In the petrochemical industry, vibration and noise control in industrial piping is a critical aspect of maintaining system integrity, efficiency, and safety. Excessive vibration and noise can lead to operational downtime, equipment damage, pipe fatigue, and safety hazards. At RedLineIPS, we offer a comprehensive range of pipe support solutions and isolation products that are specifically designed to mitigate these issues.

This guide explores the vibration and noise control solutions offered by RedLineIPS, explaining how they function within industrial piping systems to reduce wear, prevent failures, and ensure long-term durability.

Why Vibration and Noise Control in Industrial Piping Matters

Vibration and noise are byproducts of mechanical forces, fluid flow, and operational factors in industrial settings. Uncontrolled vibration can lead to:

- Fatigue damage to pipes, fittings, and equipment.

- Increased maintenance costs due to premature wear and tear.

- Operational inefficiencies, which can compromise system performance and lead to unplanned downtime.

- Noise pollution, creating an unsafe work environment for personnel.

Mitigating these forces requires an understanding of how vibration and noise isolation products work and which components are necessary to keep the system functioning at its best.

RedLineIPS Vibration and Noise Control Solutions

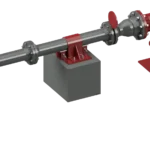

At RedLineIPS, we specialize in designing and fabricating pipe supports and isolation systems to address these challenges. Our solutions include pipe shoes, clamps, hangers, hold-down clamps with shim block assemblies, adjustable supports, non-adjustable supports, and isolation liners, all designed to reduce vibration and noise in industrial piping systems.

-

RedLineIPS Pipe Shoes with Isolation Liners

Pipe shoes are an integral part of industrial piping systems, supporting the pipes while allowing for controlled movement. They prevent excessive wear by reducing friction between the pipe and the structure, but when integrated with isolation liners, they provide an additional layer of protection against vibration and noise.

Key Features of RedLineIPS Pipe Shoes:

- Material Versatility: Our pipe shoes are available in carbon steel, stainless steel, and alloy materials, ensuring durability and suitability for a variety of industrial applications.

- Vibration Dampening: RedLineIPS pipe shoes can be fitted with rubber pads, composite liners, or elastomeric materials to absorb vibration and prevent it from transferring to the structure. These liners act as buffers between the pipe and the support, significantly reducing the wear caused by friction and vibration.

- Thermal Expansion Management: Our shoes also allow for controlled movement due to thermal expansion and contraction, helping prevent stress on the piping system.

By integrating isolation liners, RedLineIPS pipe shoes ensure minimal vibration transmission, leading to quieter, more stable operations. Explore more about our products at RedLineIPS Pipe Shoes.

- Adjustable and Non-Adjustable Pipe Supports

Proper support is essential in reducing pipe movement, which is one of the main causes of vibration and noise in industrial systems. RedLineIPS adjustable and non-adjustable supports offer a versatile range of solutions to accommodate various load requirements and system configurations.

A. Adjustable Pipe Supports

Adjustable pipe supports allow for fine-tuning and height adjustment, ensuring proper alignment of the piping system. This is especially important in managing systems that are subject to thermal expansion, which can lead to pipe stress and vibration.

- Customizable Height: Our adjustable supports allow for easy changes in height to ensure accurate alignment and to maintain proper load distribution.

- Isolation Liners: We integrate various non-metallic isolation liners—such as neoprene, rubber, and composite materials—into these supports to reduce vibration and noise, as well as prevent metal-to-metal contact that could lead to wear.

Explore more about our adjustable pipe supports at RedLineIPS Adjustable Pipe Supports.

B. Non-Adjustable Pipe Supports

For static or less variable piping configurations, RedLineIPS non-adjustable supports are engineered for optimal stability and load-bearing capacity.

- Durable Construction: Our non-adjustable supports are built from high-quality metals and can be equipped with isolation pads to absorb shocks and vibrations.

- Fixed Positioning: These supports provide consistent, secure positioning to ensure that the pipes remain stable during operation, preventing excessive vibration from fluid dynamics and mechanical forces.

- RedLineIPS Pipe Clamps and Hangers

Pipe clamps and hangers are essential for securing pipes and preventing unwanted movement that can lead to vibration and noise. RedLineIPS provides a range of pipe clamps and hangers designed for industrial applications, offering robust solutions for securing pipes in both horizontal and vertical configurations.

A. Pipe Clamps with Isolation Features

RedLineIPS pipe clamps are available with isolation inserts such as rubber pads, fiberglass liners, and elastomeric materials that isolate the pipe from the clamp structure, preventing the transfer of vibration.

- Vibration Isolation: The incorporation of liners within the clamps reduces the direct transmission of vibrational forces between the pipe and the support structure.

- Preventing Corrosion and Wear: By isolating the pipe from the clamp, the liner also protects against galvanic corrosion and reduces wear on both the pipe and the clamp.

B. Pipe Hangers for Vertical Stability

Our pipe hangers are designed for suspending pipes from overhead structures, offering strong support while minimizing vibration.

- Flexible Mounting: Hangers come with a variety of mounting options and are equipped with non-metallic inserts to dampen vibration in vertical configurations.

- Noise Reduction: When combined with the proper isolation materials, pipe hangers also help reduce noise caused by fluid flow or mechanical vibration.

For more information on our pipe clamps and hangers, visit RedLineIPS Pipe Clamps.

- Shim Block Assemblies with Integrated Isolation

Shim block assemblies play a crucial role in leveling and aligning pipes while providing vibration control. RedLineIPS offers shim block assemblies equipped with isolation pads that prevent the transmission of vibrational energy from the piping system to the support structure.

