Industrial piping systems are subject to various dynamic forces, including thermal expansion, contraction, and vibration. These movements can cause significant friction between the pipes and their supports, leading to wear and tear, increased stress, and eventually, leaks. Slide plates, typically made from low-friction materials such as PTFE (Polytetrafluoroethylene) or graphite, play a crucial role in reducing friction at the interface between pipes and their supports. By allowing for smooth movement, slide plates help prevent stress concentrations and protect the integrity of the piping system. This article explores the technical aspects of slide plates, their applications, and how they contribute to leak prevention in industrial piping systems. It also highlights the solutions offered by RedLineIPS, a brand of Cogbill Construction, for effectively integrating slide plates into various support configurations.

Understanding Friction in Piping Systems

Friction occurs when two surfaces move against each other. In piping systems, friction between the pipe and its support can cause localized stress, wear, and material degradation over time. This is especially problematic in systems that experience significant movement due to thermal expansion, contraction, or vibration.

Causes of Friction in Piping Systems

- Thermal Expansion and Contraction: Pipes expand and contract with changes in temperature, causing axial and lateral movement. Without proper accommodation, this movement creates friction between the pipe and its supports, causing wear to the pipe’s protective paint coating and the pipe itself.

- Vibration: Mechanical vibrations from equipment like pumps and compressors can cause the pipe to oscillate against its supports, leading to abrasive wear and potential leaks.

- Dynamic Loads: Changes in flow rates, pressure, or fluid velocity can create dynamic forces that push the pipe against its supports, increasing friction and stress.

Example: In a high-temperature steam line, the thermal expansion of the pipe can cause it to move several inches along its length. If this movement is not accommodated by low-friction supports, it can lead to significant wear and tear on both the pipe and the support structure.

Impact of Friction on Piping Systems

- Wear and Tear: Wear and Tear: Continuous friction can erode the protective coatings on pipes and supports, exposing the underlying material to corrosion and increasing the risk of leaks.

- Stress Concentration: Friction can cause localized stress concentrations at points of contact, leading to cracks and structural failure over time.

- Joint and Seal Damage: Excessive friction can cause joints and seals to loosen or fail, resulting in leaks and potential environmental hazards.

