Brief History and Composition of PTFE

PTFE is a synthetic fluoropolymer composed of carbon and fluorine atoms. The strong carbon-fluorine bonds give PTFE its notable characteristics, including high chemical resistance, low friction, and thermal stability. These properties make PTFE an ideal material for a wide range of uses.

Uses of PTFE

PTFE’s unique properties have made it indispensable in various industries. Some of its common applications include:

- Seals and Gaskets: PTFE is extensively used to manufacture seals and gaskets for valves, pumps, and other equipment operating in harsh chemical and high-temperature environments. Its chemical resistance and ability to withstand temperatures up to 500°F (260°C) make it ideal for such uses.

- Linings and Coatings: PTFE linings are used in metallic pipe supports, pipes, tanks, and other equipment to provide a protective barrier against corrosive chemicals. These linings extend the lifespan of the equipment by preventing chemical attack.

- Bearings and Bushings: PTFE's low coefficient of friction reduces wear and extends the life of bearings and bushings in pumps, compressors, and other machinery.

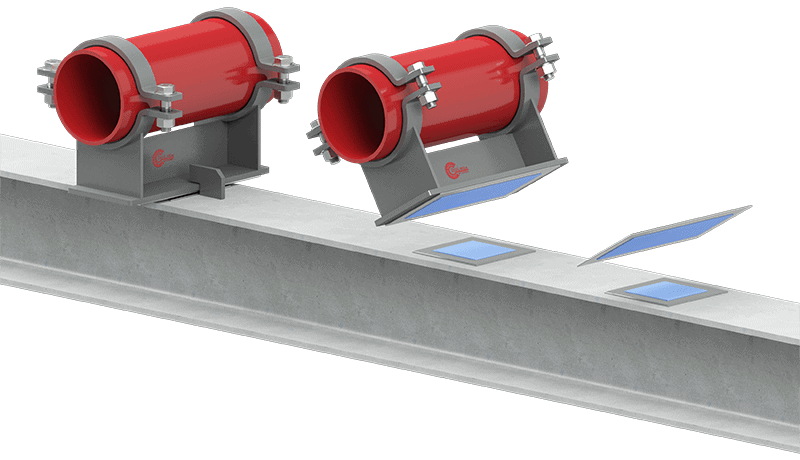

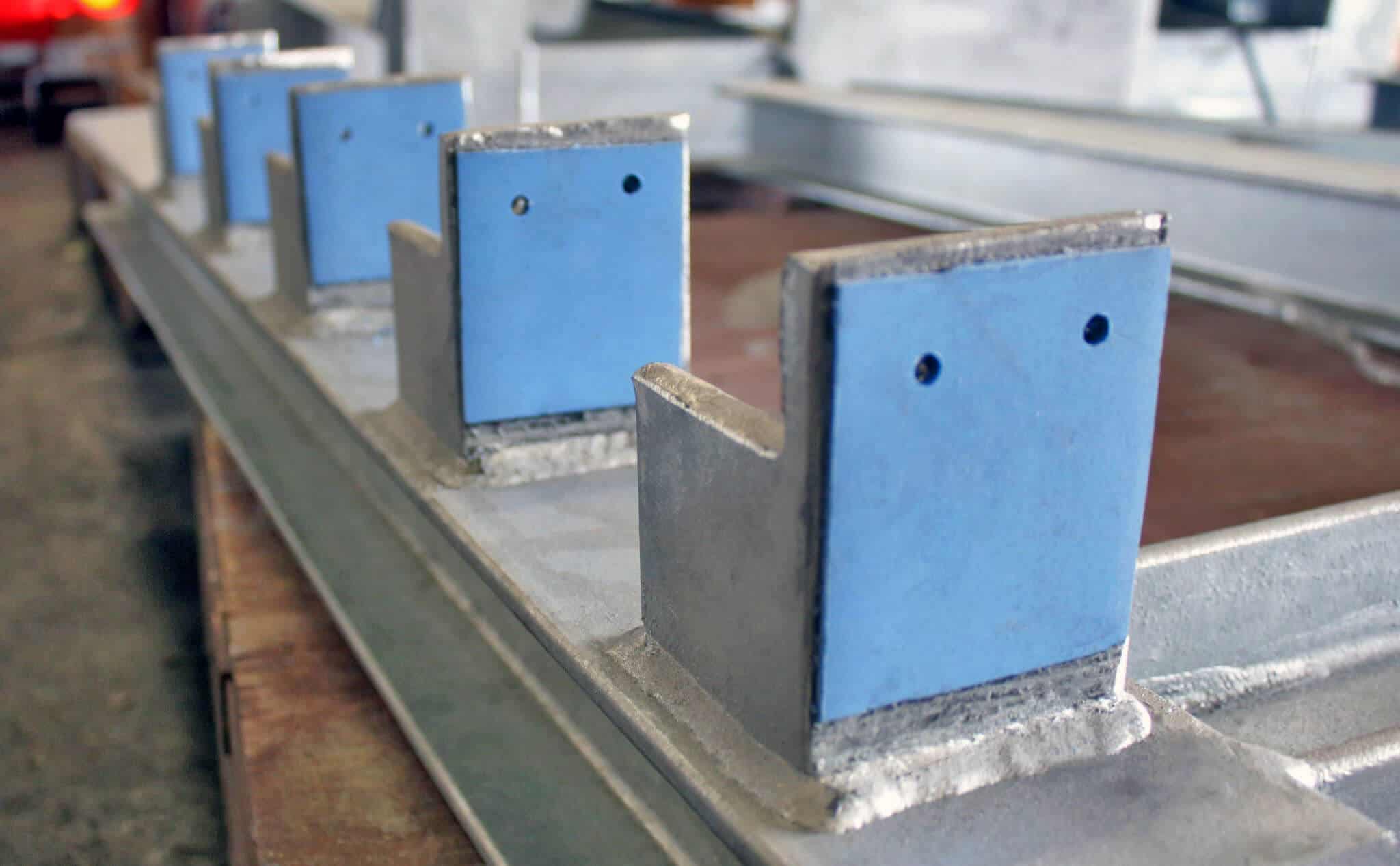

- Slide Plates: In the oil and gas industry, PTFE slide plates facilitate movement and reduce friction in pipelines, tanks, and other equipment.

- Electrical Insulation: PTFE serves as an excellent electrical insulator in cables and wires used in harsh chemical and high-temperature environments.

PTFE in Pipe Supports

Corrosion Prevention

One of the most critical functions of PTFE liners in piping systems is the prevention of corrosion. Corrosion poses a significant threat to metal components within these systems. PTFE liners, with their non-metallic composition, create a protective barrier that insulates pipes from direct contact with metal surfaces. This insulation is instrumental in thwarting the electrochemical reactions responsible for galvanic corrosion.

Galvanic corrosion occurs when dissimilar metals come into contact under specific conditions. In such scenarios, one metal effectively “steals” electrons from another, leading to the degradation of the metal. By using PTFE liners to physically separate pipes from metal supports, the risk of galvanic corrosion is mitigated, thereby prolonging the lifespan of the entire system, both pipe and support.

Vibration Dampening

