Introduction

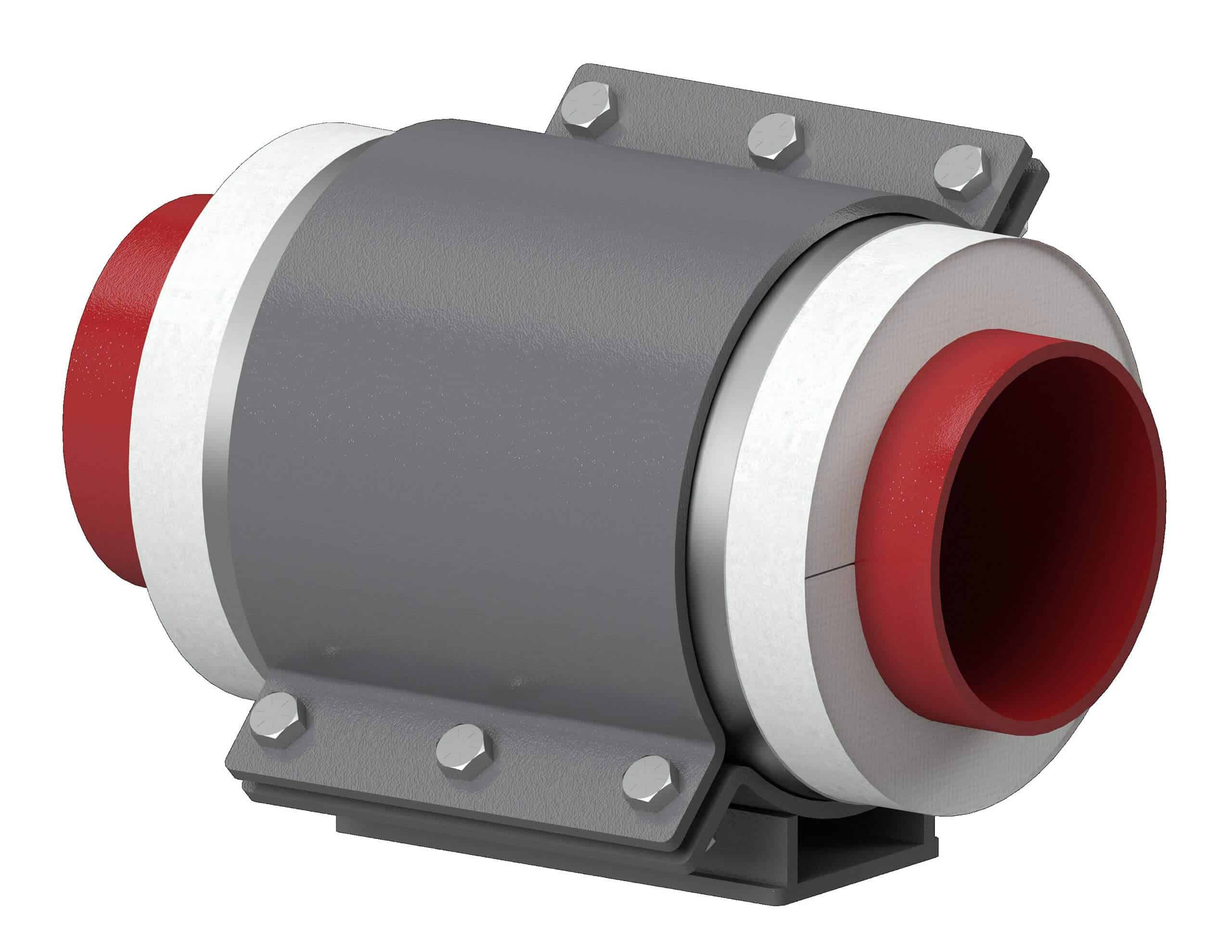

In the petrochemical and liquefied natural gas (LNG) industries, the integrity and efficiency of piping systems are paramount. Pre-insulated pipe shoes, are essential components that ensure these systems operate effectively, especially when transporting substances at extremely low temperatures. This guide delves into the specifics of pre-insulated pipe shoes, their composition, necessity, functionality, and benefits, with a focus on the demanding conditions of the petrochemical and LNG sectors.