The Function of Slide Plates

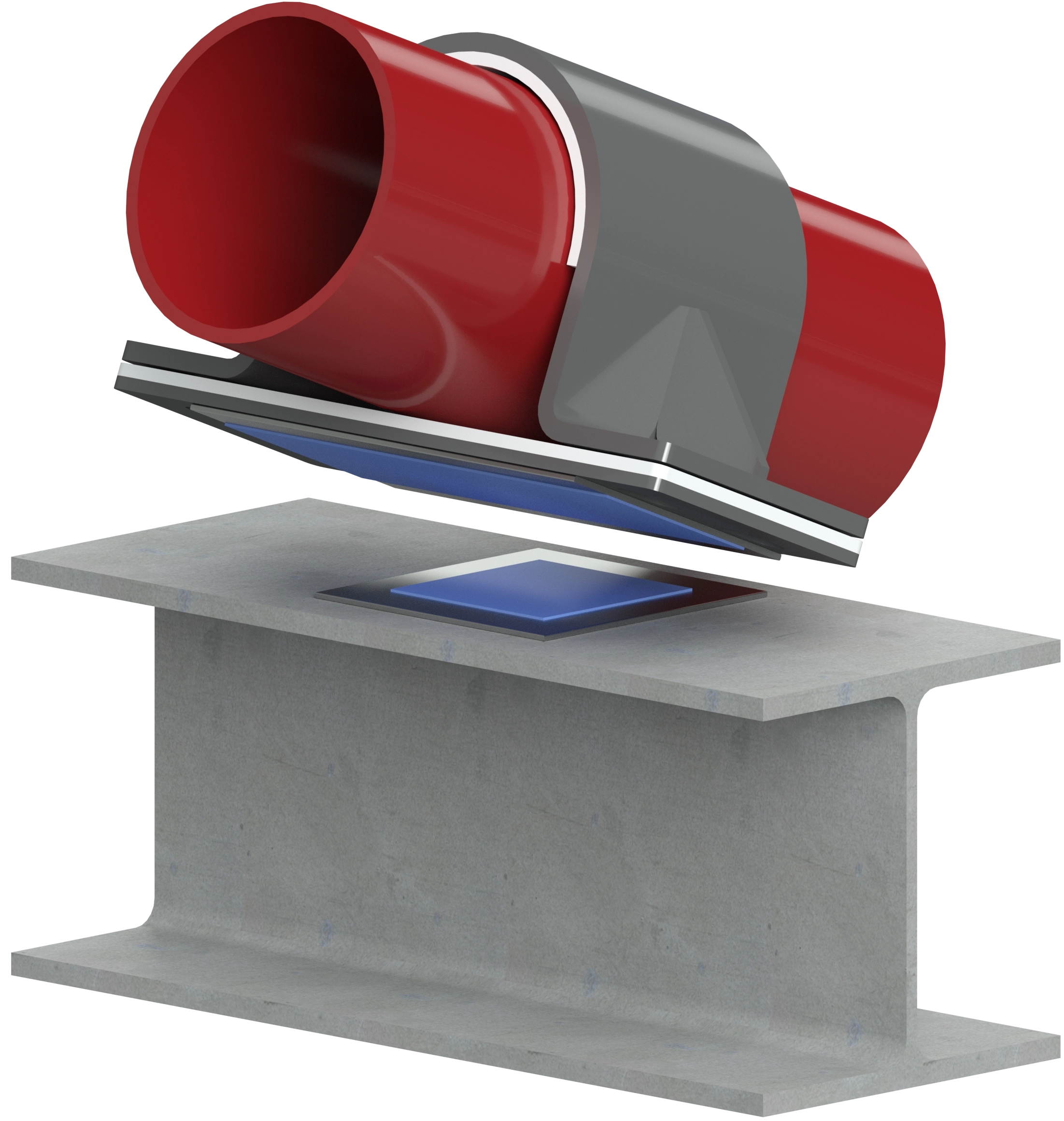

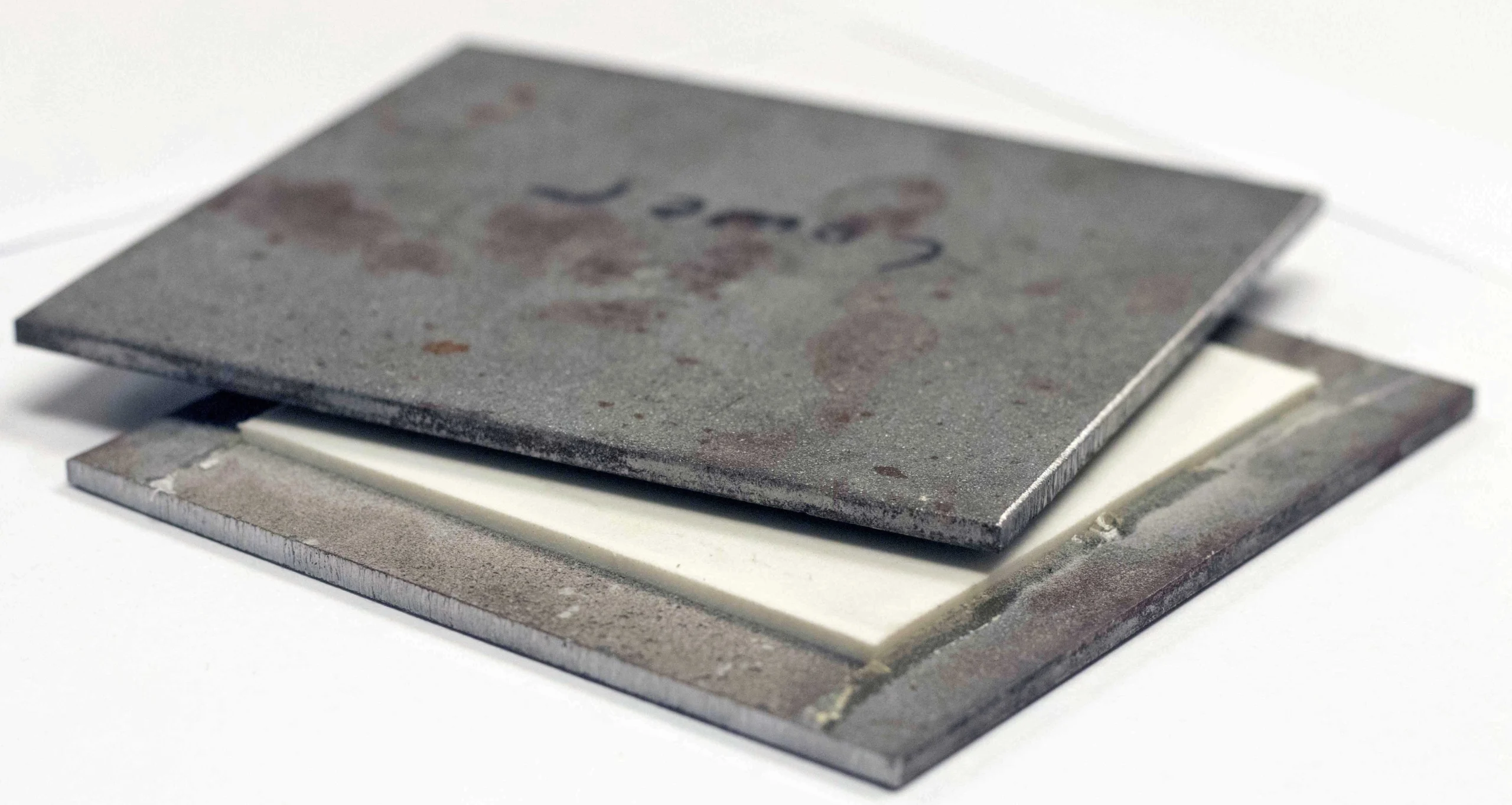

Slide plates are designed to reduce the friction between the pipe and its support, allowing for smooth movement and preventing stress build-up. They are typically made from materials with a low coefficient of friction, such as PTFE or graphite, and are installed at the interface between the pipe and its support.

Types of Slide Plates

- PTFE Slide Plates: PTFE, also known as Teflon, is a high-performance material with excellent chemical resistance and a very low coefficient of friction. PTFE slide plates are ideal for applications involving high temperatures and corrosive environments. PTFE coefficient of friction is around 0.05-0.1, and its maximum operating temperature is 260°C.

- Graphite Slide Plates: Graphite slide plates offer excellent high-temperature stability and are often used in applications where extreme heat is a concern. They are also resistant to chemical attack and have good load-bearing properties. Graphite has an excellent high-temperature tolerance of up to 450°C but requires lubrication in some conditions.

- Composite Slide Plates: These combine different materials, such as PTFE and stainless steel, to provide a balance of low friction, high strength, and durability. They combine properties like high compressive strength and low friction for heavy-load applications.

Benefits of Using Slide Plates

- Reduced Friction and Wear: Slide plates significantly reduce the frictional forces between the pipe and its support, minimizing wear and tear on both components.

- Improved System Longevity: By reducing stress and wear, slide plates extend the lifespan of the piping system and its supports, reducing the need for frequent maintenance and replacements.

- Enhanced Leak Prevention: By preventing stress concentrations and protecting joints and seals, slide plates help reduce the risk of leaks in dynamic piping systems.

Tip: Select slide plates based on the specific operating conditions of your piping system, including temperature, pressure, and chemical exposure, to ensure optimal performance and longevity.