Piping systems are not static entities; they often encounter vibrations caused by various factors, including fluid flow, rotating equipment, and environmental conditions. These vibrations can lead to metal-on-metal contact, increasing the risk of wear and damage to both pipes and supports. PTFE liners, however, possess the remarkable ability to absorb vibrations and cushion the impact when metal pipes come into contact with each other or with support structures.

This dampening effect not only preserves the structural integrity of the pipes and supports but also reduces the likelihood of costly repairs and maintenance. In systems where vibration is a constant challenge, PTFE liners prove to be indispensable in ensuring long-term performance.

Friction Reduction

Friction wear is another adversary that PTFE liners effectively combat. When pipes scrape against pipe restraints or supports, it can result in the gradual erosion of the pipe’s surface and protective coatings. Over time, this can create small holes and gashes on the pipe’s surface, providing an ideal environment for corrosive substances to accumulate. PTFE liners are engineered to have a low coefficient of friction, allowing pipes to glide smoothly during movement.

This reduction in friction wear not only safeguards the pipes but also preserves the integrity of the pipe supports. By minimizing the abrasive effects of friction, PTFE liners contribute to a longer lifespan for the entire piping system.

PTFE in Slide Plates

Slide plates are used in pipelines, tanks, and other equipment to facilitate movement and reduce friction. PTFE slide plates offer low-friction performance and can be used in a variety of applications in the oil and gas industry. These plates allow for smooth axial movement, accommodating thermal expansion and contraction without compromising the system’s stability. By reducing the friction between moving parts, PTFE slide plates help in maintaining the structural integrity of the piping systems.

Summary of Potential Product Solutions

PTFE’s role in combating CUPS corrosion, vibration, and noise dampening, and friction reduction is invaluable. Its applications in slide plates, pipe support liners, and various industrial components ensure the longevity and efficiency of piping systems. By integrating PTFE into piping support systems, industries can significantly reduce maintenance costs, prevent corrosion-related failures, and enhance the overall performance and reliability of their infrastructure.

For more information on the RedLineIPS PTFE Slide Plates and our metallic pipe support with PTFE liners, email us.