The main purpose of pre-insulated pipe shoes is to support and hold the weight of the pipeline while also providing a thermal barrier to minimize heat transfer between the pipe and its surroundings. They are typically used in situations where there is a need to maintain the temperature of the fluid flowing through the pipe or to prevent heat loss or gain from the surrounding environment.

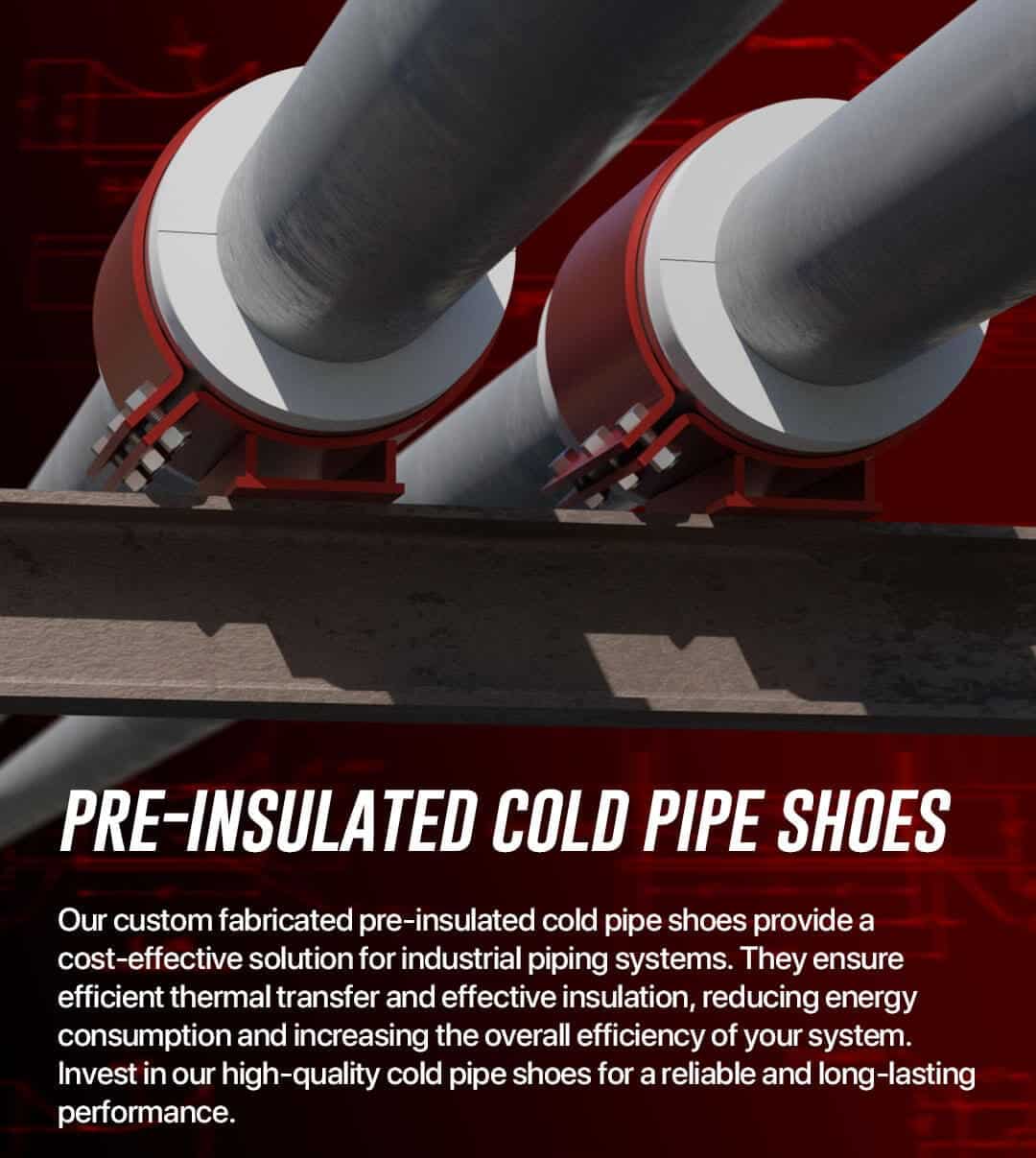

Importance of Pre-Insulated Pipe Shoes

Pre-insulated pipe shoes are crucial for several reasons:

- Thermal Insulation: They prevent heat transfer between the pipe and the surrounding structure, maintaining the fluid's temperature and minimizing energy loss.

- Structural Integrity: These shoes reduce thermal expansion and contraction, preventing stress and damage to the piping system.

- Corrosion Prevention: By insulating the pipe, these shoes protect against external corrosion.

- Vibration and Noise Dampening: They help in reducing vibrations and noise, enhancing system performance and longevity.

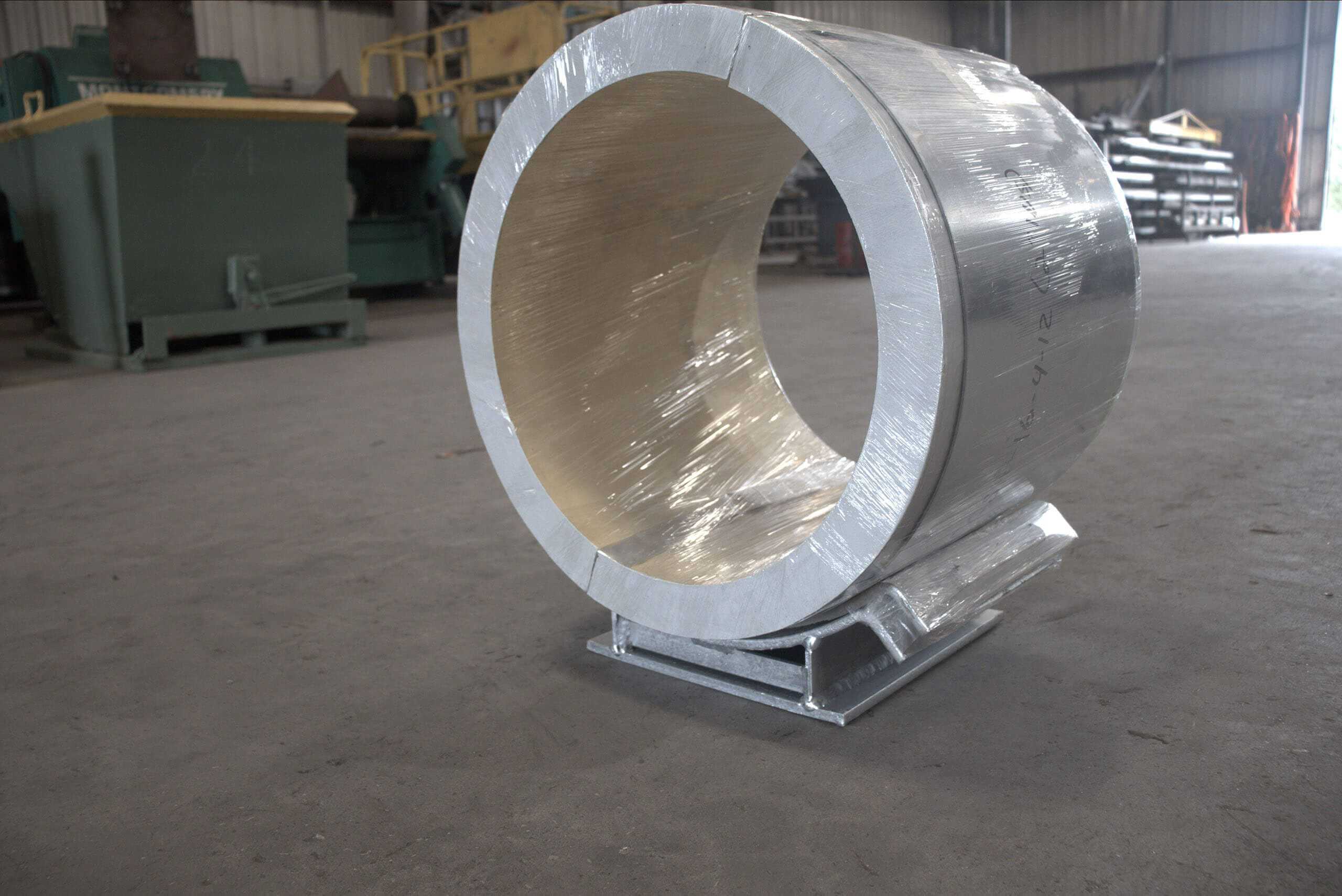

Material Composition of RedLineIPS Pre-Insulated Pipe Shoes

- Structural Components:

- Carbon Steel: Widely used due to its high strength and durability. Suitable for temperatures up to 370°C (700°F).

- Stainless Steel: Offers excellent corrosion resistance, making it ideal for harsh environments. Suitable for temperatures ranging from -200°C (-328°F) to 800°C (1472°F).

- Composite Materials: Lightweight and strong, often used where weight reduction is crucial. Composites can handle a wide range of temperatures depending on their specific composition.

- Insulating Materials:

- Polyurethane Foam (PUF): Known for its excellent thermal insulation properties, PUF is suitable for temperatures ranging from -200°C (-328°F) to 100°C (212°F).

- Calcium Silicate: Offers high compressive strength and is resistant to temperatures up to 1000°C (1832°F), making it ideal for high-temperature applications.

- Marinite®: A non-asbestos, high-temperature insulation material with excellent thermal performance, suitable for temperatures up to 1050°C (1922°F).

- Aerogels: Advanced insulation materials that provide superior thermal resistance with extremely low thermal conductivity. They are effective across a broad temperature range, from -200°C (-328°F) to 650°C (1202°F).

Types of RedLineIPS Pre-Insulated Pipe Shoes

- Welded Shoes for Cryogenic Service:

- Description: Directly welded to pipes conveying cryogenic fluids, ensuring a robust and seamless connection.

