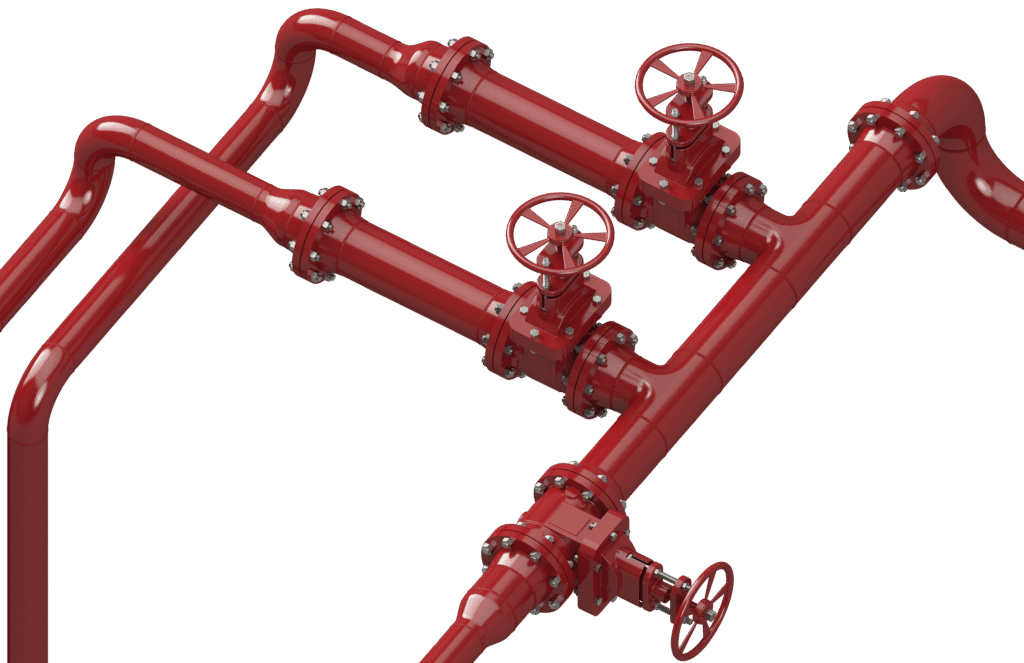

Pipe reducers are a critical element in many industrial piping systems. Their role in managing flow, pressure, and the connection between different pipe sizes is indispensable across a range of industries, including petrochemical, oil and gas, power generation, and more. Pipe reducers are not just mechanical components; they serve essential functions in maintaining fluid dynamics and ensuring operational efficiency in complex piping networks.

This article will delve into the technical aspects of pipe reducers, exploring how they work, why they are important, and how they are manufactured. Additionally, we will discuss how RedLineIPS, through its fabrication shop at Cogbill Construction, supplies both forged and cold-formed reducers to meet a variety of industrial needs.

What Are Pipe Reducers?

A reducer is a pipe fitting used to connect pipes of different diameters. This change in diameter allows the system to transition between various flow rates and pressures while maintaining a smooth flow of the medium—whether it be a liquid, gas, or slurry. Pipe reducers are used extensively in piping systems where maintaining steady flow conditions is critical to the performance of the entire system.

Reducers play a vital role in:

- Flow Management: Controlling fluid velocity and pressure by altering the diameter of the pipe.

- Turbulence Reduction: Minimizing disturbances that could lead to inefficiencies or equipment damage.

- System Integration: Enabling the connection of pipes with different diameters, often necessary during retrofits or system upgrades.