Applications of Slide Plates in Piping Systems

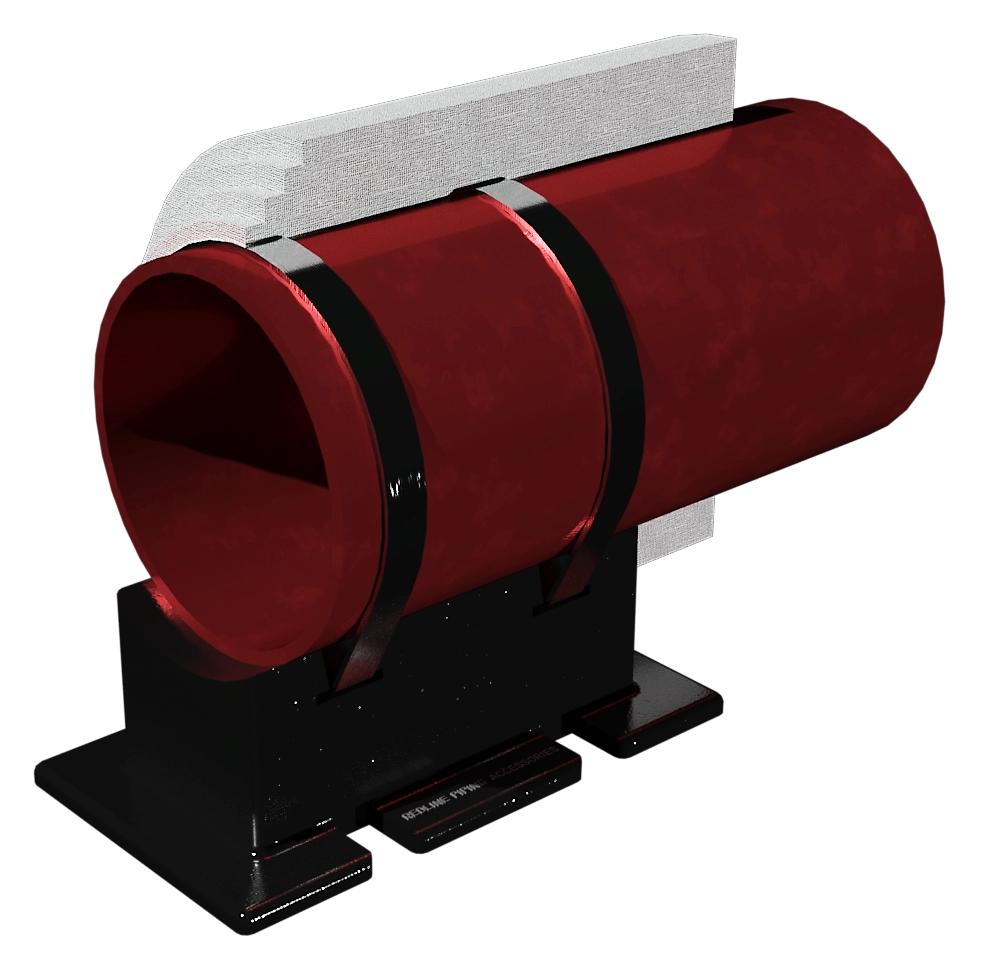

- Stable Support and Movement: Pipe shoes maintain the alignment of the pipe while allowing for smooth axial movement, reducing the risk of leaks and structural damage.

- Pre-Insulated Options: For cryogenic or high-temperature applications, pre-insulated pipe shoes with slide plates help maintain thermal stability and reduce energy loss.

Example: RedLineIPS offers pre-insulated pipe shoes with PTFE slide plates for use in cryogenic and high-temperature systems, ensuring both thermal insulation and friction reduction.

