Clambrace is an innovative pipe support guide system designed to secure various pipe supports and attachments to structural beams without the need for welding, drilling, or epoxy. This hot-dip galvanized solution preserves beam integrity and offers a fast, flexible, and corrosion-resistant method for quickly and safely installing various types of pipe supports onto beams.

Revolutionizing Pipe Support Attachment

No Welding, No Drilling, No Corrosion, Fully Movable

At Cogbill Construction, under the RedLineIPS brand, we are proud to exclusively offer Clambrace products from Clambrace, Belgium, across North America. Clambrace represents an innovative advancement in piping support technology, offering unparalleled flexibility, efficiency, and corrosion protection. By eliminating the need for invasive installation techniques like welding, drilling, or epoxy, Clambrace maintains the structural integrity of supporting beams while significantly reducing installation time and costs.

Engineered for industrial facilities across sectors like petrochemicals, oil and gas, power generation, and chemical processing, Clambrace is the ideal solution for modern, sustainable operations. Its versatility and durability make it an indispensable tool for improving efficiency and minimizing downtime.

How Clambrace Works

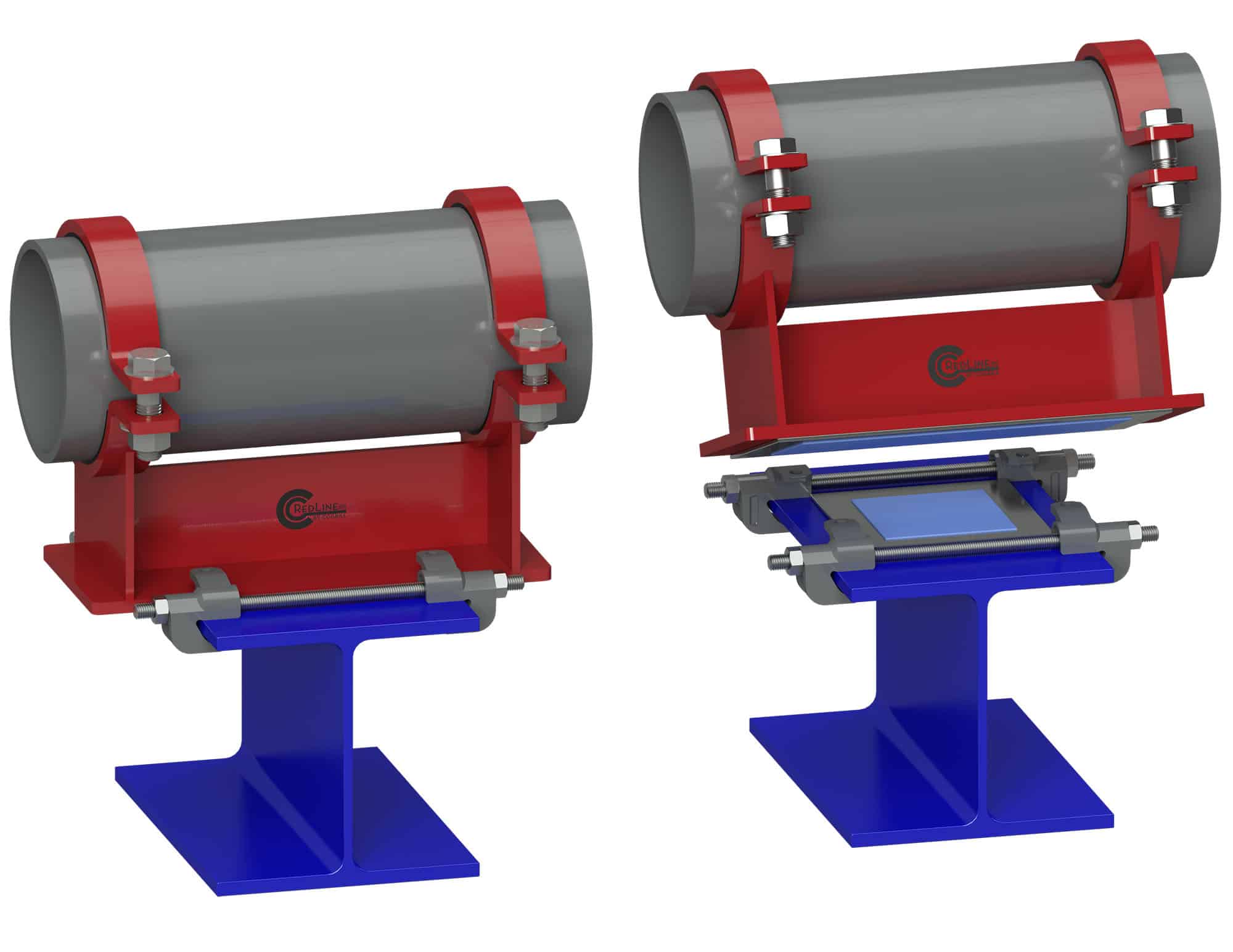

Clambrace is constructed from four forged steel corner pieces that are hot-dip galvanized, that clamp onto a structural beam without penetrating or damaging it. The installation process involves:

- Positioning the Corners: Two Clambrace corner sets are placed on opposite sides of the beam, each designed to grip securely.

- Connecting with Threaded Rods: Galvanized threaded rods are inserted through designated holes in the corner pieces, linking the two sets over the beam.

- Securing with Bolts: Bolts are tightened onto the threaded rods, fastening the Clambrace assembly firmly in place.