- Applications: Essential in LNG facilities and cryogenic storage.

- Materials: Typically made from low-temperature alloys such as stainless steel, suitable for temperatures as low as -196°C (-321°F).

- Cryogenic Pipe Supports with Insulation:

- Description: Incorporates insulation materials to prevent thermal conductivity between the shoe and the pipe, maintaining extremely low temperatures.

- Applications: Used in pipelines where temperature differentials are significant.

- Materials: Utilizes specialized insulating materials like aerogels or PUF.

- Adjustable Cryogenic Shoes:

- Description: Designed for flexibility in accommodating different pipe sizes and facilitating adjustments in cryogenic environments.

- Applications: Suitable for systems with varying pipe sizes or where frequent modifications are necessary.

- Materials: Made from low-temperature alloys and advanced composites.

How Pre-Insulated Pipe Shoes Work

Pre-insulated pipe shoes function by providing a stable and insulated base for pipes, distributing loads evenly and preventing direct heat transfer. Here’s how they achieve this:

- Load Distribution: The structural component supports the pipe's weight, distributing it across a larger area to reduce stress.

- Thermal Barrier: The insulating layer reduces thermal conductivity, maintaining the desired temperature within the pipe and protecting the support structure from thermal damage.

- Expansion Accommodation: The design allows for controlled movement due to thermal expansion and contraction, preventing stress and damage.

Applications in the Petrochemical and LNG Industries

- LNG Terminals:

- Usage: Critical for supporting pipes that transport liquefied natural gas, where maintaining extremely low temperatures is essential.

- Requirements: Must handle temperatures as low as -162°C (-260°F) and prevent heat transfer that could compromise LNG quality.

- Petrochemical Plants:

- Usage: Used in various stages of chemical processing where temperature control and corrosion resistance are vital.