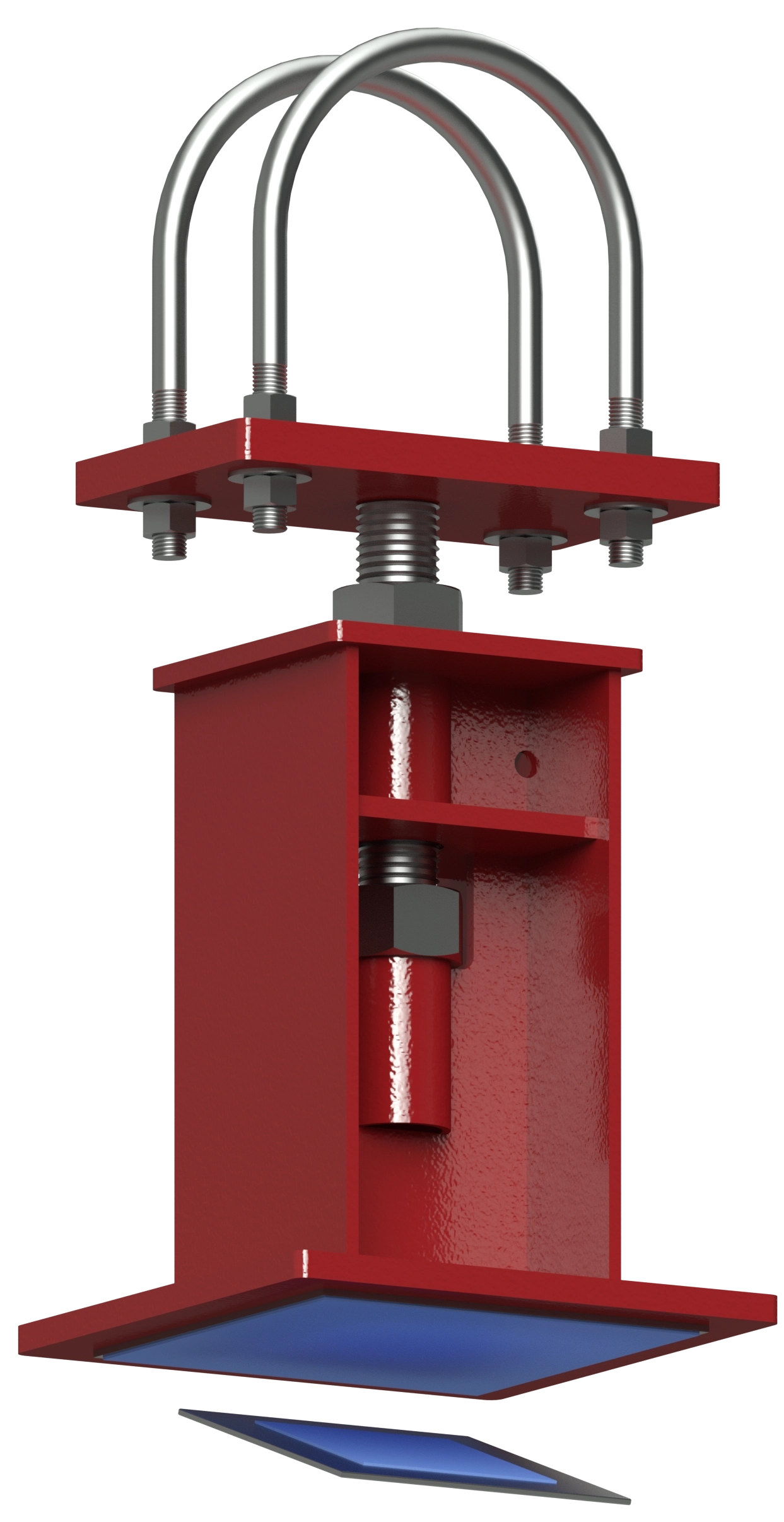

- Vibration Control: Slide plates in hold-down clamps reduce the impact of vibration on the pipe, preventing fatigue failures and leaks.

- Controlled Movements: The combination of hold-down clamps and slide plates allows for controlled axial movement, accommodating thermal expansion without compromising stability.

