Offshore piping tends to fail where it is hardest to see: the narrow strip of contact where a pipe rests on its support. In that shaded gap, salt spray, washdowns, condensation, and constant micro-movement keep moisture in place and bruise coatings. Over time, this creates Corrosion Under Pipe Supports (CUPS), raises structure-borne noise and vibration, adversely impacts pipe and support structural integrity, and in the worst cases leads to small leaks that can escalate into fires or explosions.

This article explains what offshore platforms and FPSOs are (and why their environments stress pipe supports), expands on the main CUPS mechanisms, and then shows how the RedLineIPS SmartPad System, by Cogbill Construction, mitigates corrosion, vibration/sound, and long-term structural risks. We will close with practical benefits—fast, cold installation, easy direct inspection, and compatibility with retrofit and new build work.

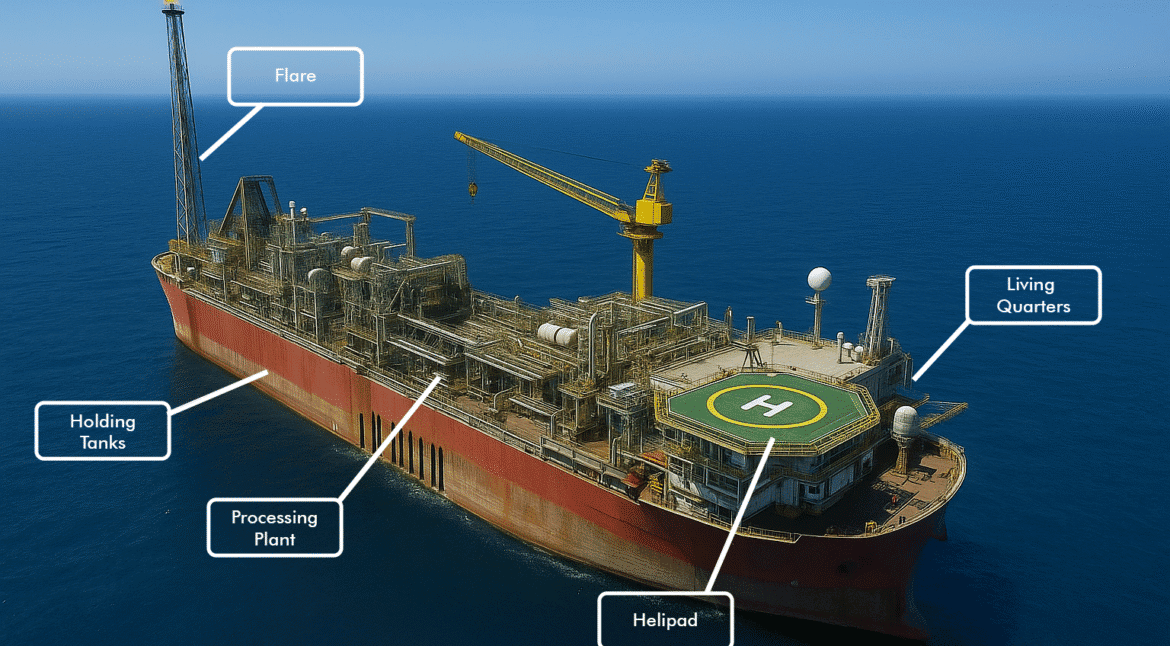

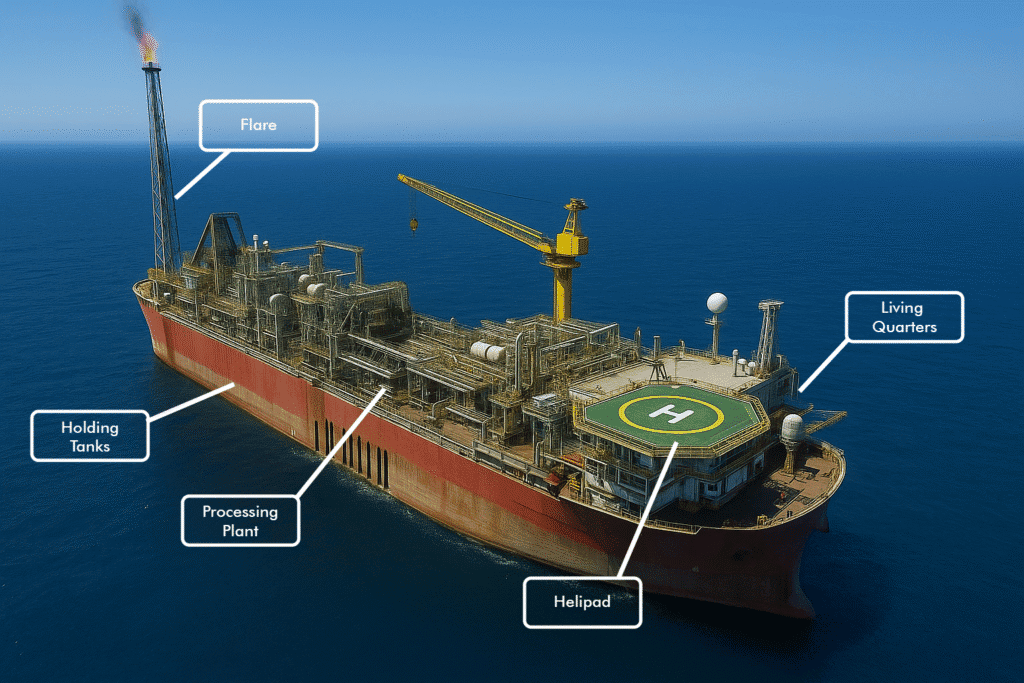

Offshore platforms and FPSOs: operating realities

- Offshore platformsOffshore platforms are stationary structures anchored to the seabed—steel jackets, gravity-based structures, and compliant towers, built to hold production equipment above the ocean. Their topsides concentrate separators, pumps, scrubbers, exchangers, power generation, and utilities into dense pipe racks with thousands of support points. Typical exposure includes:

- Marine atmosphere: wind-driven salt spray, UV, high humidity, and frequent wet-dry cycling from rain and washdowns.

- Firewater and housekeeping: periodic testing and routine cleaning that soak racks and supports.

- Congestion and access limits: closely spaced pipes with limited reach to the underside of support contacts.

- Thermal movement: daily and seasonal temperature swings plus process upsets that make pipes expand/contract over supports.

- FPSOs (Floating Production, Storage and Offloading units)FPSOs are ship-shaped facilities that process hydrocarbons, store stabilized crude in internal tanks, and offload to shuttle tankers. They experience everything a fixed platform does plus constant heave, roll, and pitch, occasional slamming loads, and widespread condensation from temperature gradients across decks and modules. Key attributes that matter for supports:

- Motion: hull dynamics keep tiny interfaces “alive,” encouraging micro-slip at supports and pumping moisture into crevices.

