Why hold‑down clamps matter

Walk any pipe rack and you’ll spot them everywhere: Π‑shaped hold‑down clamps bolted to beam flanges, gently pressing over the pipe. They’re easy to overlook until one is specified wrong. When that happens, lines walk, coatings scuff, inspections drag on, and costs snowball. Get the clamp right, though, and your piping stays seated through startups, shutdowns, wind, and pump trips—while still sliding axially for thermal growth.

What is a hold‑down clamp?

A hold‑down clamp is a vertical restraint. Its mission is simple: keep the pipe in contact with the support steel and prevent lift‑off or side‑walk, while allowing low‑friction axial movement when the line heats or cools. It is not an anchor, line stop, or snubber—the right clamp holds the line down without locking it in place.

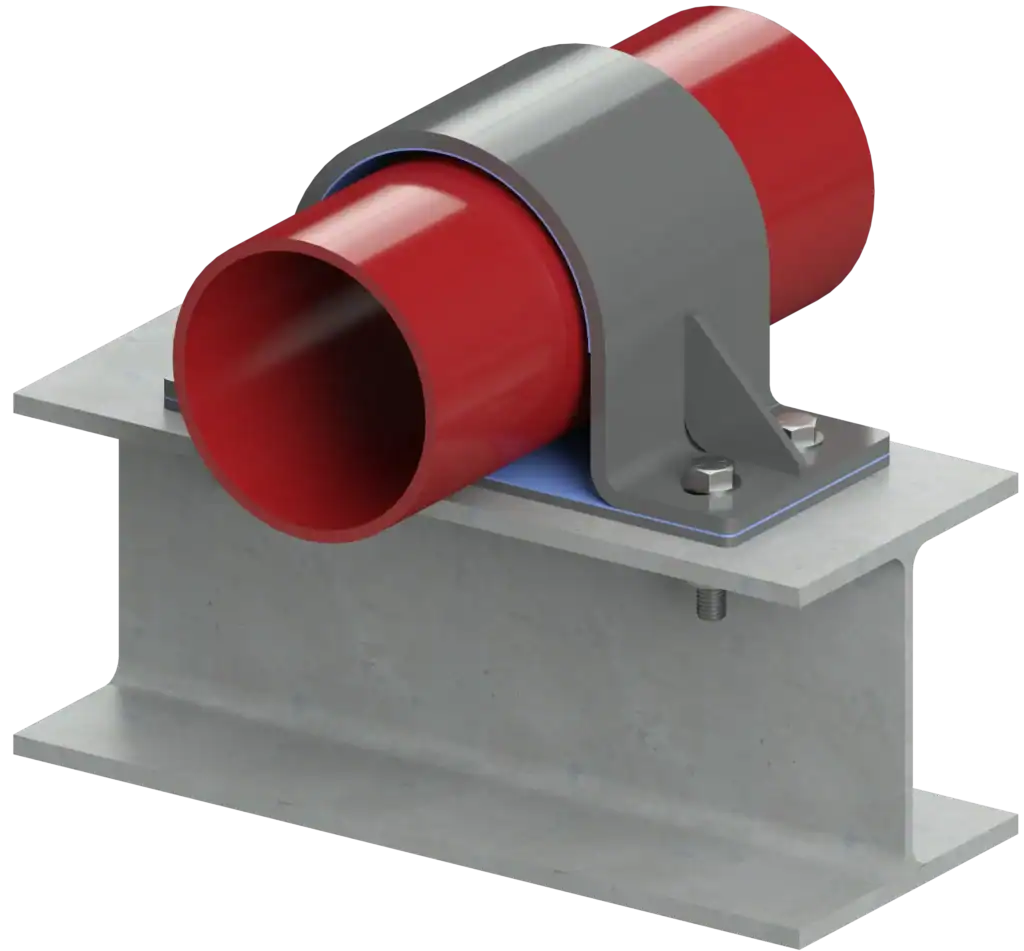

Anatomy of a proper hold‑down clamp

A solid hold-down clamp typically includes:

- A rolled crown (carbon steel or stainless) shaped to the pipe OD

- Two legs, or tabs, bolted to a base plate or beam flange

- Low‑friction, non‑metallic liner at the contact surface (PTFE/UHMW/FRP, etc.)