Types of Pipe Reducers

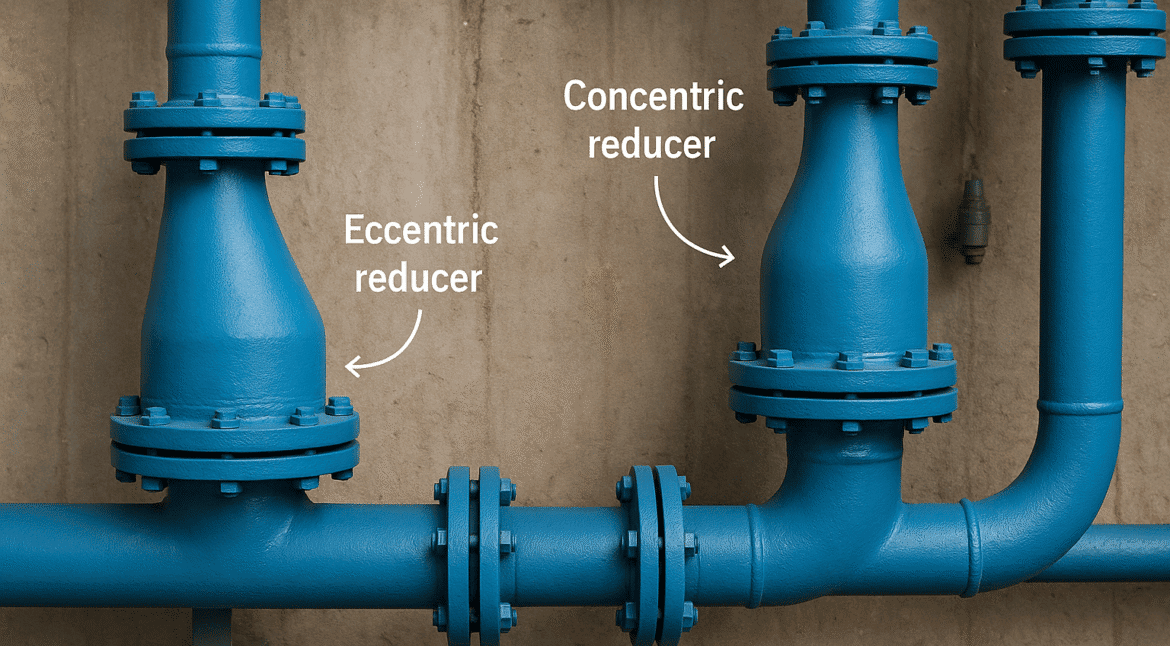

There are two primary types of pipe reducers, each designed for specific use cases:

- Concentric Reducers:

- Description: Conical in shape with the centerlines of the pipes remaining aligned.

- Application: Used in vertical piping systems or where uniform flow is necessary. Often deployed in slurry and liquid transfer lines

- Technical Advantage: By maintaining alignment, concentric reducers ensure uniform pressure distribution and flow transition. This design is particularly useful where uninterrupted fluid flow is critical to prevent cavitation or vibration.

- Eccentric Reducers:

- Description: Offset, with one side of the reducer flat while the other side is sloped.

- Application: Common in horizontal pipelines, especially where liquids are involved. The flat side ensures that no air pockets form within the pipe, which could otherwise lead to pressure spikes or vapor locks.

- Technical Advantage: Eccentric reducers are excellent for systems where the accumulation of fluids, gases, or vapor could compromise safety or efficiency. The design ensures a constant flow without creating "dead zones" where material could pool.

Why Use Pipe Reducers?

From a technical standpoint, reducers are crucial for a number of reasons:

- Flow Control and Management:

- The ability to transition between different pipe diameters is often required to manage flow rates in complex piping systems. By adjusting the diameter, you can control the velocity of the fluid, which in turn impacts the overall system pressure.

- Example: In oil and gas pipelines, maintaining a specific flow velocity ensures that abrasive materials (like sand in oil) don’t cause wear and tear inside the pipes.

- Pressure Optimization:

- As fluid or gas moves through a piping system, changes in pipe diameter naturally affect pressure. A well-designed reducer helps balance these pressure changes, ensuring that the system operates within safe limits.

- Technical Reason: Reducing pipe diameter leads to an increase in velocity, which can drop pressure according to Bernoulli's principle. Properly selected reducers allow engineers to manage this pressure drop without causing system inefficiencies.

- Cavitation Prevention:

- In liquid-carrying pipelines, abrupt transitions in pipe diameter can lead to cavitation—a phenomenon where bubbles form and collapse, potentially damaging the system. Eccentric reducers, with their flat side, help eliminate this risk by maintaining constant flow at the bottom of the pipe.

