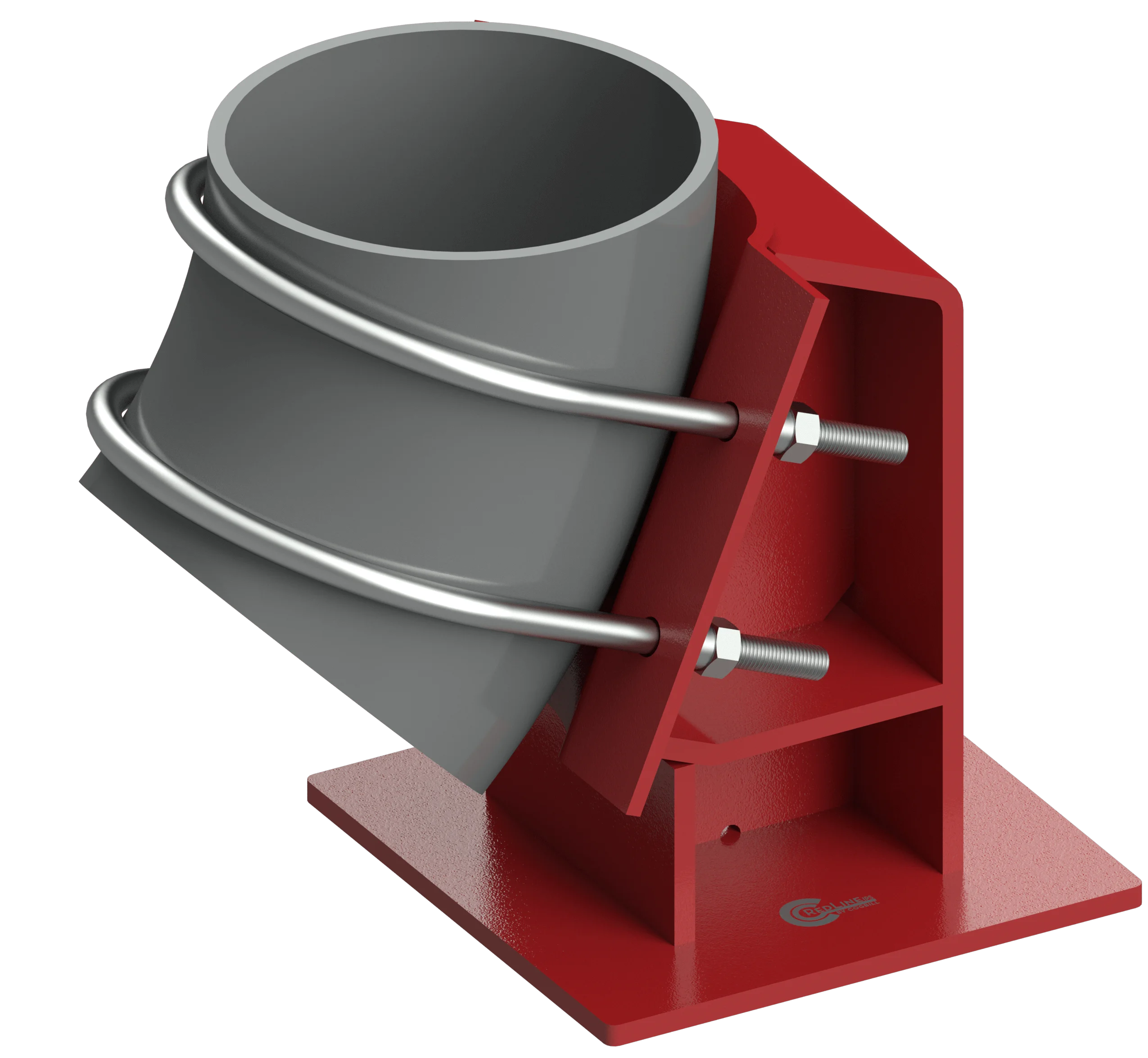

What is a Base ELL Support?

