The Evolution of Reinforcement Pad Design in Industrial Piping

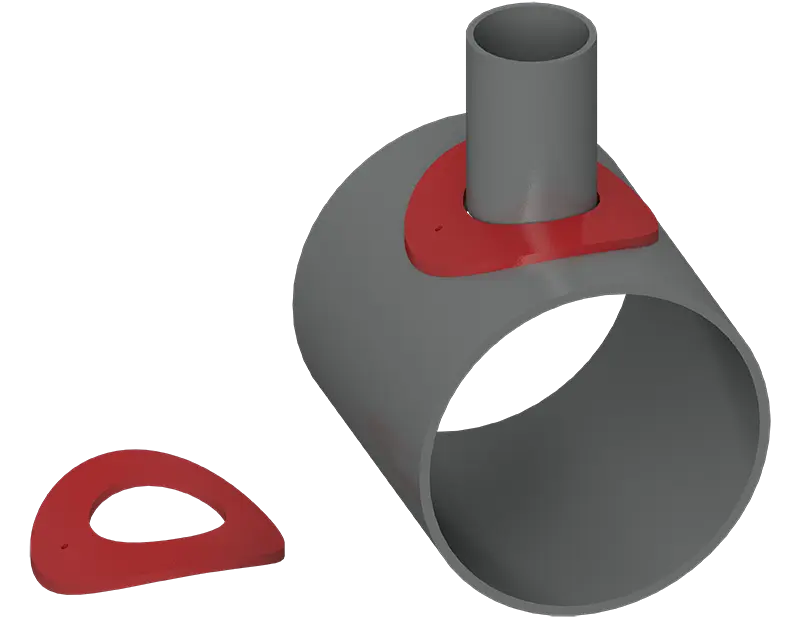

Reinforcement pads, commonly known as Repads, have been a staple in industrial piping systems for decades. Their primary function is to provide additional strength to areas of piping or vessels that are vulnerable to stress concentrations, particularly around branch connections, nozzles, and other penetrations in the pipe or vessel wall. As industrial processes have evolved, so too have the design and application of reinforcement pads. We will explore the history and evolution of reinforcement pad design, highlighting key advancements in materials, engineering practices, and the growing role of technology in enhancing the safety and reliability of industrial piping systems, as well as RedLineIPS reinforcing pads offerings.

The Early Days: Basic Reinforcement Concepts

The concept of reinforcing pipes at points of vulnerability is not new. In the early days of industrial piping, engineers recognized the need to strengthen areas where pipes were cut or penetrated to prevent failures. Initial reinforcement methods were rudimentary, often involving the use of extra metal plates or sleeves welded around the weakened sections. These early reinforcement pads were designed primarily with the goal of adding material to counteract the loss of strength caused by openings.

Challenges Faced:

- Material Limitations: Early reinforcement pads were often made from the same material as the pipe, typically carbon steel. However, these materials were susceptible to corrosion and other environmental factors, leading to premature failures.

- Welding Techniques: Welding technology in the early 20th century was less advanced, leading to inconsistent weld quality and increased risks of defects such as cracks or incomplete fusion, which could compromise the effectiveness of the reinforcement.

Mid-20th Century: The Standardization Era

As industrial processes became more complex, the need for standardized reinforcement solutions grew. During the mid-20th century, engineering standards and codes, such as those developed by the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API), began to emerge. These standards provided guidelines for the design and installation of reinforcement pads, ensuring a more consistent and reliable approach across the industry.

Key Developments:

- Standardization of Design: The introduction of engineering standards led to the development of standardized reinforcement pad designs, which could be applied across various industries and applications. This helped to reduce the variability in design and improve the overall safety and reliability of piping systems.

- Advancements in Materials: The use of more advanced materials, such as stainless steel and alloy steels, became more common during this period. These materials offered improved corrosion resistance and durability, making them better suited for harsh industrial environments.

