In industrial settings, particularly in industries like oil and gas, chemical processing, and power generation, pipe supports play a crucial role in maintaining the integrity, safety, and efficiency of piping systems. A vital yet often underappreciated component in many pipe supports is the isolation liner, which protects the pipes from external forces, corrosion, and wear, while it may dampen vibration and noise. Among the most effective materials used for these isolation liners is Cotton Duck Pads. These pads have proven to be highly effective in mitigating vibration, corrosion, and noise, while offering durability in harsh environments.

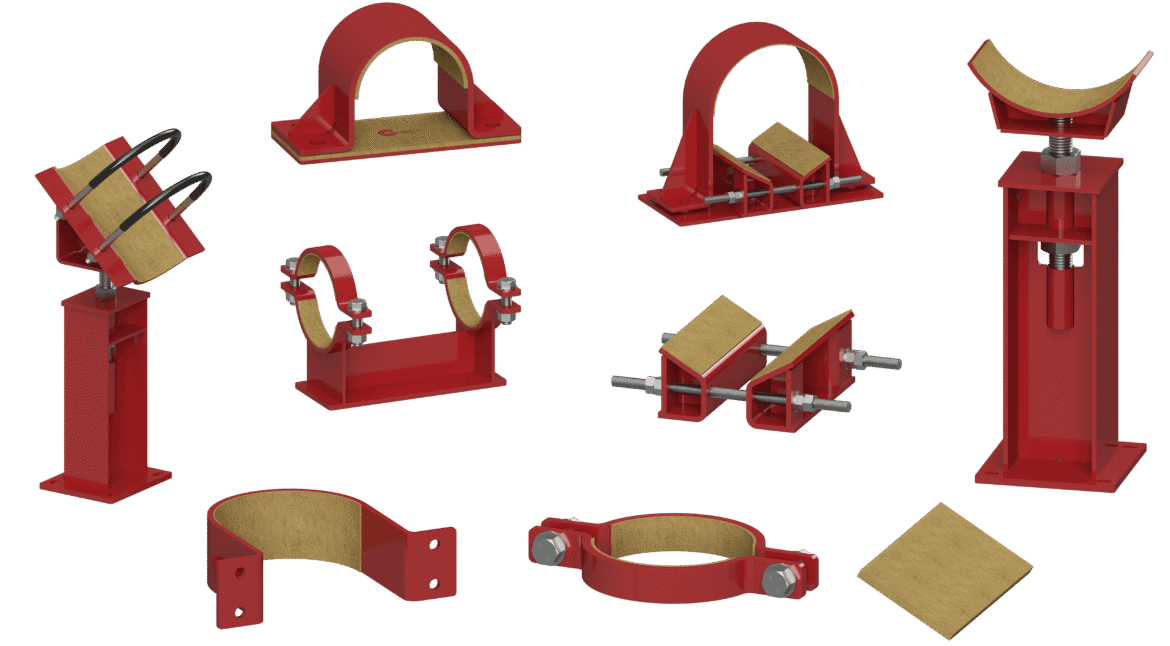

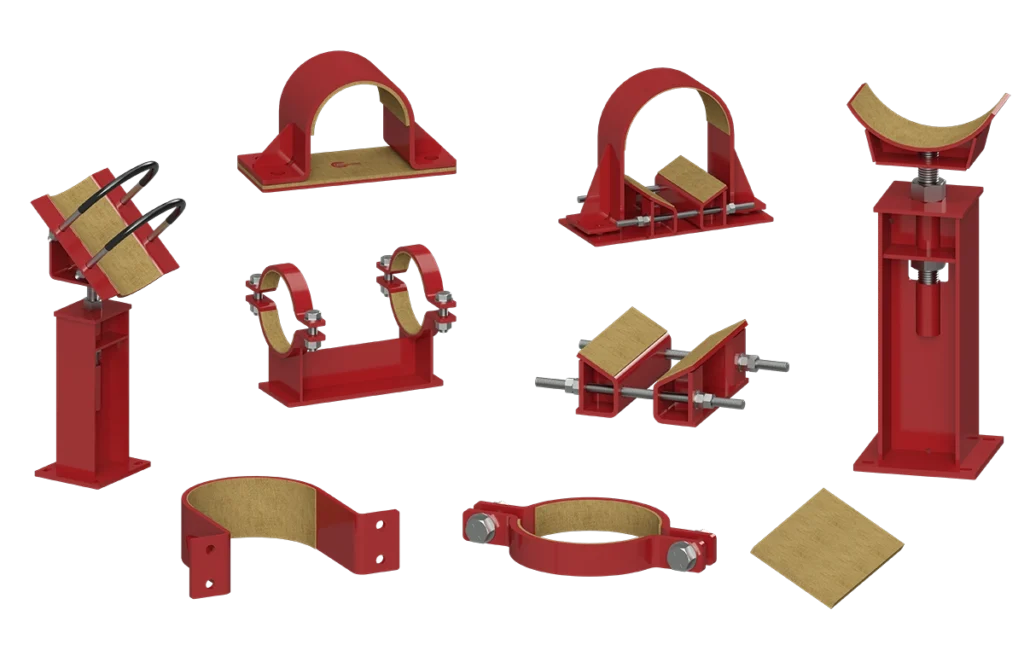

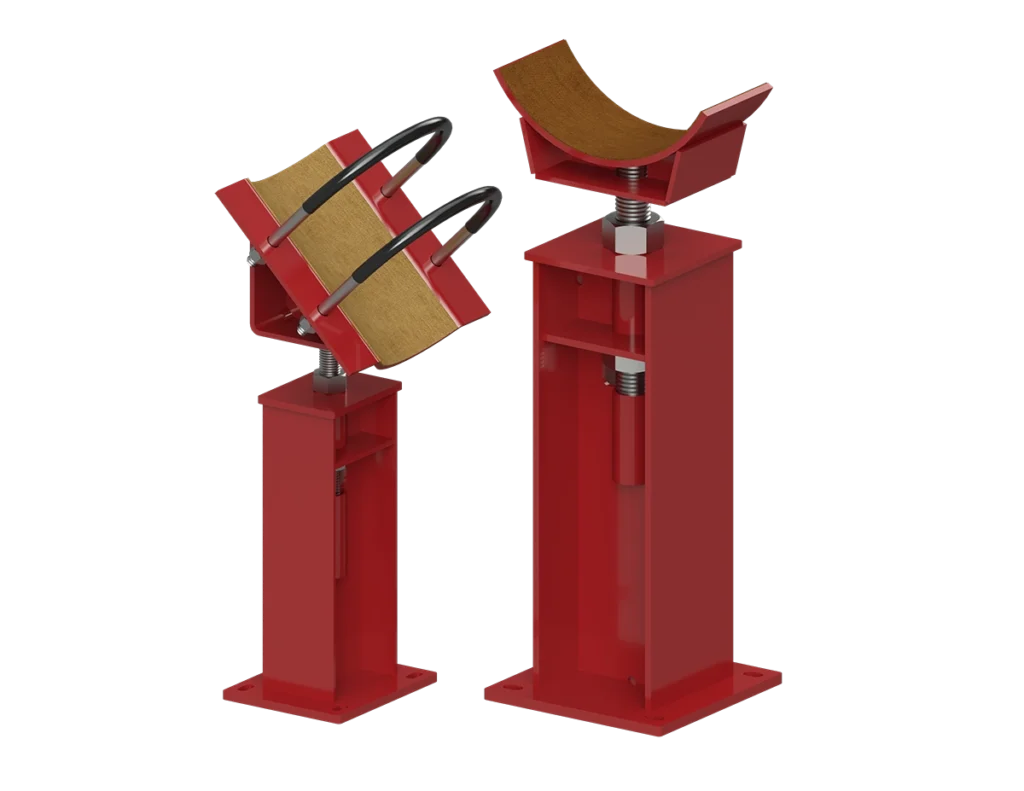

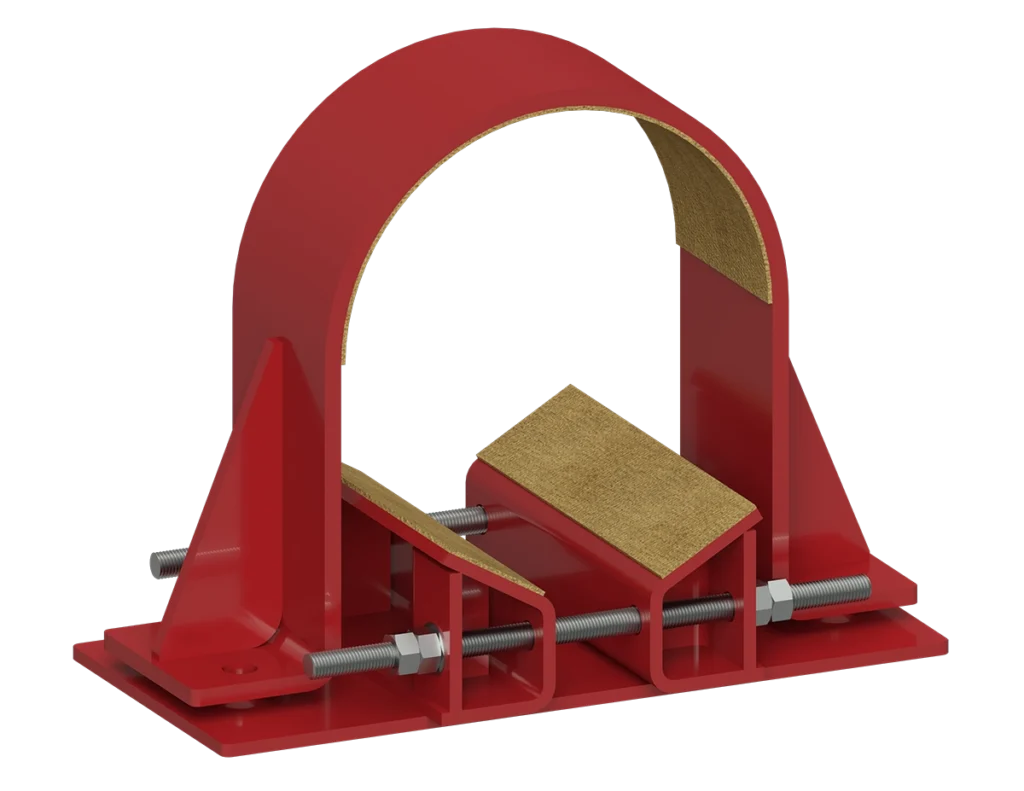

At Cogbill Construction, through our RedLineIPS brand of heavy-duty piping products, we manufacture and provide a range of metallic supports integrated with Cotton Duck Pads. In this article, we explore the technical properties, applications, and installation considerations for Cotton Duck Pads in industrial pipe supports such as pipe shoes, adjustable and non-adjustable