- Hardware: bolts, flat washers, prevailing‑torque nuts, and optional dielectric sleeves

- Optional gussets for large diameters or high‑vibration locations

Metal‑only clamps vs. modern isolated clamps

Traditional all‑metal clamps can unintentionally create classic corrosion‑under‑pipe‑support (CUPS) hot spots—there’s a metal‑to‑metal path and a place for moisture to linger. Modern practice pairs the clamp with isolation and low‑friction surfaces so the pipe stays seated, moves predictably, and stays dry at the interface.

At Cogbill Construction, under our RedLineIPS brand of piping products, we design and fabricate hold-down clamp packages that:

- Maintain a dielectric break between pipe and structure (helps curb galvanic CUPS)

- Use predictable, low‑friction liners so thermal growth doesn’t ratchet or gouge coatings

- Add damping where vibration is present and keep hardware tight under cycling

- Install cleanly with bolt‑in details—no field guesswork

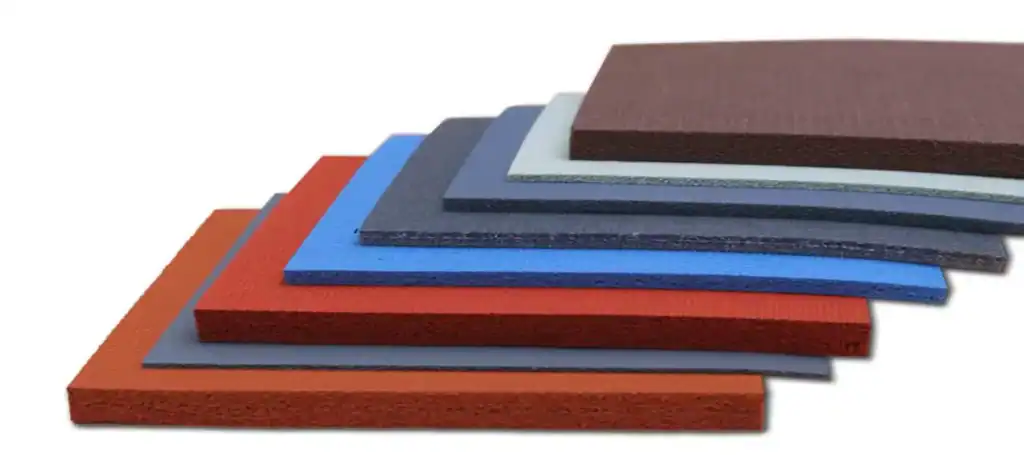

Isolation liners: quick guide

Pick the liner for temperature, chemistry, and the movement you expect:

- PTFE (virgin or 25% glass‑filled): Very low, stable friction for smooth axial slide; broad chemical resistance. Glass‑filled improves wear under load. Verify grade and temperature limits per vendor data.

- UHMW‑PE: Low friction at moderate temperatures with outstanding abrasion resistance; economical for long rack runs.

- FRP/phenolic isolation pad (e.g., G‑10/phenolic): Electrical isolation plus a tough bearing surface—useful where CUPS risk at supports is a concern.

- Elastomer pad (EPDM, NBR, silicone): Adds damping and a touch of micro‑sealing under the crown; select compound for temperature and media

Typical friction (ballpark):

- Bare steel on steel: 0.25–0.35 (variable)

- PTFE‑lined: 0.04–0.10 (predictable)

- UHMW‑PE: ~0.10–0.20 (surface dependent)

When to add gussets

If you’re dealing with large diameters (≈12”. and up), long bolt spans, persistent vibration, or credible uplift/wind/seismic loads, weld triangular gussets to stiffen the clamp legs. Gussets reduce flex under preload and improve how transient loads transmit into the support steel. Coordinate the gusset geometry with bolt access and liner coverage.

Field tips that save headaches

- Set elevation/alignment first. Tighten bolts evenly and in stages to avoid ovalizing the pipe.

- Clean the contact area; install liners flat (no grit, no wrinkles). Add sleeves/washers in the right order.

- Use locking hardware where vibration is present and record final torque if your spec requires it.

- Plan inspection access; the best clamp is one crews can check and re‑torque quickly.

