Pipe supports play a vital role in the operation, safety, efficiency, and longevity of piping systems in petrochemical and gas facilities. These systems are crucial for transporting a myriad of substances, including oil, natural gas, and various chemical products, under conditions that may involve high pressures and temperatures, mechanical stress, and environmental challenges.

Importance of Pipe Supports

The primary function of pipe supports is to anchor, guide, support, and absorb shock, ensuring the structural integrity and reliable operation of pipeline systems. In petrochemical and gas plants, where safety and efficiency are paramount, the correct installation and maintenance of pipe supports directly impact operational effectiveness.

Types of Pipe Supports

- Primary Pipe Supports: These are essential for the safe transport of fluids and gases, helping to prevent pipe sagging, bending, and excessive movement which could lead to structural failures.

- Secondary Pipe Supports: These supports maintain alignment and prevent undue stress on pipelines, thereby preserving the integrity of the system.

- Insulated Pipe Supports: These are used to control heat loss or gain in the system, providing both structural support and thermal insulation.

Examples of Pipe Supports

- Adjustable Pipe Supports: These supports usually cater to pipes ranging from 1/2" to 72", featuring options for non-metallic liners to prevent metal-to-metal contact, crucial for managing corrosion and vibrations. They are designed for easy installation and height adjustments.

- Non-Adjustable Pipe Supports: These economic options offer stable supports but without the advantage of height adjustability. Examples include stanchions, dummy legs, and trunnions, usually made from diverse materials, with the aim of enhancing system safety and durability.