supports, pipe clamps, hold-down clamps with Shim Block Assemblies, and pipe hangers. We will also discuss installation methods, including the use of adhesives and tapes like the double-sided 3M VHB tape, to secure these pads in place.

What Are Cotton Duck Pads?

Cotton Duck Pads are made from a heavy-duty plain-woven cotton fabric that is typically impregnated with rubber or other elastomers to enhance its durability and resistance to harsh industrial environments. The fabric’s tight weave provides high strength, abrasion resistance, and flexibility, which are all key characteristics needed for use in pipe support systems.

Composition and Properties

- Base Fabric: Tightly woven cotton, providing excellent tensile strength and flexibility.

- Impregnation: Rubber or elastomer impregnation to improve moisture resistance, chemical resistance, and durability.

- Physical Characteristics: Cotton Duck Pads are available in varying thicknesses (typically between 1/8” to 1/2"), offering customizable solutions based on load-bearing and vibration-dampening needs.

This unique material is widely used as an isolation liner in industrial pipe supports, offering several technical advantages. Learn more about the variety of pipe supports at RedLineIPS.

Key Technical Properties of Cotton Duck Pads

Physical Properties

- Thickness: Cotton Duck Pads are offered in thicknesses ranging from 1/8 inch to 1/2 inch, tailored to meet specific industrial requirements, such as load distribution and vibration dampening.

- Flexibility: One of the most significant properties of Cotton Duck Pads is their flexibility. The pads can easily conform to the shape of pipe shoes, pipe clamps, and hangers, making them ideal for curved surfaces such as saddles and complex configurations in both adjustable and non-adjustable pipe supports.

Mechanical Properties

- Tensile Strength: The woven cotton provides excellent tensile strength, which allows the material to resist tearing, even in high-load applications. This makes Cotton Duck Pads suitable for use in environments where the pipe supports are subjected to significant stress and vibration.

- Durability: The rubber-impregnated fabric is designed to withstand heavy-duty applications and resist degradation caused by continuous use or environmental exposure, including corrosion and chemical exposure.