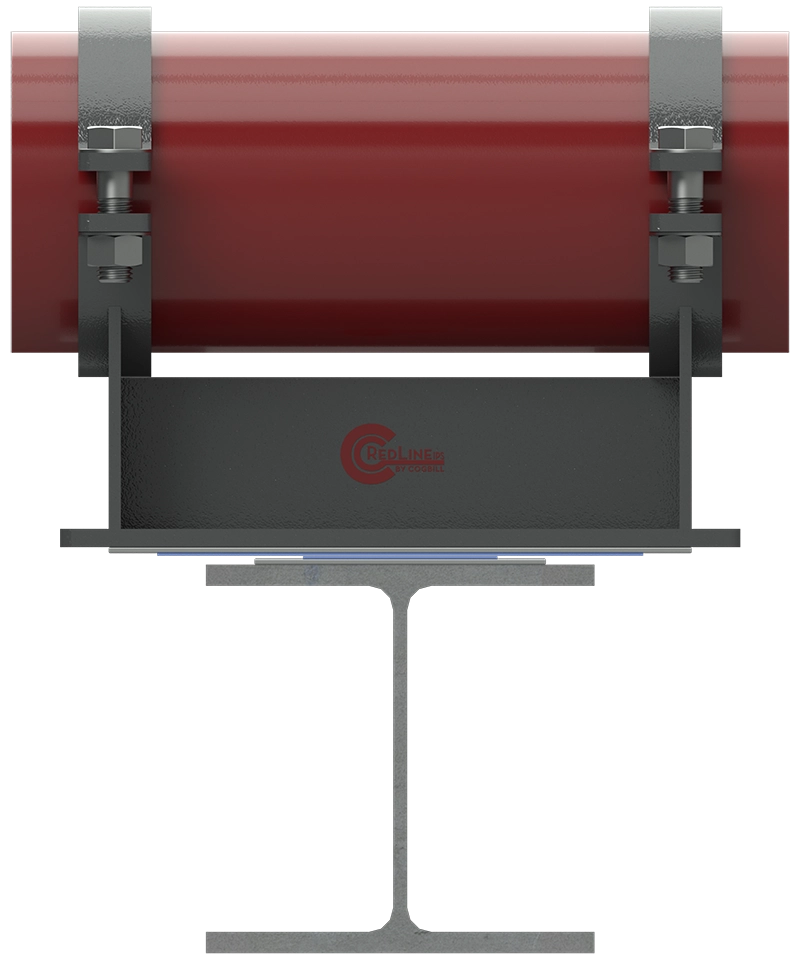

- Load-Bearing and Movement Accomedation: Slide plates in structural supports minimize friction at the interface, enabling smooth movement while securely holding the load. This reduces the risk of wear, misalignment, or damage to both the structure and the pipe.

- Customizable Materials for Varied Applications: Structural supports can be fitted with slide plates made of PTFE, graphite, or bronze to suit specific operating conditions such as high temperatures, cryogenic environments, or heavy industrial loads.

Best Practices for Using Slide Plates in Piping Systems

To maximize the effectiveness of slide plates in reducing friction and preventing leaks, it is essential to follow best practices during design, installation, and maintenance.

1- Design Considerations:

- Material Selection: Choose slide plates made from materials that match the operating conditions of the system, including temperature, pressure, and chemical exposure.

- Load Calculations: Ensure that the slide plates can handle the expected load and movement of the pipe. Oversized or undersized slide plates can lead to performance issues and potential damage.

- Placement Alignment: Properly align and place slide plates to ensure smooth movement and even load distribution. Misalignment can cause uneven wear and stress on the piping system.

Tip: Consult with RedLineIPS experts to select the appropriate slide plates and support configurations for your specific application.

2- Installation Guidelines:

- Secure Attachment: Ensure that slide plates are securely attached to both the pipe and the support structure. Loose slide plates can cause misalignment and increased friction.