Adjustable and Non-Adjustable Base ELL Pipe Supports, or Elbow Supports, are specialized components designed to support and stabilize piping systems by providing secure cradling and load distribution. The “ELL” refers to the pipe elbow that it supports, and the base plate is used to anchor the support to a structural surface. Adjustable variations include a mechanism, such as a threaded stem or rod, allowing for precise height modifications to accommodate changes in pipe alignment, thermal expansion, and load variations. Non-adjustable variations, on the other hand, provide a fixed height and are used in applications where no further adjustments are needed post-installation. Both types are typically made from durable materials like carbon steel or stainless steel, ensuring reliability and resistance to corrosion in demanding industrial environments.

Design and Function

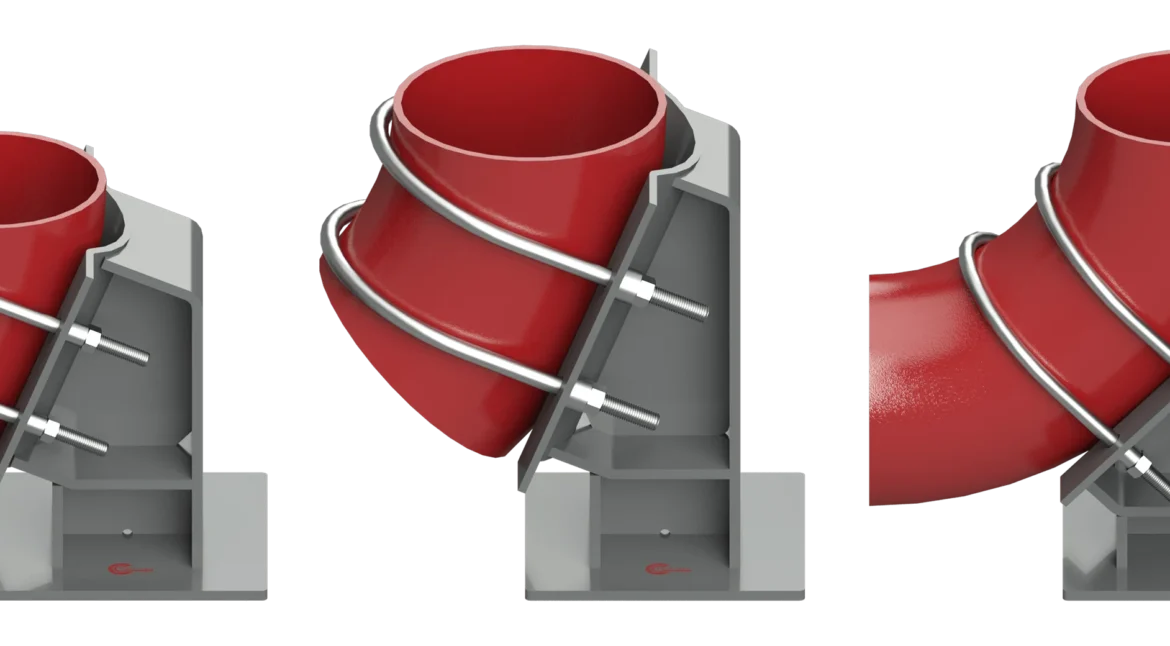

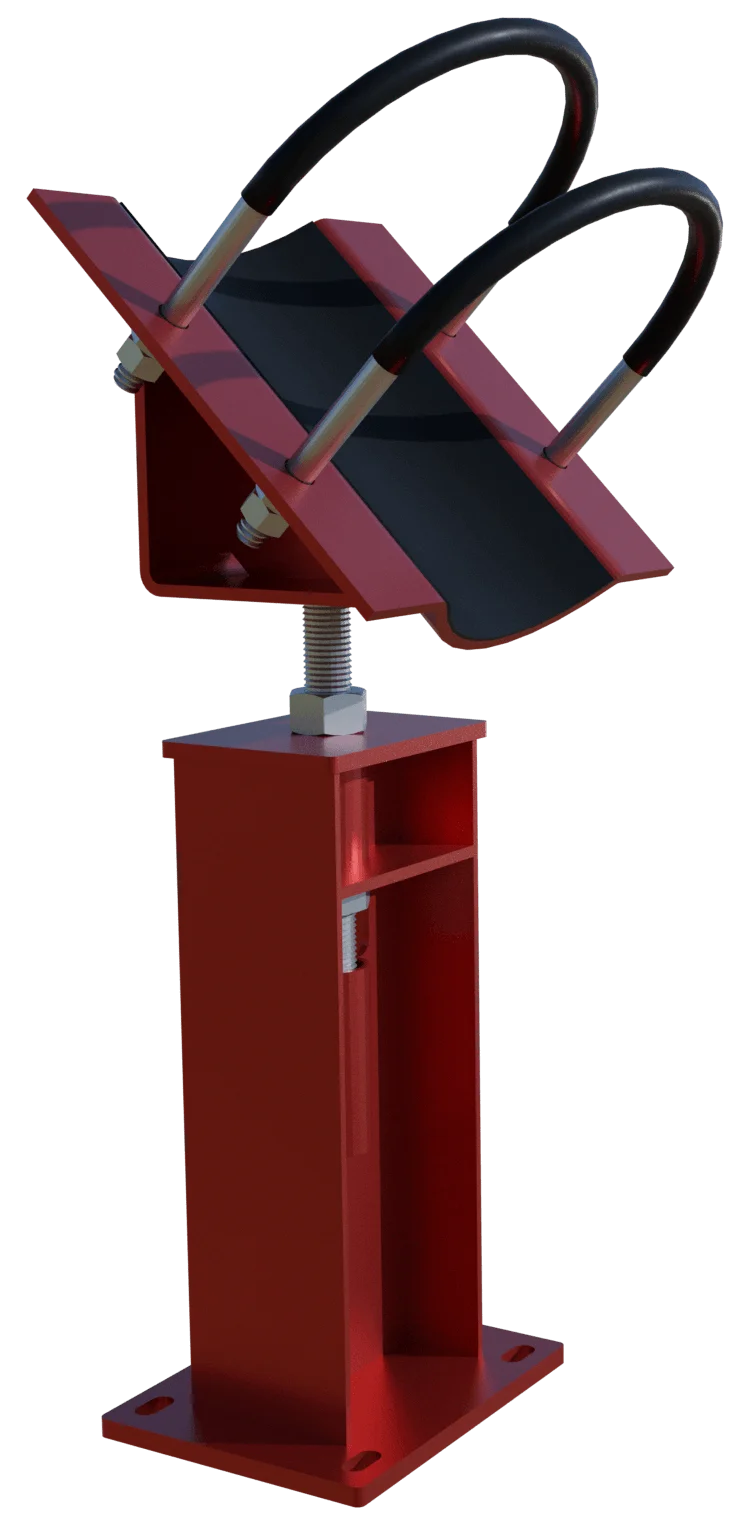

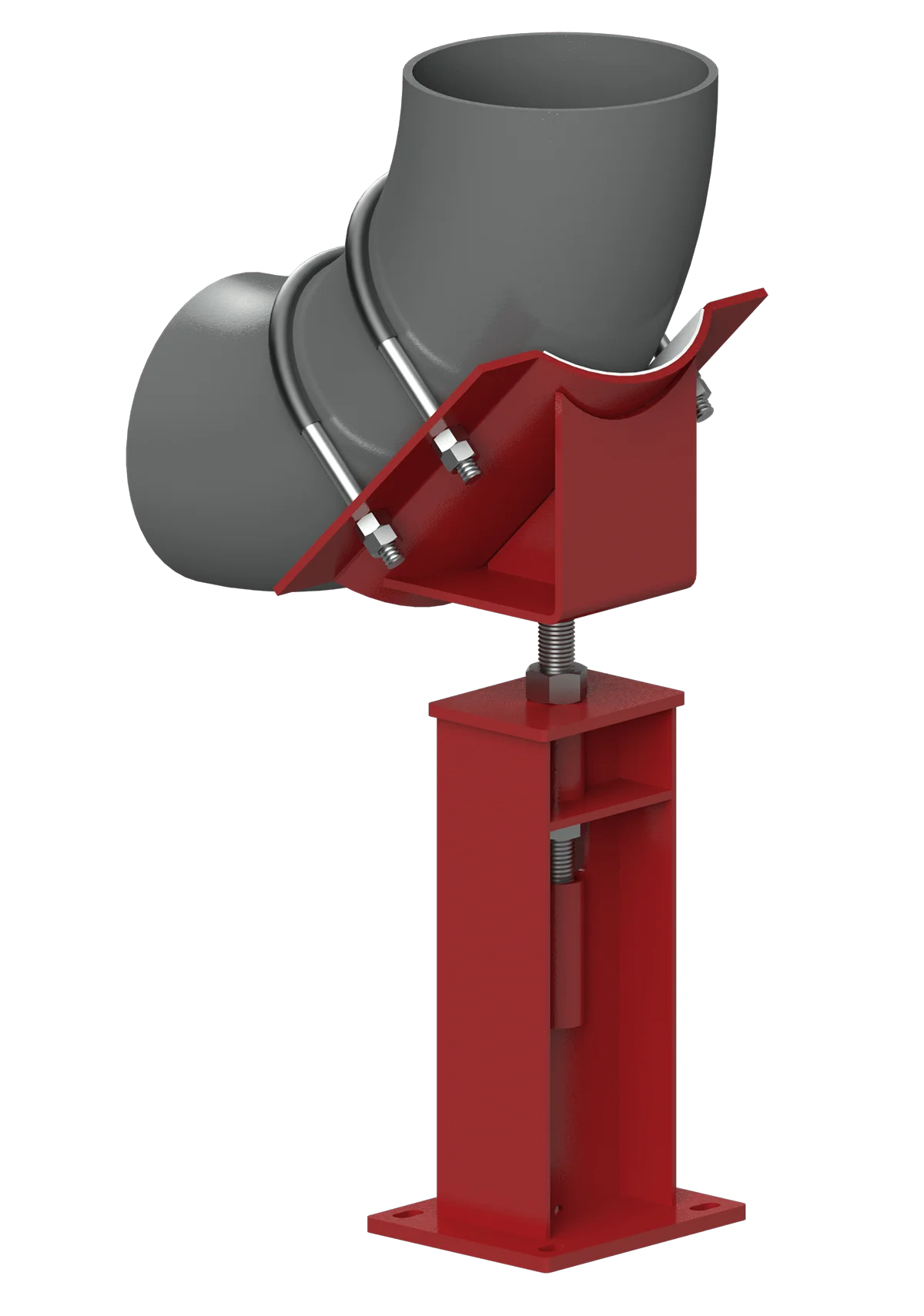

