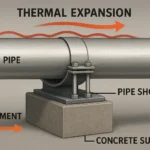

In high-risk industries such as petrochemical processing, oil and gas, and chemical manufacturing, piping systems are subject to high thermal loads, corrosive exposure, and severe dynamic operating conditions. Traditional welded pipe supports rigidly fix the pipe to structural members, often preventing natural axial movement caused by thermal expansion or contraction. When expansion is restrained in this way, internal stresses can accumulate, leading to coating damage, deformation, fatigue, or joint failure.

By contrast, non-welded pipe supports—such as clamped pipe shoes, slide plates, and saddle supports, for example,—are designed to allow axial movement while maintaining vertical and lateral stability. These supports accommodate thermal cycling, reduce stress at restraint points, help maintain pipe alignment and coating integrity, and significantly improve safety in hazardous environments.

This article outlines the technical principles, material options, and field applications of non-welded supports, using solutions from RedLineIPS as a reference for modern engineered design in hazardous environments.

Introduction

In many industrial settings, such as petrochemical plants and offshore platforms, the installation and maintenance of piping systems pose unique challenges, particularly in hazardous environments. Welding, while a common method for securing pipe supports, can be risky or impractical in these conditions due to the presence of flammable gases, liquids, and the need for hot work permits. Non-welded pipe supports offer a safer, more flexible alternative that eliminates the need for on-site welding, reducing safety risks and installation time. We will explore the benefits and applications of non-welded pipe supports, highlighting their role in maintaining safety and efficiency in hazardous environments.

The Risks of Welding in Hazardous Environments

Welding is a common method for securing pipe supports in many industrial applications. However, in hazardous environments, it presents several significant risks:

- Fire and Explosion Hazards: The heat and sparks generated by welding can ignite flammable gases or liquids, posing a severe risk of fire or explosion. This is particularly dangerous in environments such as oil refineries, chemical plants, and offshore platforms where volatile substances are present.

- Health and Safety Concerns: Welding produces harmful fumes and gases that can pose health risks to workers, especially in confined spaces or poorly ventilated areas. In addition, the need for hot work permits and additional safety measures can complicate the installation process.

- Increased Installation Time and Costs: The safety precautions required for welding, including the cost of skilled welders, hot work permits, fire watches, and specialized safety equipment, can significantly increase the time and cost of installation. These constraints make it difficult to perform quick or emergency repairs, potentially leading to prolonged downtime.

Advantages of Non-Welded Pipe Supports

Non-welded pipe supports eliminate the need for on-site welding, providing a range of benefits that make them ideal for hazardous environments:

- Enhanced Safety: By removing the need for hot work, non-welded supports significantly reduce the risk of fire and explosion. This makes them safer for use in environments with flammable gases or liquids, such as oil and gas facilities, chemical plants, and pharmaceutical manufacturing units.

- Faster Installation and Maintenance: Non-welded supports can be installed quickly and easily without the need for highly skilled labor or specialized equipment or permits. This reduces installation time and allows for faster, more efficient maintenance and repairs, minimizing downtime.

- Flexibility and Adjustability: Non-welded supports, such as hold-down clamps, clamped-on pipe shoes, or adjustable pipe supports, offer greater flexibility and adjustability compared to welded supports. They can be easily repositioned or adjusted to accommodate changes in the piping system, such as thermal expansion or alignment issues.

- Reduced Corrosion Risk: Welded joints are often prone to corrosion due to the heat-affected zone (HAZ) created during welding. Non-welded supports eliminate this issue, reducing the risk of corrosion and extending the lifespan of the piping system.

Types of Non-Welded Pipe Supports

Several types of non-welded pipe supports are available, each designed to meet specific requirements and applications, among them are:

- Clamped Pipe Supports: Clamped pipe supports use mechanical clamps to secure the pipe to the support structure. They are ideal for applications where quick installation and easy maintenance are required. Clamped supports can be used in a variety of configurations, including saddle supports, hold-down clamps and U-bolt clamps, which provide secure, non-welded attachment points.