Key Features:

- Load Distribution: Shim block assemblies are designed to distribute loads evenly, reducing stress points in the piping system.

- Custom Configurations: RedLineIPS provides custom shim block assemblies to meet the specific needs of your industrial piping system.

- Preventing Corrosion and Wear: By isolating the pipe from the clamp, the liner also protects against galvanic corrosion and reduces wear on both the pipe and the clamp.

For more information, explore our shim block assembly solutions at RedLineIPS Shim Block Assembly.

- Isolation Liners and Vibration Control Pads

At the heart of our vibration and noise mitigation solutions are our isolation liners and vibration control pads. These components are integral to the performance of pipe supports in demanding industrial environments. The right isolation material can make a significant difference in reducing the transmission of vibrational energy through the piping system. At RedLineIPS we offer a wide array of isolation liners, among them are:

A. Nitrile Rubber

- Composition: Nitrile rubber, also known as Buna-N, is a synthetic rubber made from acrylonitrile and butadiene.

- Properties: Nitrile rubber is known for its excellent resistance to oils, grease, fuels, and various chemicals, making it suitable for environments where chemical exposure is common. It also offers superior flexibility and shock absorption, making it highly effective at dampening vibrations. Note: NBR has limited ozone/UV resistance—shield or specify for covered service areas.

- Applications: Nitrile rubber is ideal for industrial environments like refineries, chemical plants, and oil and gas facilities. It’s frequently used in pipe supports, where the combination of vibration control and chemical resistance is critical.

B. Cotton Duck Pads

- Composition: Made from multiple layers of cotton duck fabric, which is a tightly woven heavy-duty cotton material. These layers are typically impregnated with rubber to enhance durability and vibration dampening properties.

- Properties: Cotton duck pads are excellent at mitigating vibration and absorbing shocks. The fabric structure allows them to conform to surfaces and provide a non-conductive barrier between metal components, helping to reduce galvanic corrosion in addition to isolating vibration.

- Applications: Cotton duck pads are frequently used in metallic pipe supports, particularly at points where pipes come into contact with metal shoes, clamps, or hangers. They are highly effective in reducing crevice corrosion and vibration, and are widely used in offshore platforms, chemical plants, and power generation facilities.

C. EPDM (Ethylene Propylene Diene Monomer)

- Composition: EPDM is a synthetic rubber derived from ethylene and propylene, with a small amount of a diene monomer to allow for cross-linking and vulcanization.

- Properties: EPDM is highly resistant to weathering, UV radiation, ozone, and extreme temperatures. It offers excellent vibration dampening while maintaining flexibility over a wide temperature range. Its resistance to water and steam makes it particularly well-suited for applications involving high moisture.

- Applications: EPDM is often used in outdoor applications or in environments where pipes are exposed to weather or moisture. It is particularly effective in many steam and hot-water services and power plants, as well as other high-temperature applications where both thermal stability and vibration control are required. EPDM is not recommended for oils/greases; use NBR/neoprene when hydrocarbon exposure is expected.

D. Neoprene

- Composition: Neoprene is a chloroprene-based synthetic rubber that provides excellent flexibility and resilience in a variety of environments.

- Properties: Neoprene is well-known for its chemical resistance to oils, greases, and mild acids, as well as its ability to withstand moderate temperatures (typically ~200°F/93°C continuous). It is also effective in reducing vibration and shock, with high elasticity that helps dissipate mechanical energy.

- Applications: Neoprene is frequently used in chemical plants, oil refineries, and industrial piping systems that require both vibration isolation and chemical resistance. It’s a versatile material that performs well in both indoor and outdoor environments, especially in settings where high temperatures and exposure to oils are a concern.

E. Fabreeka® Pads

- Composition: Fabreeka pads are made from reinforced elastomeric materials embedded with layers of cotton duck fabric for added strength and durability.

- Properties: These pads provide outstanding vibration isolation and shock absorption. The combination of rubber and fabric layers allows Fabreeka pads to absorb energy effectively, preventing the transmission of vibration and reducing noise. They are highly durable and capable of handling heavy loads without losing their isolation capabilities.

- Applications: Fabreeka pads are commonly used in heavy-duty industrial applications, including the supports of large machinery, piping systems, and equipment foundations. They are especially valuable in environments where machinery generates significant vibrations and impacts, such as power plants and manufacturing facilities.

Each of these liners is specifically designed to isolate the pipe from the support structure, preventing vibration transmission and significantly reducing noise. For more details, visit our pipe liner page at RedLineIPS Isolation Liners.

- Snubbers, Spring Supports, and Additional Solutions

In addition to our wide range of pipe support products, RedLineIPS also supplies snubbers, spring supports, and other components to help control dynamic forces and vibration in industrial piping systems.

A. Snubbers

Snubbers are used to control sudden movement in piping systems, often caused by seismic activity or large-scale operational shifts. They offer dynamic restraint and are ideal for environments where piping systems are subject to shocks or quick shifts in load.

B. Spring Supports

Spring supports offer flexibility in managing dynamic loads, accommodating the expansion and contraction of piping systems while dampening vibration. These supports ensure stable operation even in systems with variable conditions.

In summary, vibration and noise control in industrial piping is crucial for ensuring safety, reducing maintenance costs, and improving system longevity. At RedLineIPS, we offer a wide range of pipe supports, isolation liners, and complementary products designed to mitigate these issues.

Whether you’re dealing with fluid dynamics, mechanical equipment vibration, or environmental factors, our solutions—including pipe shoes, clamps, hangers, and adjustable supports—are engineered to provide optimal performance.

For more information on how RedLineIPS can help you manage vibration and noise in your industrial systems, email us at Info@RedLineIPS.com.