An Adjustable Base ELL Pipe Support typically consists of several key components, including the base plate, vertical column, and adjustable support head. These supports allow for vertical adjustments, enabling engineers to fine-tune the height based on specific system requirements. By accommodating vertical movement, they prevent undue stress on the piping system, especially in applications where the pipes may experience thermal expansion, contraction, or vibrations due to operational conditions.

The adjustable base allows for compensation in installation tolerances or shifting over time, while the ELL pipe support head maintains the pipe in place with minimal friction, reducing wear and corrosion potential. In petrochemical plants, where high-pressure pipelines may carry hazardous or high-temperature materials, the ability to adjust and maintain support alignment is essential for operational safety and system integrity.

Applications in Petrochemical Plants

In petrochemical plants, where piping systems are exposed to high temperatures, chemicals, and pressure variations, Adjustable Base ELL Pipe Supports play a key role. They support critical sections of the piping infrastructure by managing vertical loads, reducing the impact of thermal expansion, and ensuring that alignment issues are minimized. They are frequently used in high-risk areas where piping stability is essential, such as near heat exchangers, pressure vessels, and reactors.

These pipe supports are often designed to accommodate various piping sizes, materials, and load ratings specific to the petrochemical industry. The adjustable feature allows them to support the piping system efficiently even in environments that are prone to settlement, vibration, or thermal changes.

Types of Base ELL Supports

Base ELL Pipe Supports are designed to provide stable and secure support for piping systems in industrial applications. They are available in both adjustable and non-adjustable configurations, each serving specific purposes based on installation requirements and operational needs.

Adjustable Base Elbow Pipe Supports

- Threaded Stem Adjustable ELL Support: This support features a threaded stem or rod, enabling precise vertical adjustments to align the pipe and accommodate thermal expansion. It is ideal for applications requiring fine-tuning post-installation to maintain system integrity.