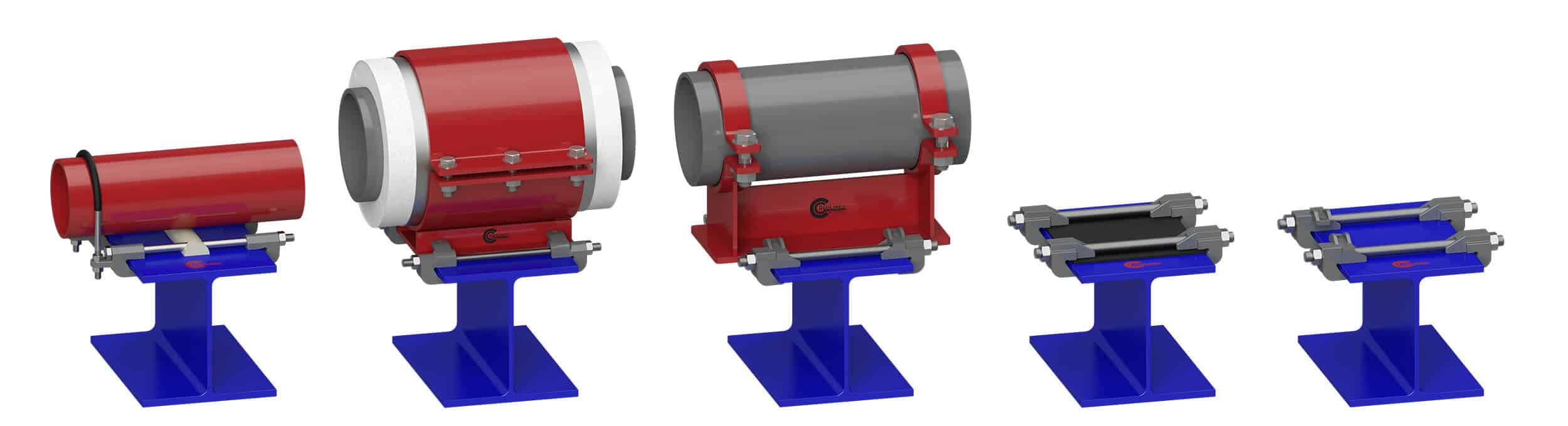

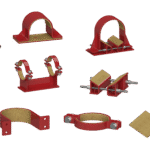

This configuration allows for the attachment of various pipe supports, such as pipe shoes, slide plates, flat FRP wear pads, and more, without the need for welding, drilling, or epoxy. Additionally, FRP wear pads, thermoplastic half-rods or a variety of non-metallic liners can also be used to serve as protective separators between the pipe and the beam, reducing friction and preventing metal-to-metal contact.

Key Benefits

- Quick Installation: Simplified assembly reduces labor time and associated costs.

- Non-Invasive Installation: Securely attaches to beams without welding or drilling, preserving structural integrity.

- Corrosion Resistance: Fully hot-dip galvanized components ensure durability in harsh, corrosive industrial environments, especially coastal and offshore installations.

- Enhanced Ventilation: Design promotes airflow around the pipeline, reducing moisture buildup and minimizing crevice corrosion risk.

- Versatility: Supports the attachment of various pipe supports including pipe shoes, clamps, flat FRP wear pads, PTFE slide plates, and more.

- Adjustability and Reusability: Easily movable and reusable, allowing for quick adjustments and repositioning, as needed.

Technical Specifications

- Materials: Galvanized forged steel corners, hot-dip galvanized threaded rods, and bolts.

- Beam Compatibility: Designed to fit standard American I-beam sizes ranging from W4x13 to W12x40.

- Threaded Rods: Conform to ASTM A307 Grade A standards, fully hot-dip galvanized for enhanced corrosion resistance.

- Load Capacity: Engineered to support heavy-duty industrial piping applications; specific load ratings available upon request.

- Installation Flexibility: System allows for easy loosening and repositioning without the need to remove existing pipe supports.

Ideal Applications and Industries

- Oil and Gas Pipelines: Facilitates non-permanent pipe support attachments, preserving pipeline integrity.

- Refineries and Petrochemical Plants: Allows for flexible support configurations without compromising structural components.

- Power Generation Facilities: Supports quick and safe installation in environments with stringent safety standards.

- Water and Wastewater Treatment Plants: Provides corrosion-resistant solutions suitable for high-moisture areas.

- Industrial Manufacturing: Offers adaptable and movable support systems for dynamic production settings.

Seamless Integration with RedLineIPS Solutions

Clambrace complements RedLineIPS offerings by providing a robust method to attaching pipe shoes, cryogenic shoes, pipe clamps, round or flat FRP wear pads, thermoplastic D-rods, non-metallic liners, PTFE slide plates, or other protective surfaces, to structural beams, quickly and easily, without the use of welding, drilling, or adhesives. This integration enhances corrosion protection and extends the lifespan of piping systems.

Clambrace vs. Traditional Methods

| Feature | Clambrace | Traditional Welding/Drilling |

|---|---|---|

| Installation Time | Quick and efficient | Time-intensive, labor-heavy |

| Specialized Labor | No | Yes, certified welders |

| Weather Dependence | Can be installed anytime | Requires dry conditions |

| Structural Integrity | Preserved | Compromised by drilled holes |

| Corrosion Resistance | Galvanized, rust-proof | Prone to rust without touch-ups |

| Flexibility | Easily adjustable | Fixed, permanent installations |

| Hot Work Permits | Not Required | Required for welding |

Get Clambrace Today

Enhance the reliability and flexibility of your piping systems with Clambrace by Hanwell, now available in North America exclusively through RedLineIPS. Contact us today to learn more about how Clambrace can improve.

Clambrace products are available exclusively through Cogbill Construction under the RedLineIPS brand for all of North America. Contact us today to learn more or request a customized solution.

- Email: Info@RedLineIPS.com

- Website: https://RedLineIPS.com/metallic-piping-supports/clambrace

- Phone: (409) 768-1419

- Location: 2325 S. Main St. Vidor, Texas 77662 U.S.A.