- Layout density: modular plants packed onto a finite deck area; supports are everywhere and often difficult to reach.

- Variable service: chilled lines, ambient lines, and hot services share the same racks, so one support philosophy must work across a broad temperature/chemistry window.

- Inspection constraints: more work at height and in congested spaces, so short, repeatable interventions are far safer and cheaper than long, specialized jobs.

For the discussion that follows, think of an FPSO as a motion-intensified offshore platform with more frequent wetting and more persistent micro-movement at support interfaces.

CUPS: how it forms and why it persists

CUPS is corrosion that initiates and propagates in the pipe/support contact. Electrolyte films linger, oxygen becomes uneven, and even a tiny coating nick can seed a self-sustaining reaction. The main modes work together and accelerate one another, and they include:

-

Crevice corrosion.

In a narrow, stagnant gap the oxygen is quickly consumed. The chemistry shifts acidic and chloride-rich as metal ions hydrolyze. The crevice becomes an anode; under-film attack accelerates from a small defect. Once the crevice “goes active,” even good surrounding coating can’t protect the hidden area.

-

Under-deposit corrosion (UDC).

Salt crystals, silt, rust scale, and organic debris form a “dirt cap” that traps moisture. Different oxygen levels under and around the deposit create differential aeration cells. Pits grow where you can’t see them. On topsides, firewater residue and salt fallout are common deposit sources.

- Microbiologically influenced corrosion (MIC). Biofilms—often sulfate-reducing bacteria—alter local chemistry by producing sulfides and shifting pH. The result is irregular, aggressive pitting. MIC thrives in warm, intermittently wet crevices, exactly like those under supports.

- Chloride pitting (carbon steel).Chlorides exploit tiny coating nicks, initiating deep pits that can reach through-wall before anyone notices. Pitting is common on splash-exposed faces and in areas with frequent wet-dry cycling.

- Galvanic and differential-aeration couples. A metal-to-metal path (pipe on steel support) closes an electrical circuit; the pipe can become the anode and corrode faster at the contact band. Even with identical alloys, oxygen differences between the tight gap and open air create an electrochemical imbalance that drives material loss.