- Correct Alignment: Use precision alignment tools to ensure that slide plates are installed in the correct position, allowing for smooth movement in the intended direction.

- Avoid Contamination: Keep the surface of the slide plates clean and free of debris during installation. Contaminants can increase friction and reduce the effectiveness of the slide plates.

Tip: Use protective covers or coatings on slide plates in harsh environments to prevent contamination and maintain performance.

3- Regular Maintenance and Inspection:

- Visual Inspections: Conduct regular visual inspections to check for signs of wear, damage, or misalignment. Look for scratches, gouges, or deformation of the slide plates.

- Lubrication: In some cases, periodic lubrication may be necessary to maintain the low-friction properties of the slide plates. Use lubricants compatible with the material of the slide plates and the operating environment.

- Replace Worn Components: Replace slide plates that show signs of excessive wear or damage to prevent increased friction and potential leaks.

Tip: Implement a maintenance schedule that includes periodic inspections and lubrication, especially in high-stress environments.

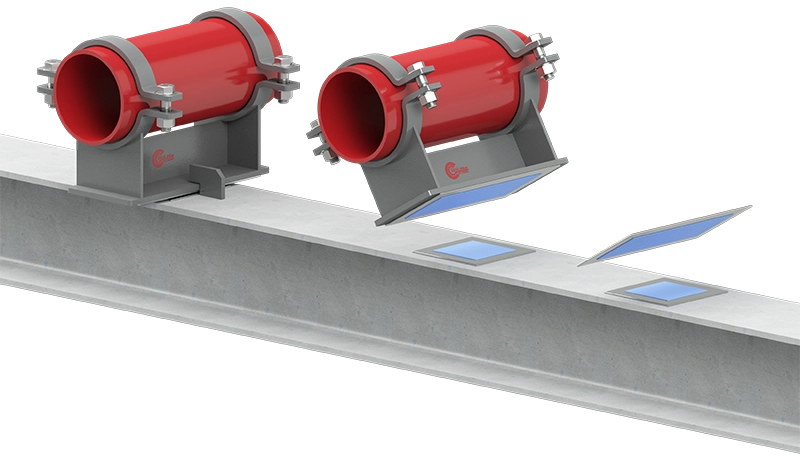

Integrated Slide Plates in Pipe Supports

For systems that require a complete support solution, RedLineIPS offers integrated slide plates in pipe supports, including sliding supports, pipe shoes, and hold-down clamps. These products provide both structural support and friction reduction in a single package.

- Pre-Insulated Options: Pre-insulated pipe shoes with integrated slide plates are available for cryogenic and high-temperature applications, providing both thermal insulation and movement accommodation.

- Heavy-Duty Designs: Supports with integrated slide plates are designed to handle heavy loads and significant movement, making them suitable for large-diameter and high-pressure systems.

Case Study: High-Temperature Steam Line

A power plant was experiencing frequent leaks and maintenance issues in a high-temperature steam line due to excessive friction between the pipe and its supports. The existing supports were not equipped with slide plates, causing significant wear and stress on the pipe. RedLineIPS provided a solution that included sliding supports with integrated PTFE slide plates.

- Solution Impact: The new sliding supports reduced friction and allowed for smooth thermal expansion and contraction, eliminating the stress concentrations that were causing leaks.

- Outcome: The plant reported a 60% reduction in maintenance-related downtime and improved system reliability due to the effective management of thermal movement and friction.

Slide plates are a vital component in managing friction and preventing leaks in industrial piping systems. By reducing friction at the interface between the pipe and its support, slide plates help prevent stress build-up, protect joints and seals, and extend the lifespan of the system. RedLineIPS, a brand of Cogbill Construction, offers a range of high-quality slide plate solutions designed to meet the unique challenges of various industrial applications. For more information on how RedLineIPS can help you integrate slide plates into your piping supports and prevent leaks, visit our Metallic Supports Page and our slide plates page.