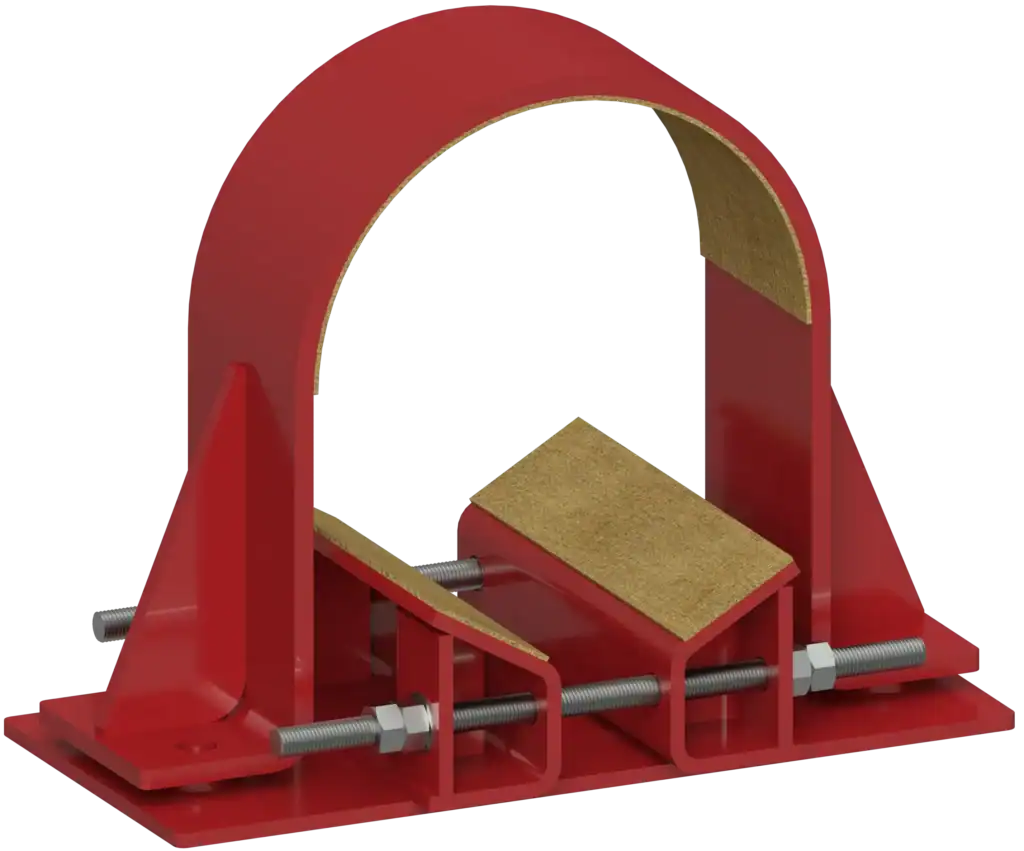

Shim Block Assembly

Sometimes, a hold-down clamp is paired with shim block assembly, which is a fixed-height spacer pack that sets the final elevation between the beam (or sole plate) and the pipe. Think of it as a precision “height adapter” that lets the clamp do its main job—keep the pipe seated—while the shim stack establishes the correct top-of-steel (TOS) to bottom-of-pipe (BOP) dimension. Typical components include a base/sole plate, a stacked shim block (steel packers or a machined block), a low- friction/isolating liner at the clamp crown (PTFE/UHMW + dielectric pads), and anchor bolts.

Engineers use shim block assemblies when the rack steel is out of level, when small elevation corrections are required after stress/thermal runs, or when a standard hold-down clamp would otherwise “bridge” over an uneven surface. On large diameters or high-uplift locations, the clamp legs may be gusseted to transfer transient loads cleanly into the shimmed base.