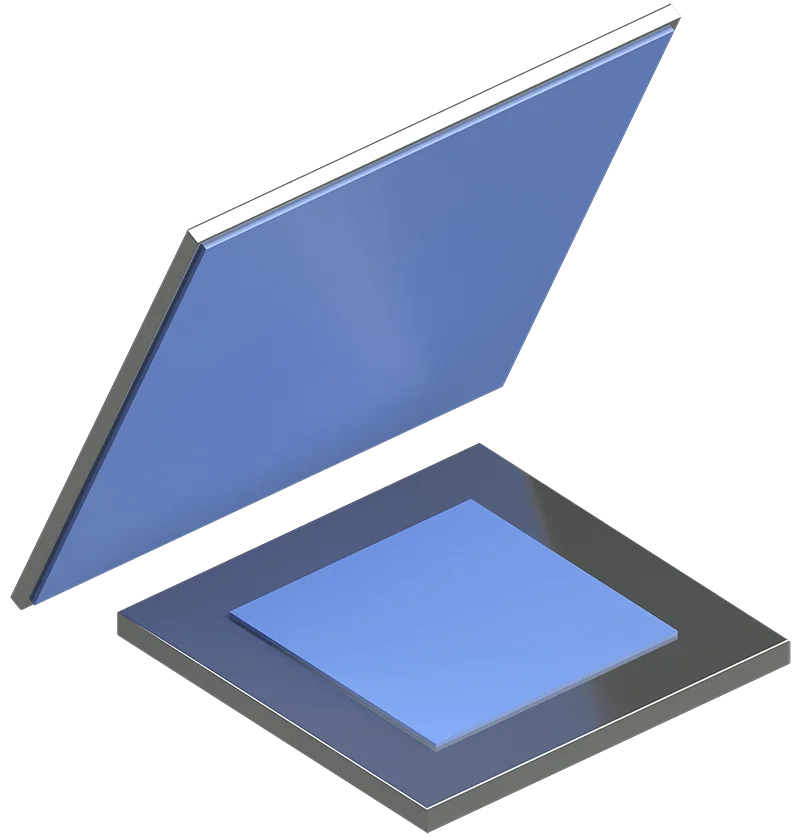

- Slotted Base Adjustable ELL Support: These supports come with a slotted base plate that allows for horizontal adjustments of the pipe position, providing flexibility in lateral alignment without affecting vertical stability. Slide plates can be incorporated to reduce friction during horizontal movement, making them suitable for systems experiencing slight thermal expansion.

- Spring-Loaded Adjustable ELL Support: Designed with a spring mechanism, these supports automatically adjust to vertical and lateral forces caused by thermal variations. They help reduce stress on the piping system in environments with frequent temperature changes, ensuring stability and flexibility.

- Combination Adjustable ELL Support: Combining features like a threaded stem and slotted base, this type offers both vertical and horizontal adjustability, making it versatile for complex piping configurations that require multi-directional alignment. Slide plates may be included to facilitate smooth movement in both directions.

- Heavy-Duty Adjustable ELL Support: Built for larger diameter pipes and heavy loads, these supports have reinforced components and robust adjustment mechanisms to handle increased weight and forces in demanding industrial applications. They can include slide plates for applications where horizontal movement needs to be accommodated alongside heavy vertical loads.

Non-Adjustable Base Elbow Pipe Supports

- Standard ELL Support: A simple, cost-effective, non-adjustable support used for general piping applications, providing a fixed height that ensures stable support and alignment without the need for post-installation adjustments.

- Welded Base ELL Support: The ELL bracket is welded directly to the base plate, creating a strong and permanent connection. It is ideal for applications with minimal movement and high durability requirements.

- Saddle-Type ELL Support: Featuring a curved ELL bracket that cradles the pipe, this type distributes the load evenly, reducing stress on both the pipe and support. It provides a fixed, stable base for applications where vertical adjustments are not needed.

- Hold-Down ELL Support: This variation includes a top plate or U-bolt to secure the pipe firmly, preventing vertical and lateral movement. It is commonly used in high-vibration environments to maintain stability and alignment.