Why it persists: the contact is shaded and tight, so it is hard to dry, clean, coat, or even see. Rigid metal-to-metal interfaces promote micro-slip that rubs coatings and keeps chemistry “active.” If the mitigation creates new crevices (e.g., imperfect epoxy fillets) or leaves metal continuity, the problem returns.

The SmartPad System:

The RedLineIPS SmartPad System, by Cogbill Construction in Texas, replaces steel-on-steel contact at supports with a sealed, dielectric, reopenable interface. It installs cold on live lines—no welding, drilling, or epoxy—and opens quickly so crews can view the hotspot directly, wipe it clean, take photos, and re-seal in minutes. System components are:

- Composite (FRP) SmartPad — contoured saddle. Spreads bearing load (no point/line loading), protects coatings with smooth, radiused contact, and includes recessed grooves that prevent composite bands from “walking” or damaging structural support paint coatings. Sloped edges help the pad recenter after large thermal movement. The FRP is dielectric (mitigates galvanic corrosion) and UV-resistant (resilient in onshore and offshore applications) and is purpose-built for pipe supports (not repurposed FRP piping or ducting).

- Hydroseal gasket — bonded, closed-cell seal and damper. Compresses into the paint texture to form a watertight interface at the pipe/pad contact. Closed-cell construction blocks capillary wicking. The elastomer damps micro-motion, reducing rattle and transmitted vibration. There are no epoxy cure windows and no risk of hidden perimeter voids.

- SmartBand & Buckle — composite clamping with stable preload. All-composite bands and square-tooth, non-backdrivable buckles hold durable preload without metal contact. Bands seat in the pad’s recessed grooves to resist migration. For inspection, bands are cut and replaced—enabling a fast lift–look–re-band visual inspection as opposed to expensive inspection methods such as radiography and ultrasonic testing.

- SmartTool — Applies repeatable band load so gasket compression is consistent across crews and shifts. Integrated tail trimming keeps installs neat. Available in manual, mechanical, and pneumatic versions to match campaign pace.

With those parts in place, the RedLineIPS SmartPad System directly targets the conditions that create CUPS and the mechanical effects that sustain it.

How SmartPads help: corrosion

Seal the crevice, break the circuit, protect the coating, and starve the chemistry—that’s the corrosion playbook. SmartPad executes it at the support locations as follows:

- Sealing the gap: The bonded, closed-cell gasket compresses to form a watertight interface when properly installed, excluding thin brine films, even on windward faces, in washdown paths, and on sweating cold services. Without stagnant electrolyte, crevice corrosion struggles to start and UDC deposits don’t get a foothold.

- Isolating metals:The FRP saddle, elastomer gasket, and composite bands create an all-non-metallic load path between pipe and steel support. That breaks electrical continuity and disrupts galvanic and differential-aeration cells. It also reduces stray current pathways that sometimes complicate CP/earthing strategies.

- Protecting coatings:The contoured saddle distributes bearing loads; smooth, radiused contact avoids the harsh line loading that bruises paint. The band-in-groove layout keeps clamp force on the saddle rather than the coating edge. Fewer coating bruises mean fewer CUPS seeds.

- Discouraging deposits and biofilms:A sealed, smooth interface reduces debris traps. Less trapped salt and organic matter mean fewer UDC sites and poor habitat for MIC biofilms.

- Maintaining the fix over time:The square-tooth buckle resists back-drive under vibration and thermal cycles; the recessed grooves prevent band migration. A stable preload means the gasket stays compressed, the seal stays intact, and the dielectric separation continues to work.

Safety tie-in: fewer through-wall defects at supports lower the probability of leak → ignition scenarios. That directly supports process safety, environmental performance, and regulatory confidence.

How SmartPads help: vibration and sound

Rigid, metal-on-metal supports transmit vibration efficiently into the pipe and structure; any micro-slip grinds coatings and keeps the crevice “alive.” SmartPads replace that with a hard-to-damped contact.

- Damping micro-motion:The elastomer gasket behaves like a tuned cushion or a memory-foam mattress for pipes, absorbing small relative movements from hull dynamics and thermal growth. Lower micro-slip means less fretting, less coating wear, and fewer opportunities for corrosion to start.

- Reducing structure-borne noise:By decoupling the metal path and inserting a viscoelastic layer, SmartPad cuts the efficiency with which vibration becomes audible noise at the support. On busy decks, this can make a perceptible difference in rattles during sea-state changes and help teams meet acoustic comfort and exposure targets.