- Requirements: Must withstand both low and high temperatures depending on the process stage, ranging from -50°C (-58°F) to 500°C (932°F).

- Cryogenic Storage:

- Usage: Ensures the integrity of pipelines conveying cryogenic substances in storage tanks.

- Requirements: Must maintain extremely low temperatures and prevent thermal bridging that could lead to product loss.

Considerations for Selection of RedLineIPS Shoes

Choosing the right pre-insulated pipe shoe involves several critical factors:

- Temperature Range: Ensure the materials used can withstand the specific temperature requirements of your application.

- Insulation Requirements: Balance the need for thermal insulation with the load-bearing capabilities of the shoe.

- Material Compatibility: Select materials that are compatible with the conveyed substances to prevent chemical reactions and ensure longevity.

Installation and Maintenance

Installation:

- Alignment: Ensure proper alignment with the pipe and the support structure.

- Securing: Use appropriate methods (welding, bolting, clamping) to secure the shoe in place.

- Leveling: Ensure the shoe is level to prevent uneven load distribution.

Maintenance:

- Inspection: Regularly check for signs of wear, corrosion, or damage.

- Cleaning: Keep the shoes clean to prevent debris accumulation that could impact performance.

- Repairs: Address any issues promptly to maintain the structural integrity and functionality.

Pros and Cons of Pre-Insulated Pipe Shoes

Pros:

- Thermal insulation: The ability to provide thermal insulation enables them to reduce heat loss or gain from the pipeline, maintaining the desired temperature of the fluid being transported. This can result in energy savings and more efficient operation of the system.

- Structural support: They provide adequate support and load-bearing capacity for pipelines. This helps distribute the weight of the pipeline, preventing sagging, bending, or excessive stress. This ensures the integrity and longevity of the pipeline system.

- Corrosion protection: The outer casing or shell of pre-insulated pipe shoes is typically made of durable materials such as steel or stainless steel, providing protection against corrosion. This helps prolong the lifespan of the pipeline and reduces maintenance requirements.

- Flexibility: Pre-insulated pipe shoes come in various designs and configurations to accommodate different pipeline systems and requirements. They can be customized to fit specific pipe sizes, insulation thicknesses, and load capacities. This flexibility allows for proper installation and alignment, ensuring optimal performance.

Cons:

- Cost: Pre-insulated pipe shoes can be more expensive than traditional pipe supports or hangers due to the additional materials and insulation incorporated into their design. The cost of materials, fabrication, and installation should be taken into consideration when evaluating the overall project budget.

- Maintenance: While pre-insulated pipe shoes offer corrosion protection, regular inspection and maintenance are still necessary to ensure their continued effectiveness. The insulation layer should be inspected for any damage or degradation, and any issues should be addressed promptly to maintain the thermal performance.

- Limited movement: Depending on the type of pre-insulated pipe shoe used, there may be limitations on the movement of the pipeline. Fixed pipe shoes restrict movement entirely, while sliding or spring-type shoes allow for limited axial or vertical movement. It's important to consider the anticipated thermal expansion and contraction of the pipeline when selecting the appropriate type of pipe shoe.

- Installation Complexity: Pre-insulated pipe shoes require proper installation techniques to ensure their effectiveness and performance. The insulation layer needs to be correctly aligned and secured, and the load-bearing capacity should be verified to meet the specific requirements of the pipeline system. Improper installation can lead to reduced insulation performance or structural issues.

Pre-insulated pipe shoes are indispensable in the petrochemical and LNG industries, providing critical support, insulation, and protection for piping systems. With materials tailored to withstand extreme temperatures and harsh environments, RedLineIPS pre-insulated pipe shoes ensure the efficiency, safety, and longevity of industrial infrastructure. RedLineIPS offers a range of high-quality, customizable pre-insulated pipe shoes designed to meet the rigorous demands of these sectors. By understanding the composition, functionality, and benefits of these components, industry professionals can make informed decisions to optimize their piping systems and achieve reliable, long-term performance.

For further information on RedLineIPS pre-insulated pipe shoes and other piping solutions, email us.