- Fixed ELL Supports: These non-adjustable supports provide a stable base with minimal movement, making them suitable for static conditions where post-installation adjustments are not required.

- Sliding ELL Supports: Designed to allow lateral movement while maintaining vertical load support, these supports are equipped with slide plates made of low-friction materials like PTFE. They are ideal for pipes experiencing significant thermal expansion and contraction, ensuring smooth horizontal movement and reducing stress on the piping system.

- Spring-Loaded ELL Supports: Providing dynamic support, these non-adjustable supports incorporate spring mechanisms that respond to vertical and lateral forces due to thermal variations, ensuring the integrity and stability of the piping system in fluctuating temperature environments.

Integration with RedLineIPS Pipe Supports

RedLineIPS, known for its innovative solutions in both metallic and non-metallic pipe supports, offers a range of highly durable and customizable products for supporting industrial piping systems. RedLineIPS Adjustable Base ELL Pipe Supports are engineered with precision to meet the demanding requirements of petrochemical plants, where high-performance and corrosion resistance are critical.

The RedLineIPS Adjustable ELL Heavy-Duty Supports are designed to ensure not only stability but also longevity under harsh industrial conditions. By using high-quality steel or composite materials, RedLineIPS ensures that its supports withstand chemical exposures and high temperatures common in petrochemical environments.

RedLineIPS ELL supports are designed for easy installation and adjustment, providing a reliable, maintenance-friendly solution. The company’s supports feature corrosion-resistant coatings and are designed to allow easy integration with existing piping infrastructure, improving the operational lifespan of the system.

Benefits of Adjustable Base Elbow Supports

- Flexibility: The adjustable height feature allows the support to accommodate varying pipe elevations, making installation easier and reducing on-site adjustments.

- Stress Reduction: By ensuring proper pipe alignment, these supports reduce stress on the system caused by misalignment or uneven load distribution.

- Thermal Expansion Accommodation: In applications with frequent temperature fluctuations, such as petrochemical plants, these supports allow for controlled movement and mitigate the effects of thermal expansion.

- Corrosion Resistance: Modern adjustable supports, especially those offered by RedLineIPS, are lined using corrosion-resistant materials, making them ideal for environments that involve chemicals or high humidity.

- Load Distribution: Adjustable Base ELL Pipe Supports help distribute the weight of the pipes evenly across the system, preventing undue strain on any single point of the piping infrastructure.

- Durability and Low Maintenance: RedLineIPS supports are built for high-durability applications, with minimal need for frequent maintenance, reducing downtime in petrochemical facilities.

Considerations for Selecting Adjustable Base Elbow Pipe Supports

When selecting adjustable base ELL pipe supports, engineers and designers must consider several factors:

- Material Selection: The material of the support must be compatible with the piping and withstand the environmental conditions of the petrochemical plant, including high temperatures, corrosive chemicals, and pressure variations. RedLineIPS provides both metallic and non-metallic options that can be tailored to specific applications.

- Load Requirements: Proper load rating is crucial for ensuring that the pipe support can handle the weight and stress of the piping system without failing. Adjustable supports from RedLineIPS are available in a variety of load ratings to match the demands of each specific installation.

- Thermal Expansion: Systems that experience temperature fluctuations may require supports that can accommodate thermal expansion. Adjustable Base ELL Pipe Supports with sliding or spring-loaded components provide the necessary flexibility to handle these changes.

- Corrosion Resistance: For petrochemical plants, where exposure to harsh chemicals and moisture is common, corrosion-resistant coatings and materials are vital for long-lasting pipe supports.

- Ease of Installation and Maintenance: Supports should be easy to install and adjust, especially in environments where frequent maintenance is required. RedLineIPS designs their adjustable base ELL pipe supports for easy access and minimal maintenance, reducing downtime.

RedLineIPS offers a comprehensive range of both metallic and non-metallic pipe supports, including Base ELL Pipe Supports, engineered to meet the unique challenges of industrial applications. These supports, built for durability and ease of maintenance, are designed to withstand the rigors of petrochemical environments, making them an essential component of any industrial piping system.

For more information about RedLineIPS pipe supports, visit their website at RedLineIPS.com.