- Slide Plates: Slide plates are used in conjunction with clamped or resting supports to accommodate thermal expansion by allowing pipes and their supports to move horizontally with minimal resistance. They are typically composed of low-friction materials such as PTFE (with a coefficient of friction as low as 0.05) or graphite, which reduce surface wear and help preserve protective coatings. By enabling smooth axial movement, slide plates prevent stress buildup at restraint points and are essential in systems exposed to temperature fluctuations or long pipe runs where expansion and contraction are expected.

Applications of Non-Welded Pipe Supports

Non-welded pipe supports are particularly beneficial in the following hazardous industrial environments:

- Oil and Gas Facilities: In oil refineries, offshore platforms, and petrochemical plants, non-welded supports reduce the risk of fire and explosion, making them a safer choice for securing piping systems in these volatile environments.

- Chemical Processing Plants: Chemical plants often handle corrosive and flammable substances that can pose significant risks during welding. Non-welded supports eliminate these risks and offer corrosion-resistant options, such as composite supports, for added durability.

- Pharmaceutical Manufacturing: In pharmaceutical manufacturing, cleanliness and safety are paramount. Non-welded supports provide a clean, safe, and efficient method for securing piping systems without introducing contaminants or health hazards associated with welding.

- Water Treatment and Desalination Plants: Non-welded supports are ideal for environments with high humidity and exposure to chemicals, such as water treatment and desalination plants. They resist corrosion and can be easily adjusted or replaced without the need for welding.

RedLineIPS Non-Welded Pipe Support Solutions

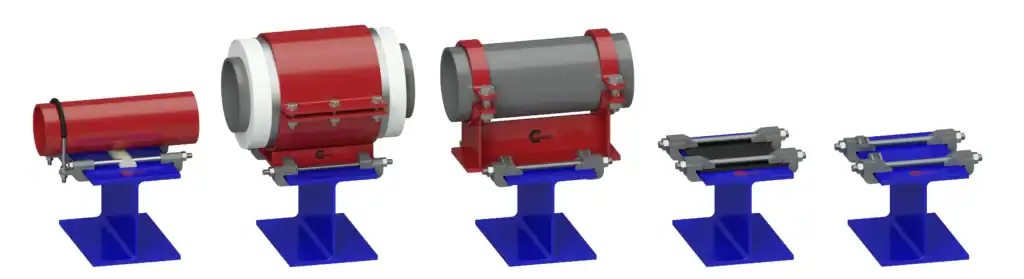

RedLineIPS, under the Cogbill Construction brand, offers a range of non-welded pipe support solutions designed to meet the needs of hazardous environments:

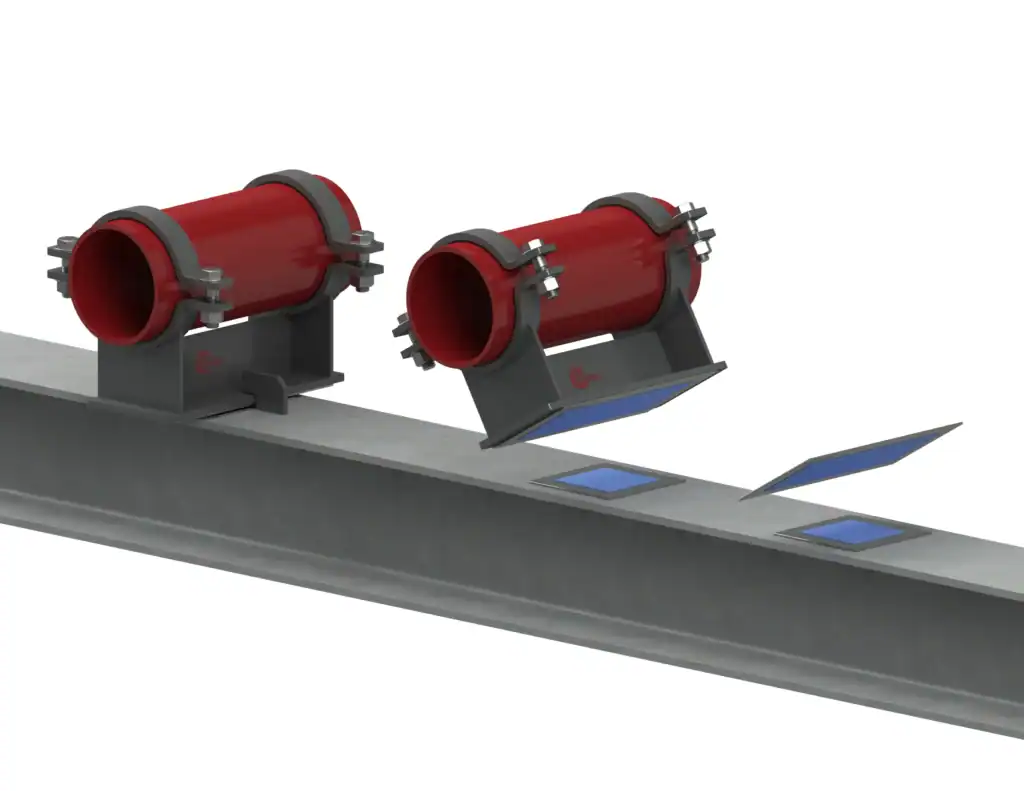

- Adjustable Pipe Saddle Supports: RedLineIPS provides adjustable pipe supports that allow for precise positioning and alignment without the need for welding. They allow pipe attachment without welding through their clamping mechanisms using clamps or U-Bolts. These supports are ideal for systems that require frequent adjustments or are subject to thermal expansion and contraction.

- Hold-Down Clamps: RedLineIPS offers hold-down clamps that provide secure attachment points for large-diameter pipes without the need for welding. These clamps are available with vibration-dampening materials to reduce the impact of dynamic loads.