- Integration of Multiple Systems:

- Industrial plants often expand or modify existing piping systems. When connecting new pipes to older infrastructure, pipe diameters often don’t match. Pipe reducers ensure a smooth, secure connection between pipes of different sizes, without sacrificing flow characteristics or safety.

Manufacturing Processes for Pipe Reducers

The method of manufacturing pipe reducers depends on the material, size, and application. There are three primary ways that reducers are manufactured:

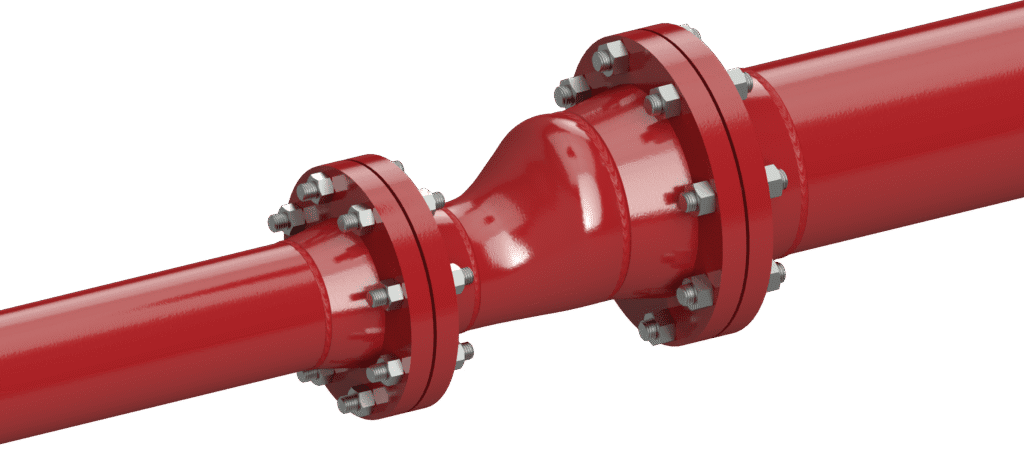

- Cold-Formed from Plate or Sheet Metal:

- Process: Cold-forming involves bending and shaping a flat sheet or plate of metal (usually stainless steel, carbon steel, or FRP) into the desired reducer shape without heating. This process is generally used for reducers with larger diameters or in situations where precise dimensions are required.

- Applications: Cold-formed reducers are typically used in lower-pressure systems or when fabricating custom pieces for specific industrial needs. Plate-formed reducers are also common in environments where lightweight materials like FRP (Fiber Reinforced Plastic) are preferred due to their corrosion resistance.

- Capabilities: At Cogbill Construction’s sheet metal shop, RedLineIPS can manufacture reducers from sheet metal and plate, offering custom solutions for both standard and complex requirements.

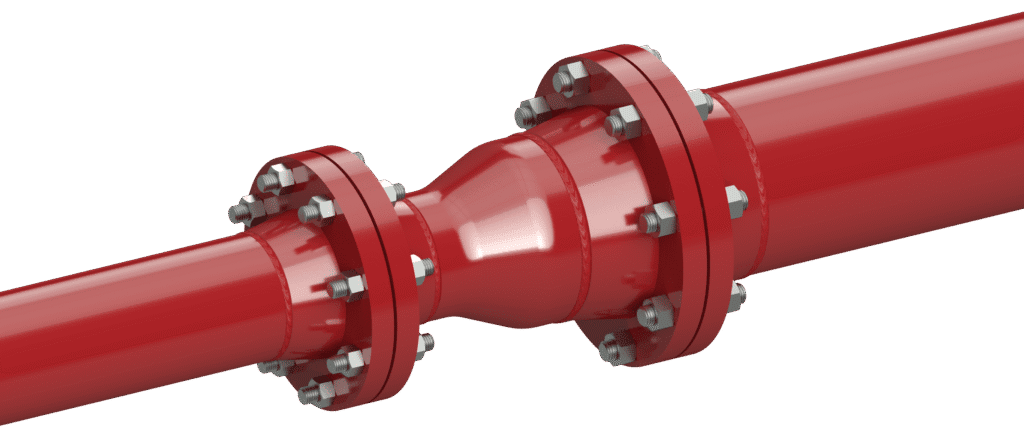

- Forging:

- Process: The reducer is shaped by compressing and molding metal under high pressure and heat.

