands: Loop the SmartBands around the pipe and through the banding recesses. Pull the bands through the buckle.

- Tension the Bands: Utilize the SmartTool to tension the bands securely.

- Trim Excess Material: Cut off any excess band material.

- Lower the Pipe: Lower the pipe according to your facility's SOPs.

- No Additional Processes: No epoxy, welding, or line shutdowns are required.

- Removal: To remove the SmartPad, cut off each SmartBand as per your facility's SOPs, using sharp tools, and then remove the SmartPad.

- Reinstallation: For reinstallation, follow the same process as above, using the existing SmartPad and Hydroseal gasket, along with the same buckles, but replace the SmartBands with new ones.

Speed of Installation

The RedLineIPS SmartPad System outperforms all competitors in terms of ease and speed of installation. SmartPads can be installed in mere seconds, whereas alternative solutions often involve time-consuming processes such as welding, applying epoxy or adhesives, bolting and torqueing, etc. For instance, the installation of epoxied-on FRP wear pads can take experienced installers between 30 to 45 minutes, along with an additional 24 hours or more for epoxy curing, depending on environmental conditions like temperature and humidity. The level of installer experience significantly impacts the successful installation of these pads. Importantly, the SmartPad System does not necessitate any curing time.

Moreover, our system eliminates the need for installers to perform touch-up work to seal the pad to the pipe, as no epoxy is used. Additionally, our self-sealing Hydroseal gasket is designed to minimize the risk of faulty installations, enhancing overall safety and efficiency.

In the rare event that a SmartPad is incorrectly installed or placed in the wrong location, it can be effortlessly removed and reinstalled with minimal time and cost. The same applies when a SmartPad needs to be removed for visual inspection; this process takes only seconds. In contrast, epoxied-on FRP wear pads cannot be removed once the epoxy cures, even for inspection purposes, unless chiseled off. Welded metallic wear pads pose an even greater challenge for removal.

For a side-by-side installation comparison between our SmartPads System and epoxied-on FRP wear pads, please refer to this video comparison. The test demonstrated that it took less than two minutes to install a SmartPad versus twelve (12) minutes for an epoxied-on wear pad, conducted on a brand new pipe by an experienced and proficient installer. On average, contractors typically charge clients 1-1.5 hours per FRP wear pad for installation when considering surface preparation and paint touch-up work afterwards.

SmartPad System Benefits

The SmartPad System is a cutting-edge solution designed to combat the costly issue of corrosion under pipe support (CUPS). While various competing solutions exist, the SmartPad System distinguishes itself by offering a multitude of unique advantages and benefits that no other solution can match. Some of these exceptional benefits include:

- Heavy-Duty, All-Composite Material: SmartPads are constructed from robust composite materials, ensuring long-lasting durability.

- Eliminates Metal-to-Metal Contact: The system eradicates the risk of metal-to-metal contact, thereby preventing galvanic corrosion.

- Prevents External Corrosion: Effectively shields piping systems from external corrosion at pipe support points.

- Epoxyless: Offer speedy installation, independent of season.

- Quick Removal and Reinstallation: Enables swift removal and reinstallation, facilitating easy visual inspections for corrosion.

- 100% Install Success Rate: Ensures a high success rate for installations, minimizing errors.

- NEMA-4 Watertight Seal: Creates a watertight seal between the pipe and pad/gasket.

- Cost-Effective Visual Inspections: Allows for speedy and cost-effective visual inspections for corrosion, significantly reducing the cost of such inspections.

- Reusable: A cost-effective and environmentally friendly solution, as components can be reused.

- Versatile: Offers a wide range of gasket materials to meet specific applications, including options resistant to corrosive chemicals.

- Dampens Vibration and Noise: Helps dampen vibrations and reduce noise levels in the system.

- Installs on Live Lines: Can be installed on live lines, avoiding costly shutdowns.

- No Welding Permits or Line Shutdown Required: Eliminates the need for welding permits and costly line shutdowns.

- Wide Operating Temperature Range: Suitable for a broad temperature range, from -60°F to 400°F (-51°C to 204°C).

The SmartPad System, with its comprehensive set of advantages, offers a reliable and cost-efficient solution for protecting piping systems against corrosion, making it a versatile choice for a wide range of applications.

SmartPads in Operation

The RedLineIPS SmartPad System has been in service since 2018, primarily in facilities located in or near the Gulf of Mexico region. Presently, several key customers are implementing the system in both pilot programs for full-scale adoption. These customers include prominent companies like Chevron, Formosa, and Nutrien, for facilities situated in close proximity to the Gulf of Mexico or on offshore platforms. These pilot program represents a significant step towards broader industry recognition and adoption of the SmartPad System.

Photo Gallery

Engineering Specifications

For Further Information

Cogbill Construction, LLC

2325 S. Main St. Vidor, TX 77662 U.S.A.

Email:

Phone: +1 (409) 768-1419

Fax: +1 (409) 768-1782

Online Videos

9-Minute Intro Video: Understanding the RedLineIPS SmartPad System

3-Minute Intro Video: The RedLineIPS SmartPad System

1-Minute Intro Video: SmartPads System vs. FRP Wear Pad Installation Comparison

2-Minutes Installation: SmartPad 2 Minute Illustrated Installation Video

1-Minute Installation: SmartPads System 2 Minutes Installation Procedure

1-Minute Promotional: SmartPads System Pipe Corrosion Protection