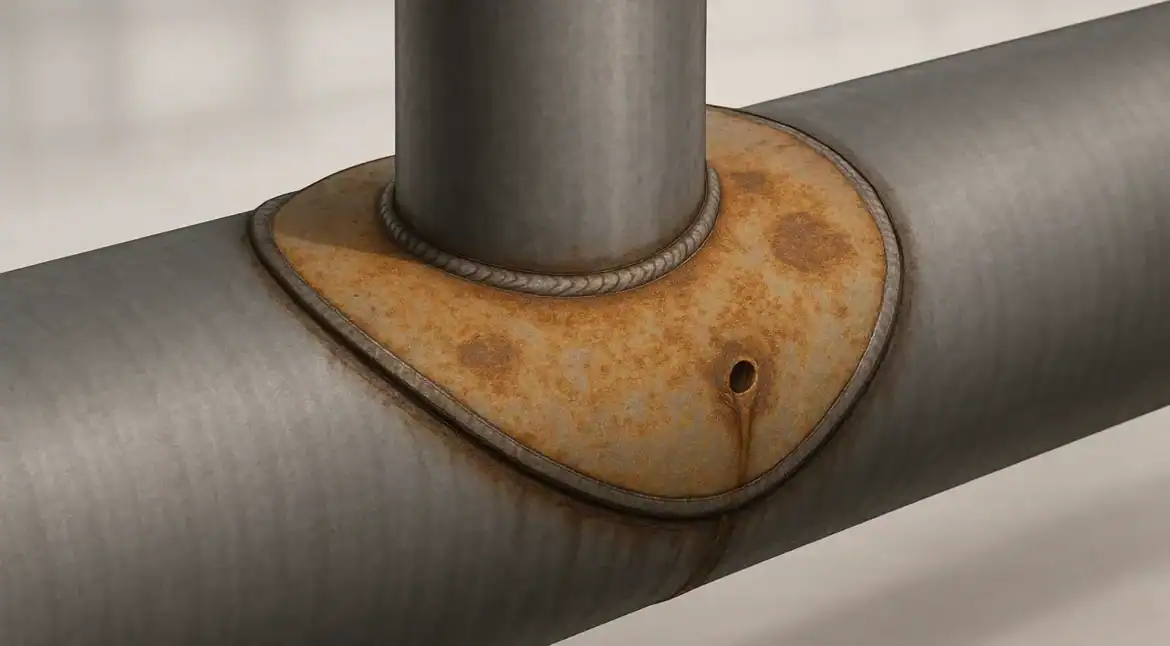

Reinforcement pads (“repads”) are installed to make branch connections and nozzles stronger—but in the real world they often become some of the worst corrosion hot spots on the line. Tight crevices, difficult coating transitions, wet insulation, and galvanic couples can turn a repad into a prime location for CUI and…

The evolution of reinforcement pad (Repad) design has significantly advanced industrial piping systems. Originally basic metal reinforcements, Repads now feature custom designs and high-performance materials like composite materials and advanced alloys for enhanced strength, corrosion resistance, and adaptability in various environments. With the integration of technologies such as Finite Element…