- Holding preload under cycling:Durable band tension (non-backdrivable buckle) and the anti-walk grooves preserve compression across cycles. Stable compression preserves damping performance and keeps the interface sealed.

Practical payoffs: quieter racks, fewer fastener-loosening events, and fewer vibration-related coating failures that become corrosion hotspots later.

How SmartPads help: structural integrity over time

Integrity is a long game. Reducing corrosion and damping motion both feed into longer life for pipes as well as their supporting structures, in the following manner:

- Lower fatigue initiation:With coatings protected and micro-motion damped, there are fewer stress raisers and less fretting at supports, the classic seeds of fatigue cracks. Supports no longer act as sandpaper on the pipe.

- Reduced local stress:Spreading the contact over a contoured saddle lowers bearing stress peaks compared to narrow or point/line contacts. Lower peak stress improves margins in areas where wall thickness is already at a premium.

- Easier, better inspections:Because the interface opens in minutes, teams can verify the hotspot directly rather than relying only on indirect NDT or waiting for scaffolds and permits. Direct visuals, wipe-downs, and photos allow earlier intervention if something starts to go wrong.

While fatigue life depends on design and loads, a sealed, dielectric, damped interface is the favorable baseline for long-term structural health.

Other benefits that matter offshore

- Cold work on live lines:Installation requires no hot work—no welding, grinding, drilling, or epoxy. That simplifies permits, avoids cure windows and solvent handling, and reduces ignition and VOC (volatile organic compound) exposure. On an FPSO or crowded offshore platform, those are high-value wins.

- Rapid “lift–look–re-band” inspections:For inspection, crews cut bands, lift the pad, wipe and photograph the surface, then fit new bands and re-seal—often in minutes per support. Inspection duration can be reduced while exposure hours at height are trimmed. Teams rely less on expensive indirect NDT when a quick direct visual will answer the question.

- Retrofit-friendly and newbuild-ready:The conformal, closed-cell gasket accommodates minor surface irregularities common in brownfield work, avoiding grinding to perfectly flat steel or waiting on epoxy cures. For newbuilds, specifying the sealed, dielectric interface in support standards and isometrics prevents early-life crevice/galvanic drivers and first-year rework.

- Materials assurance and compatibility:The RedLineIPS SmartPad System uses proven building blocks: industrial FRP laminates, closed-cell structure elastomers, and composite banding, all long-established offshore. Gasket chemistries (e.g., EPDM, silicone, PTFE-faced) can be matched to media and temperature. The all-non-metallic load path plays well with cathodic protection/earthing; isolation can be confirmed with a simple resistance check after installation.

- Practical TCO levers:Minutes per support instead of hours for welded/epoxied options; broader crew utilization (no coded welders or adhesive specialists for the interface); less coating rework (no spatter, drilling, or adhesive cleanup); reusable hardware (re-use the saddle and buckles; replace low-cost band stock); fewer emergency repairs because detection is earlier and corrosion is slower to start. These advantages apply to both fixed platforms and FPSOs, with the savings often more visible on motion-rich floating assets.

Putting it all together

Whether your asset is fixed or floating, the same fundamentals apply at pipe supports: moisture wants to sit in the crevice, galvanic paths want to close, and motion wants to keep the chemistry active. The RedLineIPS SmartPad System addresses those fundamentals in one practical package:

- Seal the gap so water can’t sit in it.

- Isolate the metals so galvanic cells can’t run.

- Spread the load so coatings don’t bruise into failure.

- Damp the motion so fretting and noise don’t build.

- Open it quickly so you can see the hotspot and re-seal without drama.

When those five conditions are true, CUPS becomes far less likely, vibration becomes less harmful, and inspections become faster, safer, and more definitive.

Conclusion

CUPS, vibration, and fatigue at pipe supports are predictable problems on offshore platforms and FPSOs—but they are also preventable with the right interface. By replacing steel-on-steel contact with a sealed, dielectric, and reopenable system, the RedLineIPS SmartPad cuts off the corrosion pathway, reduces structure-borne noise and micro-motion, and turns inspections into a quick, direct routine.

For newbuilds, SmartPad sets the contact up correctly from day one. For brownfield assets, it delivers quick wins where risk is highest and access is tight. In both cases, it supports better integrity outcomes, leaner maintenance, and a clearer safety story, without hot work, adhesives, or long downtime. If your topsides spend too much time chasing touch-ups, rattle, and hidden corrosion at supports, SmartPad is a straightforward change with outsized impact.