The Late 20th Century: Integration of Advanced Engineering Practices

By the late 20th century, the design and application of Repads had become more sophisticated, driven by advancements in engineering practices and the increased use of computational tools. Finite element analysis (FEA) and other computer-aided design (CAD) tools allowed engineers to model the stresses and strains on piping systems more accurately, leading to more optimized reinforcement designs.

Key Advancements:

- Finite Element Analysis (FEA): FEA revolutionized the design of reinforcement pads by allowing engineers to simulate the stresses and strains on a pipe with a high degree of accuracy. This enabled the optimization of pad size, shape, and thickness, ensuring that the reinforcement was sufficient to handle the expected loads without being over-engineered.

- Custom Designs: The ability to model specific conditions and loads led to the increased use of custom reinforcement pad designs tailored to the unique requirements of each application. Custom pads could be designed to address specific challenges, such as high-temperature environments or corrosive conditions

The 21st Century: Embracing New Materials and Technologies

In the 21st century, the evolution of Repad design has been marked by the adoption of new materials and the integration of advanced technologies. As industries demand more from their piping systems, reinforcement pads have had to adapt to meet these challenges.

Innovations in Materials:

- Composite Materials: The use of composite materials, such as fiberglass-reinforced plastics (FRP) and carbon fiber composites, has become more common in certain applications. These materials offer high strength-to-weight ratios and excellent resistance to corrosion, making them ideal for environments where traditional metal pads might fail.

- High-Performance Alloys: The development of high-performance alloys, such as Inconel and Hastelloy, has expanded the range of environments where reinforcement pads can be effectively used. These alloys offer exceptional resistance to high temperatures and corrosive chemicals, making them suitable for extreme conditions.

Technological Integration:

- Smart Monitoring Systems: The integration of sensors and smart monitoring systems into reinforcement pads is an emerging trend. These systems can monitor the condition of the pad and the surrounding pipe in real-time, providing data on stress levels, temperature, and potential corrosion. This allows for predictive maintenance and early intervention before failures occur.

- 3D Printing and Additive Manufacturing: 3D printing and additive manufacturing technologies are beginning to make their mark in the production of reinforcement pads. These technologies allow for the creation of highly customized and complex pad designs that would be difficult or impossible to produce using traditional manufacturing methods

The Future: What Lies Ahead for Reinforcement Pad Design

The evolution of Repad design is likely to continue as new materials, technologies, and engineering practices emerge. Some potential future developments include:

- Advanced Material Science: Ongoing research in material science may lead to the development of even more advanced alloys and composites with superior strength, durability, and resistance to environmental factors.

- Increased Use of Automation: As the industrial sector continues to embrace automation, the design and installation of reinforcement pads may become more automated, improving precision and reducing the potential for human error.

- Ease of Installation and Maintenance: Supports should be easy to install and adjust, especially in environments where frequent maintenance is required. RedLineIPS designs their adjustable base ELL pipe supports for easy access and minimal maintenance, reducing downtime.

RedLineIPS Reinforcement Pads

At RedLineIPS, we specialize in the design and manufacturing of high-quality Repads tailored to meet the demanding requirements of various industrial applications. Our reinforcement pads are engineered using advanced materials and cutting-edge manufacturing techniques to ensure maximum durability, corrosion resistance, and structural integrity. We employ specialized CAD systems, precise CNC cutting equipment, skilled operators, and ASME-certified welders to produce reinforcing pads that fit your exact specifications. Whether you require standard or custom-designed pads, RedLineIPS offers a comprehensive range of solutions that adhere to the highest industry standards, including ASME and API guidelines.

Our commitment to quality and innovation means that we continuously adapt our products to incorporate new technologies to provide enhanced performance and reliability. With a focus on precision and customization, we are equipped to handle projects of any size, ensuring that our clients receive the most effective reinforcement solutions for their specific needs.

For more information about our reinforcement pad offerings and how we can support your industrial piping needs, visit RedLineIPS Reinforcement Pads.