Corrosion Resistance

One of the primary reasons Cotton Duck Pads are used in pipe supports is their ability to mitigate galvanic corrosion. When metal pipes are in contact with metal supports, corrosion often occurs at the points of contact. Cotton Duck Pads provide a non-conductive barrier between the pipe and support, preventing direct metal-to-metal contact, thus reducing the risk of Corrosion Under Pipe Supports (CUPS). This is particularly important in offshore and marine environments, where exposure to saltwater and moisture is constant.

Vibration Dampening and Noise Reduction

Vibration Control:

Cotton Duck Pads exhibit exceptional vibration-dampening performance due to their composite structure of woven cotton fabric saturated with rubber compounds—typically neoprene or nitrile. The fabric weave provides multidirectional mechanical resilience, while the elastomer matrix offers viscoelastic damping. When dynamic forces from rotating equipment, pumps, or turbulent flow act on the piping system, the Cotton Duck Pad compresses slightly and absorbs part of the vibrational energy. This energy is then dissipated as low-level heat within the rubber matrix, significantly reducing the transmission of vibration from the pipe to the support structure. These pads are especially beneficial in applications with cyclic or harmonic loading, such as in power generation plants, refineries, and chemical process units.

Noise Reduction:

Because mechanical vibration is a primary source of structure-borne noise in piping systems, controlling vibration leads directly to measurable reductions in acoustic emissions. Cotton Duck Pads act as isolators, interrupting the vibrational transmission path between the pipe and its support beam. This dampens high-frequency vibration modes associated with flow-induced turbulence or mechanical resonance. While specific decibel (dB) reduction values vary by system geometry and frequency, field use has shown noticeable decreases in ambient noise, contributing to safer and more comfortable work environments. Moreover, their ability to prevent metal-to-metal contact further reduces the risk of impulse noise events, such as those caused by thermal expansion shocks or transient load shifts.

Installation Considerations

One of the key advantages of Cotton Duck Pads is their flexibility in installation. They can be cut, shaped, and secured to fit many pipe support configurations, whether it is pipe shoes, pipe clamps, hangers, etc.

- Bending and Shaping: Thanks to the flexibility of the material, Cotton Duck Pads can easily be bent or shaped around curved surfaces. This makes them ideal for pipe supports that require the material to conform to the surface of pipes, especially in pipe shoes, clamps, and saddle supports. However, it is essential to note that while the pads can be shaped for mild curves, they are not intended for tight or sharp bends, as they are fabric-based and not as malleable as metal.

- Adhesive Methods for Securing Cotton Duck Pads: Cotton Duck Pads can be installed using industrial adhesives or tapes. Depending on the application and the environmental conditions, different methods can be applied:

- Industrial Adhesives: Rubber-based adhesives are commonly used to secure Cotton Duck Pads to metallic pipe supports. These adhesives offer excellent bonding strength and can withstand high temperatures and exposure to chemicals. Epoxy-based adhesives are also an option when a more permanent and heat-resistant solution is needed.

- 3M VHB Tape: For lighter-duty applications or where temporary installation is required, 3M VHB (Very High Bond) double-sided tape can be used to secure the Cotton Duck Pads. This tape offers high shear strength and can withstand vibrations, moisture, and heat. However, for high-load applications, more robust adhesives or mechanical fastening methods may be preferable.

- Considerations During Installation

- Surface Preparation: Before installing Cotton Duck Pads with adhesives, ensure that the surface is clean, dry, and free from oils or debris. Proper surface preparation is crucial to achieving a strong bond.

- Temperature and Environmental Conditions: Ensure the selected adhesive or tape is rated for the environmental conditions of the installation, such as temperature extremes or chemical exposure.

Applications of Cotton Duck Pads in RedLineIPS Pipe Supports

At RedLineIPS, we integrate Cotton Duck Pads, as well as other isolation liners we supply, into a wide variety of pipe support systems. Below are the key types of pipe supports that benefit from the use of Cotton Duck Pads:

- Pipe Shoes: Cotton Duck Pads are commonly used in pipe shoes to prevent direct metal-to-metal contact, mitigating the risk of corrosion. The pads also allow for a small degree of thermal expansion and contraction, making them ideal for high-temperature applications. To learn more, visit our pipe shoes page.