- Applications: Forged reducers are often used in high-pressure systems, such as those found in oil refineries, power plants, and chemical processing plants. The forging process results in reducers that have excellent mechanical properties, such as high strength and durability.

- Materials: Forged reducers are typically made from materials like carbon steel, stainless steel, and alloy steel.

- Supplier: RedLineIPS supplies a full range of forged reducers, offering high-performance solutions for demanding industrial environments.

- Casting:

- Process: Casting involves pouring molten metal into a mold shaped like the desired reducer. The metal solidifies into the reducer’s form as it cools. After solidification, the mold is removed, and the reducer undergoes finishing processes like trimming and surface treatment to meet design specifications.

- Applications: Cast reducers are particularly useful for large, complex, or non-standard designs where other methods, such as forging or cold-forming, may be impractical or cost-prohibitive. They are commonly used in low-pressure systems, large-diameter piping, and situations requiring intricate shapes or special customization.

- Advantages: Casting allows for the economical production of reducers with detailed or unique geometries. It is particularly beneficial for large-scale projects where precision and consistency are crucial. Cast reducers can be made from a wide range of materials, including carbon steel, stainless steel, and alloys, to suit diverse environmental and operational requirements.

- Supplier: RedLineIPS supplies high-quality cast reducers that are available for specialized and industrial needs, combining durability with tailored designs for optimal performance.

Materials of Construction

The material from which a reducer is made is as crucial as its design. Each material has its own technical advantages, and the selection of material must align with the operating environment, fluid or gas type, and mechanical requirements.

- Carbon Steel:

- Characteristics: High strength, cost-effective, excellent for high-pressure applications.

- Applications: Commonly used in petrochemical plants, refineries, and power generation systems. It handles high-pressure fluid transfer efficiently.

- Stainless Steel:

- Characteristics: Superior corrosion resistance, good mechanical properties at high temperatures.

- Applications: Stainless steel reducers are typically used in chemical plants, food processing industries, and in corrosive environments where hygiene and resistance to aggressive chemicals are critical.

- Alloy Steel:

- Characteristics: Enhanced strength and heat resistance due to the alloying elements.

- Applications: Used in extreme environments such as high-temperature steam lines or in chemical processes involving corrosive media.

- FRP (Fiber Reinforced Plastic):

- Characteristics: Lightweight, corrosion-resistant, ideal for non-metallic piping systems.

- Applications: FRP reducers are commonly used in environments where metallic materials would degrade quickly, such as wastewater treatment plants and chemical processing units dealing with highly corrosive substances.

Technical Considerations in Using Pipe Reducers

The decision to use a pipe reducer and the type of reducer required depends on various technical factors. These include:

- Flow Velocity: A reducer helps regulate flow velocity, which is important for minimizing wear and tear in piping systems. Abrupt changes in flow velocity can lead to erosion, cavitation, or pressure surges, all of which reduce system efficiency and lifespan.

- Pressure Loss: When changing pipe sizes, a slight pressure drop is inevitable. However, a properly designed reducer minimizes turbulence, ensuring that the pressure loss does not negatively impact the overall system performance.

- Vibration Control: In piping systems where fluids or gases flow at high speeds, vibration can occur. Reducers, particularly eccentric ones, help manage these vibrations, preventing damage to both the pipes and the associated machinery.

In short, pipe reducers are a vital component in the design and operation of industrial piping systems. Their ability to manage flow, optimize pressure, and integrate different sections of piping makes them indispensable in numerous industries, from petrochemical plants to power generation facilities.

Whether cast, forged or cold-formed from plate, the choice of reducer design and material directly impacts the performance and reliability of the entire system. At RedLineIPS, we offer a full range of reducers—both forged and custom-manufactured from sheet metal or plate. Our expertise ensures that you receive the right reducer for your specific application, maintaining system efficiency, safety, and longevity.

For more information on our high-quality pipe fittings and reducers, visit our metallic pipe fittings page.