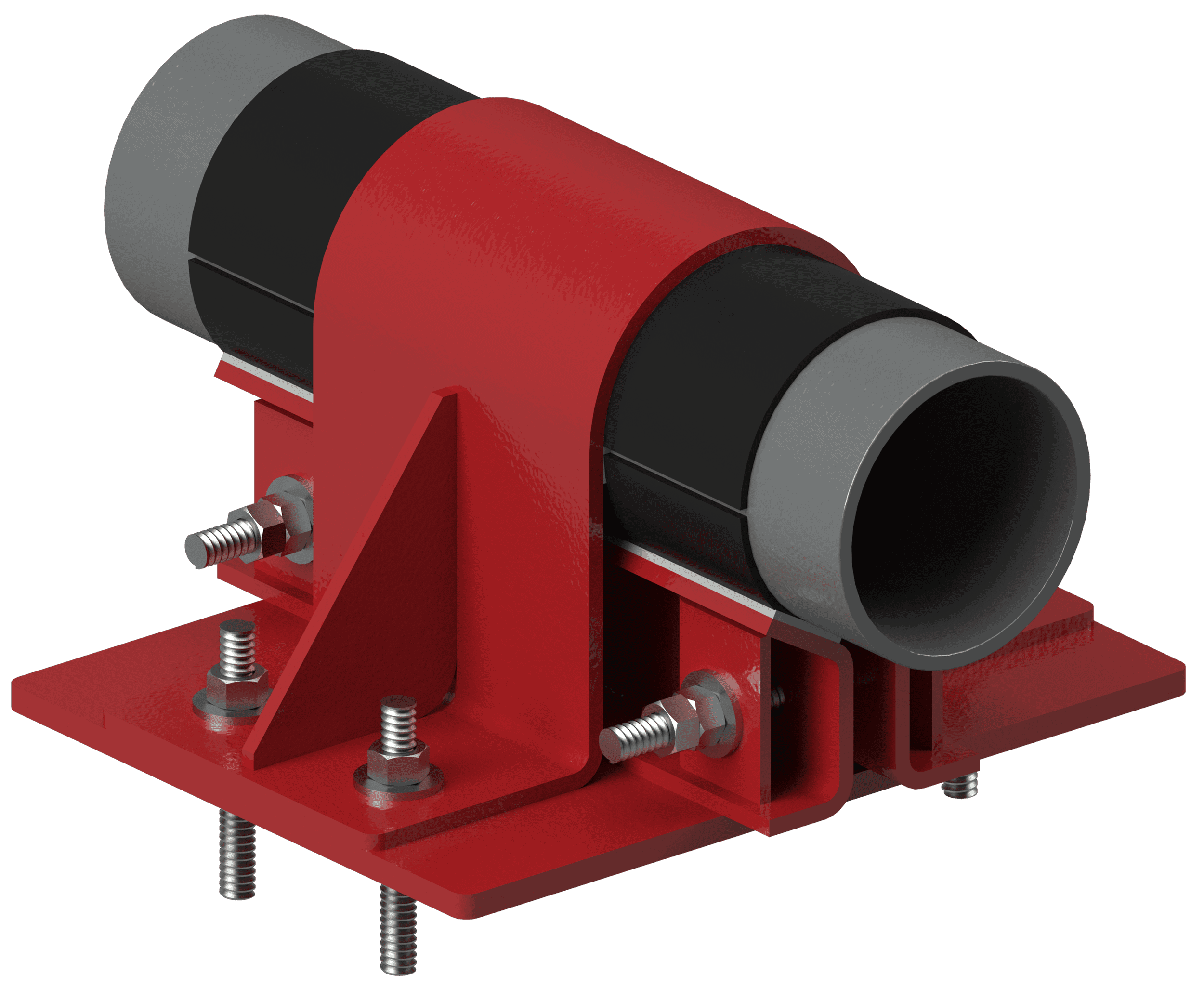

- Pipe Shoes: These include both non-welded and welded options, designed to support pipes while allowing for movement and accommodating thermal expansion. Specialized versions are available for extreme temperatures, such as the RedLineIPS Cold Shoes.

- Pipe Clamps: Available in various forms like Hold Down Clamps and Hanger Clamps, these clamps secure pipes, manage vibrations, and can provide thermal and corrosion protection via the use of isolation liners.

- Shim Block Assembly: This assembly supports alignment and adjustability in piping systems, with components that allow for height adjustment and axial movement to cope with temperature changes.

- Pipe Hangers: Essential for overhead systems, these hangers support pipe movement due to thermal expansion and ensure proper alignment with a variety of components tailored to specific industrial needs.

Design Considerations

The design of pipe supports involves a multitude of considerations to ensure they can withstand environmental and operational demands. Key factors include:

- Load Calculation: Accurate assessment of both static and dynamic loads is crucial to determine the support needed. This includes dead load (weight of the pipe and its components), live load (fluids or gases within the pipe), as well as potential wind and seismic loads in outdoor or exposed installations.

- Material Selection: Materials must be chosen based on the operational environment to resist wear, corrosion, and temperature extremes. Common materials include carbon steel, stainless steel, and various alloys, with finishes that may include paint, galvanization, or special coatings for extra protection.

- Thermal Movements: Supports must accommodate thermal expansion and contraction of pipes due to temperature changes. This is often managed through the use of sliding supports or expansion joints.

Installation and Maintenance

Proper installation is key to the performance of pipe supports. This involves ensuring that supports are positioned correctly to handle loads and movements without compromising the pipe’s integrity. Regular maintenance is also crucial, involving inspections to check for wear, corrosion, and mechanical integrity.

Compliance with Standards

Challenges and Innovations

Despite their critical role, pipe supports face challenges such as environmental stress, mechanical wear, and the need for periodic maintenance. Innovations in materials technology, like RedLineIPS supports equipped with FRP products and other isolation liners, help protect against external corrosion at the pipe support locations (CUPS Corrosion), a major challenge in many industrial environments. These products, alongside predictive maintenance techniques and advanced design methodologies, continue to evolve, enhancing the reliability and efficiency of pipe supports in these demanding settings. For more details on these corrosion-resistant solutions, click here.

The effectiveness of RedLine IPS pipe supports from Cogbill plays a pivotal role in ensuring operational efficiency and safety in petrochemical and gas plants. Our supports are designed to provide precision and durability, accommodating the unique demands of the industry. With their focus on quality and adaptability, RedLine IPS supports ensure that piping systems achieve optimal performance while mitigating risks associated with thermal expansion, vibrations, and environmental conditions. This strategic approach not only enhances the structural integrity of pipelines but also extends their lifespan, making it an essential component for modern industrial applications.

For more information on metallic and non-metallic piping supports, email us.