- Adjustable and Non-Adjustable Pipe Supports: Cotton Duck Pads are integrated into both adjustable and non-adjustable pipe supports to reduce vibration, distribute loads, and protect against wear. Adjustable supports allow for fine-tuning the alignment, and the pads help in reducing friction as pipes expand and contract during operation. Explore more about our adjustable and non-adjustable pipe supports.

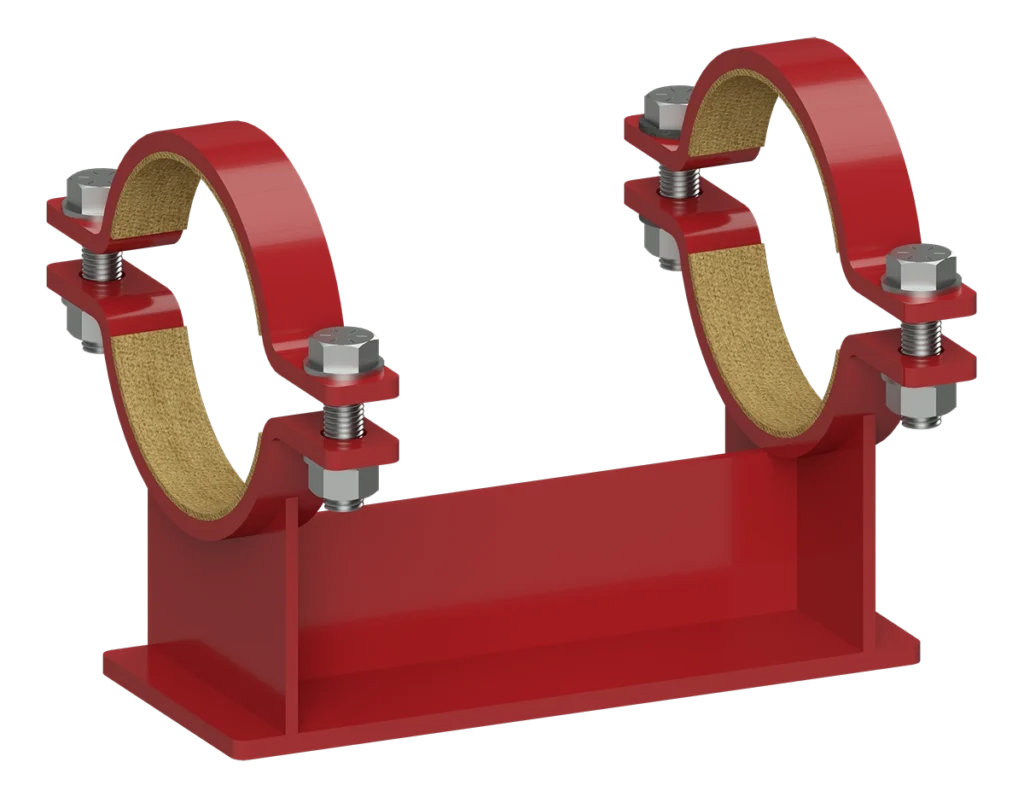

- Pipe Clamps and Hangers : In pipe clamps and hangers, Cotton Duck Pads act as vibration isolators, preventing the transfer of mechanical vibrations from the pipes to the structure. This is particularly valuable in systems where excessive vibration could lead to material fatigue or noise issues. For more information on our pipe clamps, visit our pipe clamps and pipe hangers pages.

- Shim Block Assemblies: Shim block assemblies play a crucial role in providing precise alignment and elevation adjustments in industrial piping systems. When combined with Cotton Duck Pads, shim block assemblies offer enhanced protection against vibration and corrosion, especially in applications where pipes must be carefully aligned or supported on uneven surfaces. The Cotton Duck Pads act as protective liners between the pipe and the shim block, reducing the risk of wear and corrosion by distributing the load evenly and isolating the pipe from metal surfaces.

Why Choose RedLineIPS?

As a trusted brand by Cogbill Construction, RedLineIPS offers a wide range of pipe support solutions designed to meet the demanding needs of industrial environments. From pipe shoes to clamps and adjustable supports, our products are manufactured to the highest standards of durability, safety, and performance. Cotton Duck Pads, and other isolating liners, are integral to these systems, providing a key component in ensuring the long-term reliability of your piping infrastructure.

Explore Cogbill Construction’s expertise in metal fabrication by visiting their metal fabrication pages and discover how we can support your next project with high-quality, custom solutions.