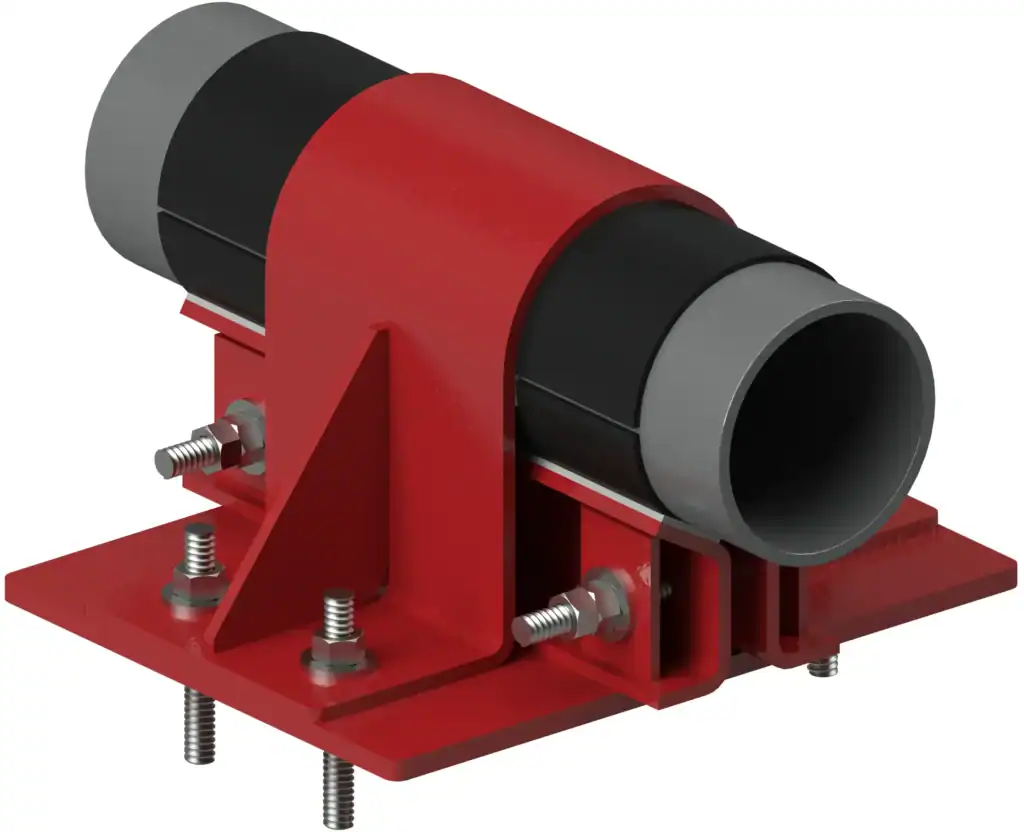

- Shim Block Assembly: The Shim Block Assembly is a height-adjustable support base designed to provide stable, weldless pipe elevation and alignment. Used alone or paired with a hold-down clamp, it can be fitted with low-friction liners to permit axial pipe movement, making it ideal for thermal expansion conditions, while the clamping mechanism secures the pipe in place without welding. The system helps prevent coating damage and corrosion by eliminating metal-to-metal contact, while allowing on-site adjustment and precise load support.

- Clambrace: Clambrace is a structural clamping system that allows pipe supports to be mounted onto existing steel beams without welding, drilling, or epoxy. Its no-weld installation reduces structural risk and eliminates the need for hot work permits. Once secured, Clambrace can accommodate clamp-on pipe shoes and other non-welded pipe support assemblies, making it a fast and modular foundation for fully weld-less support solutions in industrial environments.

- Composite Pipe Supports: For environments where corrosion is a concern, RedLineIPS provides composite pipe supports that are lightweight, durable, and resistant to chemical attack. These supports are ideal for applications in chemical plants, water treatment facilities, and other corrosive environments.

Design Considerations for Non-Welded Pipe Supports

When designing a piping system using non-welded supports, several factors must be considered to ensure optimal performance:

- Load Capacity: Ensure that the selected supports can handle the expected load, including the weight of the pipe, the fluid it contains, and any additional forces due to thermal expansion or vibration.

- Material Compatibility: Choose materials that are compatible with the environment and the fluid being transported. For example, use corrosion-resistant materials such as stainless steel or composites in corrosive environments.

- Flexibility and Adjustability: Select supports that provide the necessary flexibility and adjustability for the specific application. Adjustable supports are ideal for systems that require frequent realignment or are subject to thermal expansion.

- Vibration and Dynamic Load Management: In systems subject to vibration or dynamic loads, use supports with vibration-dampening materials to reduce the impact on the piping system.

Installation and Maintenance Best Practices

Proper installation and maintenance are essential for the effective performance of non-welded pipe supports, as follows:

- Installation Guidelines: Alignment: Ensure that supports are properly aligned to prevent uneven wear and stress on the pipe.

- Secure Attachment: Use the appropriate clamps or fasteners to secure the supports to the structure without over-tightening, which could damage the pipe or support.

- Maintenance Tips:

- Regular Inspection: Periodically inspect supports for signs of wear, corrosion, or damage, especially in high-stress environments.

- Lubrication: Some non-welded supports, such as those with slide plates, may require periodic lubrication to maintain low friction.

- Replacement: Replace any damaged or worn supports promptly to prevent further stress on the piping system.

Non-welded pipe supports offer a safer, more flexible, and efficient solution for securing piping systems in hazardous environments. By eliminating the need for on-site welding, these supports reduce safety risks, installation time, and maintenance costs, making them an ideal choice for industries such as oil and gas, chemical processing, and pharmaceutical manufacturing. RedLineIPS, a brand of Cogbill Construction, provides a range of non-welded support solutions designed to meet the unique challenges of these environments, ensuring the safety, reliability, and longevity of your piping systems.

For more information on the non-welded support solutions, visit our website at RedLineIPS.com to explore the full range of metallic and non-metallic pipe support solutions. Or, contact us at Info@RedLineIPS.com.