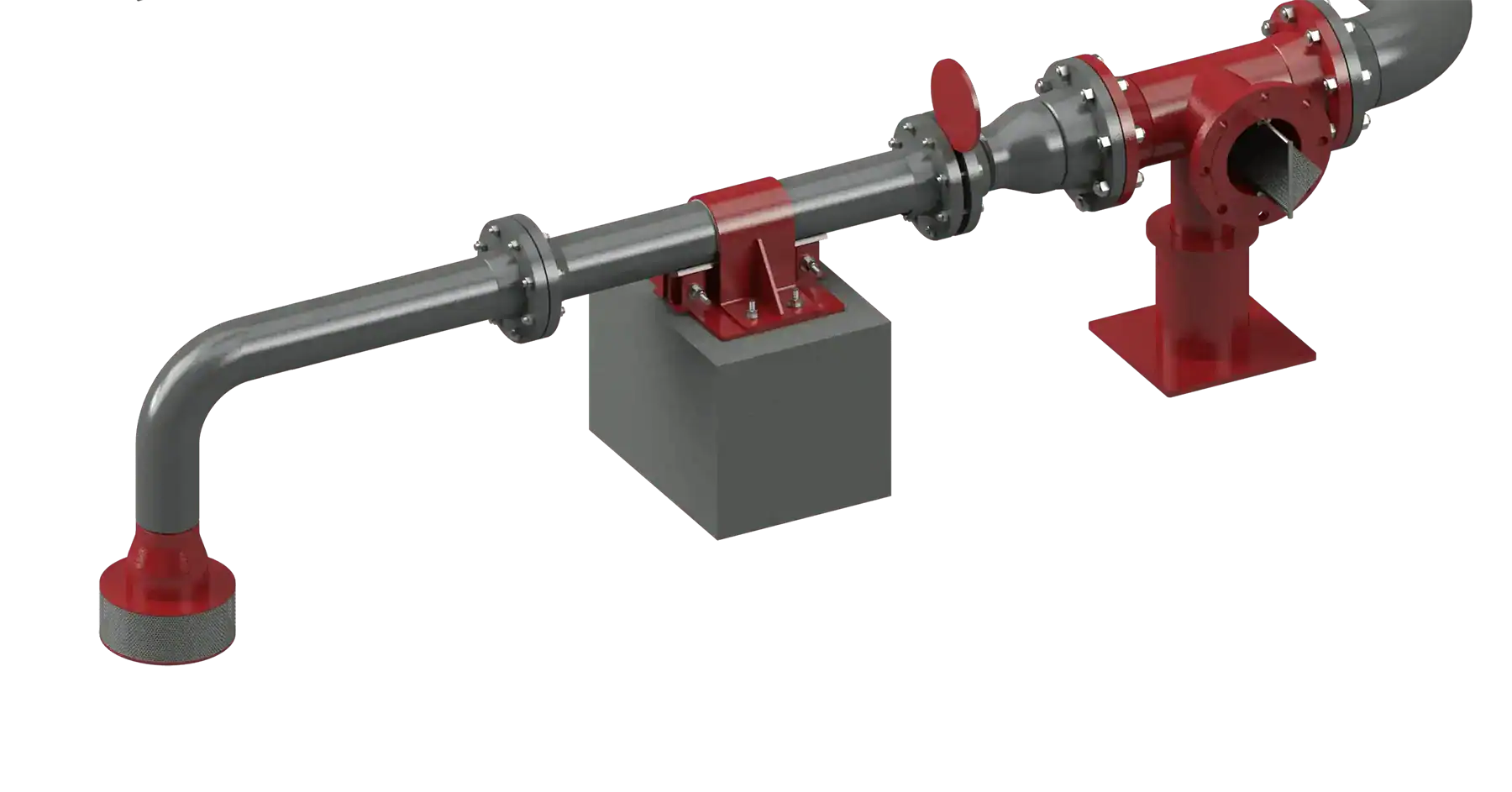

Where hold‑down clamps earn their keep

Pipe racks near anchors and expansion loops, pump and compressor bays, riser turns, and long hot runs (steam, condensate, hot hydrocarbons). In all these locations, a hold-down clamp keeps the line seated while the liner delivers the controlled slide your stress model expects.

Features of RedLineIPS hold down-clamps

- Fast, build‑to‑spec fabrication in carbon steel, stainless, and alloys

- Isolation‑ready clamp packages that address CUPS risk at the support

- Practical detailing for vibration areas (gusseted options, locking hardware, liner kits)

- Clear labeling and documentation to speed installation and inspection

A good hold‑down clamp costs a little; a failed support costs a lot. Specify the liner and finish wisely, add gussets when loads call for them, fabricate cleanly, and tighten evenly. Do that, and this small restraint will keep big piping honest for years.

Need help selecting liners or adding isolation? Cogbill Construction build a quality hold-down clamp package for your service, temperature, and movement. Visit www.RedLineIPS.com or email Info@RedLineIPS.com.